The global vacuum evaporators market is witnessing consistent growth, fueled by growing demand in industries like wastewater treatment, food and beverage, pharmaceuticals, and chemicals. The industry is estimated to be worth USD 3.24 billion in 2025 and reach USD 6.49 billion in 2035 at a CAGR of 7.5%.

The increasing demand for effective water and wastewater management solutions, strict environmental laws, and developments in evaporation technologies are among the major drivers of segment growth.

The vacuum evaporators segment recorded significant growth in 2024, with higher adoption rates driven by the increasing demand in industries focusing on wastewater treatment, recovery of resources, and green industrial processes. There was increased demand from the pharma and food processing industries for effective concentration and purification of solutions.

Local demand shall remain robust across North America, Europe, and Asia-Pacific and from emerging nations as they upgrade their industrial wastewater treatment facilities. Innovation, such as power-saving multi-effect evaporators and hybrid vacuum systems, is also molding the segment trajectory.

Market Metrics

| Metric | Value |

|---|---|

| Industry Size (2025E) | USD 3.24 billion |

| Industry Value (2035F) | USD 6.49 billion |

| CAGR | 7.5% |

Explore FMI!

Book a free demo

Key Priorities of Stakeholders

Regional Variance:

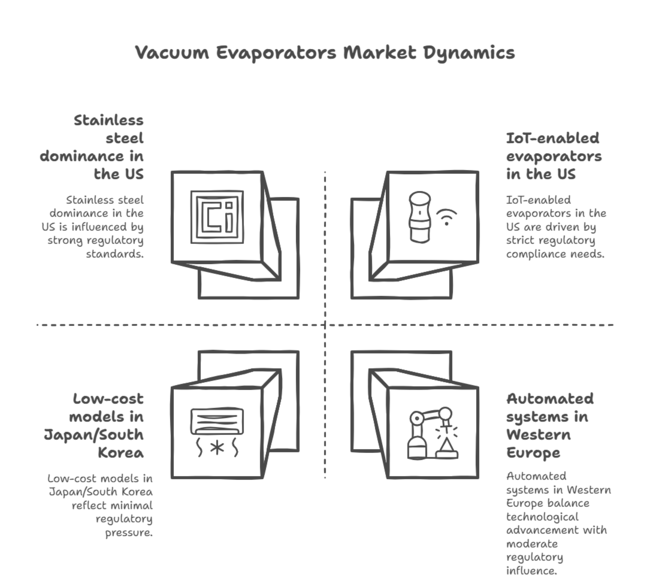

Adoption of Smart & Automated Vacuum Evaporators

Material Preferences for Vacuum Evaporators

Price Sensitivity & Cost Challenges

Supply Chain & Value Chain Challenges

Future Investment Priorities

Regulatory Landscape & Compliance Challenges

Conclusion: Regional Variance vs. Industry Consensus

| Country | Regulation |

|---|---|

| United States | The Environmental Protection Agency (EPA) enforces wastewater treatment and zero-liquid discharge (ZLD) regulations, driving demand for high-efficiency vacuum evaporators. The Department of Energy (DOE) promotes energy-efficient industrial equipment, influencing evaporator design. |

| Canada | The Canadian Council of Ministers of the Environment (CCME) sets industrial effluent discharge limits, encouraging the adoption of advanced evaporation technologies. The ENERGY STAR Canada program supports energy-efficient evaporator systems. |

| India | The Central Pollution Control Board (CPCB) regulates industrial wastewater discharge, pushing industries to adopt vacuum evaporation solutions. Government initiatives promote sustainable and resource-efficient evaporator technologies. |

| European Union | The EU Water Framework Directive and Industrial Emissions Directive (IED) enforce strict wastewater treatment standards, driving innovation in low-energy vacuum evaporators. The Ecodesign Directive mandates energy-efficient evaporator designs. |

| China | The China Compulsory Certification (CCC) requires quality control and compliance for vacuum evaporators used in industrial wastewater treatment. Environmental policies encourage the adoption of recyclable materials and energy-saving evaporation technologies. |

| 2020 to 2024 (Past Industry Trends) | 2025 to 2035 (Future Industry Projections) |

|---|---|

| Moderate growth with a CAGR of ~7.5%, driven by regulatory compliance and industrial wastewater treatment needs. | Accelerated growth due to stricter environmental regulations, adoption of ZLD systems, and technological advancements. |

| Adoption of multi-effect and mechanical vapor recompression (MVR) evaporators for energy savings. | AI-powered automation, IoT-enabled monitoring, and hybrid evaporation technologies for improved efficiency. |

| Compliance with regional wastewater discharge laws, driving demand for high-efficiency systems. | Stricter global regulations on industrial emissions, water reuse, and carbon neutrality mandate advanced vacuum evaporator adoption. |

| Key industries: chemical processing, pharmaceuticals, food & beverage. Adoption driven by wastewater treatment needs. | Wider adoption in semiconductors, electronics, and energy sectors, focusing on water recycling and sustainability. |

| Predominantly stainless-steel evaporators for corrosion resistance. | Increased use of hybrid materials (composites & alloys) for lighter, energy-efficient designs. |

| Limited automation and predictive maintenance capabilities. | High adoption of real-time monitoring, AI-based efficiency optimizations, and predictive failure detection. |

| Energy-efficient designs emerging, but adoption remains limited due to cost concerns. | Strong emphasis on low-energy, carbon-neutral evaporators driven by government incentives and sustainability goals. |

| North America & Europe lead adoption due to regulatory pressures; Asia-Pacific growing due to industrial expansion. | Asia-Pacific dominates growth with rising industrial wastewater regulations, while Europe focuses on carbon-neutral systems. |

| High initial CAPEX concerns slow adoption, with a preference for low-cost models. | Greater investment in advanced, automated evaporators with a focus on long-term ROI and operational savings. |

Heat pump evaporators, thermal evaporators, and mechanical vapor recompression (MVR) evaporators make up the vacuum evaporator landscape. Of these, MVR evaporators are the biggest segment, as they cause considerable energy savings by vapor recycling. Such systems are extremely favored in the pharmaceutical, food processing, and wastewater treatment industries, where cost efficiency of operations is a prime concern.

Heat pump evaporators are becoming increasingly popular because they can be used at lower temperatures which making them ideal for heat-sensitive products in applications such as food and drink. Energy-efficient designs, particularly in companies aiming to reduce emissions and wastewater, pose a challenge to thermal evaporators, despite their affordability.

With stringent environmental regulations and an increased focus on zero-liquid discharge (ZLD) technologies, wastewater treatment is the fastest-growing application area for vacuum evaporators.

The product processing segment represented by food & beverage, pharmaceuticals, and the chemical industry is witnessing growth owing to the growing concern of businesses regarding product purity, which in turn will promote solvent recovery. Vacuum evaporators are providing efficiency and sustainability in these sectors.

And other applications-such as metal recovery and desalination-are emerging as niche opportunities, fueled by industrial expansion and resource optimization.

Food and beverage applications, which use vacuum evaporators for processing juice concentration, dairy, and flavoring, are among the fastest-growing end-use sectors.

The electronics and semiconductors industry is also exhibiting higher adoption, mainly owing to the need for ultrapure water and clean chemical concentration processes.

Vacuum evaporators are crucial in the chemical & petrochemical sector due to their necessity for wastewater management, solvent recovery, and process efficiency.

On the other hand, the automotive and energy & power sectors are witnessing steady adoption growth also from regulatory aspects regarding industrial waste disposal and sustainability.

The market in North America is being dominated by the United States due to the presence of a large consumer base, large-scale industrial vacuum evaporator manufacturers, and strong demand from end-user industries.

Companies are focusing on upgrading their facilities with technological advancements and sustainability in a rapidly changing industry environment.

The USA industrial sector is well-capitalized and invests heavily in research and development to enhance both product efficiency and environmental compliance. The vacuum evaporators landscape in the USA also benefits from the presence of key players as well as an established supply chain.

FMI opines that the United States vacuum evaporators sales will grow at nearly 6.8% CAGR through 2025 to 2035.

The UK vacuum evaporators landscape will contributing to the growth and continued success of established industry players and providing opportunities for companies to secure segment share.

Predictive analytics work well for customer behavior and industry strategies, and innovative product offerings and a profound understanding of consumer preferences have all contributed to this upward trend.

The UK also has a strong commitment to environmental protection, prompting companies to develop energy-saving and environmentally friendly vacuum evaporator solutions. This excellent combination of technology and regulatory standards makes it an easier entry point to the UK than other sectors.

FMI opines that the United Kingdom vacuum evaporators sales will grow at nearly 6.5% CAGR through 2025 to 2035.

The result of ongoing economic growth, government support, and a stable workplace, France is anticipated to represent one of the higher growth rates in the European vacuum evaporators sector.

The International Monetary Fund, creating a steady level of consumer confidence and enhancing the prospects of the segment. More companies are looking for long-term growth opportunities through investment in next-gen technologies and growing product mixes for industrial needs.

A range of sectors are adopting advanced vacuum evaporator systems due to France's focus on environmental regulations and sustainability.

FMI opines that the France vacuum evaporators sales will grow at nearly 7.0% CAGR through 2025 to 2035.

Post-pandemic recovery of Germany in the vacuum evaporators landscape is anticipated in 2025. The German industry keeps adjusting to changing segment conditions, as it expects GDP growth of 0.9%.

This places companies adopting sustainability at a significant advantage in the country, with its robust process engineering capabilities and an ethos for environmentally friendly solutions.

When it comes to high-quality vacuum evaporators, many manufacturers have German influences. Germany emphasizes energy efficiency and compliance with strict environmental standards.

FMI opines that the Germany vacuum evaporators sales will grow at nearly 7.2% CAGR through 2025 to 2035.

The strong process engineering capabilities, affordable manufacturing, and availability of deep skilled labor enable a strong outlook for Italy's vacuum evaporators landscape. Pulling from the country's industrial legacy and machinery sector expertise, vacuum evaporators are made at high standards.

To gain global competitive advantages, Italian companies are working towards creating innovation and customized solutions that serve specific needs of the industry. Moreover, their focus on sustainable manufacturing practices and compliance with strict European Union regulations only strengthens their position in the sector.

FMI opines that the Italy vacuum evaporators sales will grow at nearly 6.8% CAGR through 2025 to 2035.

The South Korea Vacuum Evaporators landscape is growing, with top players launching new innovations and expanding their product portfolios to address the differing needs of customers. Increasing numbers of brands are entering new segments, resulting in increased variety and growing potential consumer bases.

Their highly tech-driven economy and emphasis on innovation are giving rise to advanced vacuum evaporator systems in Korea. Sustainable energy and energy efficiency are not just slogan, but rather the keystone of global building practices that enhance Korea's competitiveness in the global sector.

FMI opines that the South Korea vacuum evaporators sales will grow at nearly 8.2% CAGR through 2025 to 2035.

Impellers of growth in a changing environment as companies adapt to changing economic dynamics and consumer preferences, they are finding opportunities to seize them. The focus on quality control, attention to detail, and precision that Japan is known for means that any vacuum evaporator produced in this country will be reliable and efficient.

However, the combination of advanced technologies and strict environmental regulations gives Japan an important segment presence. Innovation and industry expansion are further propelled through collaborations between industry and academia.

FMI opines that the Japan vacuum evaporators sales will grow at nearly 6.5% CAGR through 2025 to 2035.

China is one of the key geographies for the vacuum evaporators, attracting both domestic and international manufacturers. Due to continuous investment in technology and a strong supply chain, the industry is expected to account for one of the fastest-growing growth rates in the region.

As China emphasizes industrial modernization and the need for environmental sustainability, the use of advanced vacuum evaporator systems is gaining traction. When combined with favorable government policies and initiatives that support this sector, the segment becomes even more attractive to stakeholders and creates lucrative opportunities.

FMI opines that the China vacuum evaporators sales will grow at nearly 9.0% CAGR through 2025 to 2035.

Australia and New Zealand's focus on environmental sustainability and technological intervention drives the market for evaporators and vacuums. The strong industrial presence in these countries necessitates innovative solutions for industrial wastewater treatment and resource recovery, thereby driving the demand for vacuum evaporators.

Stress on compliance with stringent environmental and safety regulations, as well as the demand for energy-efficient technologies, is fostering industry growth. Partnerships with global manufacturers and investments in research and development enhance the local industry's capabilities for modern vacuum evaporator designs.

FMI opines that the Australia and New Zealand vacuum evaporators sales will grow at nearly 6.5% CAGR through 2025 to 2035.

Major players in the vacuum evaporators industry are embracing a combination of innovation, strategic alliances, geographic expansion, and competitive pricing to improve their industry shares. As demand for energy-efficient and sustainable technologies increases, top players are spending on R&D to improve evaporation efficiency and lower operating expenses. Customization and modular system designs are also on the rise, enabling companies to serve varied industry requirements, ranging from wastewater treatment to food & beverage processing.

Strategic acquisitions and partnerships are becoming essential to expand technological capabilities and geographical reach. Companies such as GEA Group, Veolia, and SPX Flow are collaborating with regional distributors to grow their foothold in the developing sectors. Expansion plans include opening new manufacturing sites and service facilities in high-growth sectors, including China, India, and Southeast Asia.

Veolia

Suez

Condorchem Envitech

ENCON Evaporators

3M

Other Players (Combined)

The vacuum evaporators industry lies in the industrial equipment and environmental technology segment broadly and is connected closely with segments. Industry growth depends on industrialization, environmental rules and regulations, infrastructure, and the economic cycle of different sectors.

General rises in GDP across global landscape, industry production levels as well as capital spending (capex), which makes significant contributions to demand. With governments globally cracking down on environmental controls in terms of wastewater disposal and industrial emissions, companies are turning towards vacuum evaporators as environmentally friendly solutions to waste minimization and water reuse.

Inflation and volatility in raw material prices (e.g., stainless steel, energy prices) also influence capital investment choices. Beneficial government policies, subsidies, and sustainability programs, primarily in Europe and North America, favor the industry. As the circular economy becomes more popular, businesses are looking for better evaporators that make better use of energy, produce fewer waste products, and recycle useful byproducts.

The landscape for vacuum evaporators offers substantial growth prospects, led by the growing demand for industrial wastewater treatment technologies. Global tightening of environmental regulations and efforts to adopt zero liquid discharge (ZLD) systems are forcing industries to invest in sophisticated evaporation technologies. China, India, and Southeast Asia provide sectors with strong growth opportunities through fast-paced industrialization and government initiatives to promote reuse of wastewater.

New players require a specific strategy to build momentum in the sector and contend against required competitors. New companies can concentrate on specialized niches, like recycling batteries, processing food, or small-scale evaporators for plants with limited space. Modular, customizable products will also offer benefits, especially within sectors like South Korea and Japan, where companies need high-performance and custom solutions. By distinguishing themselves based on innovation, service quality, and local orientation, new players can gain a solid foundation in this dynamic sector.

Vacuum evaporators find extensive applications in wastewater treatment, food & beverage processing, pharmaceuticals, chemicals, electronics, and power generation for effective liquid concentration and waste reduction are the primary industries that employ vacuum evaporators.

These systems enable industries to save water, recover valuable byproducts, and reduce liquid waste disposal, aiding zero liquid discharge (ZLD) programs and environmental regulations.

The main drivers are energy efficiency, operational expenses, regulatory compliance, available space, and industry process needs. Higher levels of automation and IoT integration are also increasing adoption.

Heavy demand is seen in Asia-Pacific, Europe, and North America, specifically in the USA, China, Germany, and Japan, where process efficiency and treatment of industrial wastewater is a major priority.

Advancements come in the form of mechanical vapor recompression (MVR), heat pump evaporation, and intelligent monitoring systems, enhancing energy savings, process control, and system life in general.

Thermal, Heat Pump, and Mechanical Vapor Recompression

Wastewater Treatment, Product Processing, and Other

Automotive, Chemical & Petrochemical, Electronics & Semiconductor, Energy & Power, Food & Beverage, Pharmaceutical, and Others

North America, Latin America, Western Europe, Eastern Europe, Russia and Belarus, Balkan and Baltic Countries, Central Asia, East Asia, South Asia and Pacific, and Middle East and Africa

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.