The USA supplier quality management applications market is expected to grow from USD 1,449.6 million in 2020, and estimate around USD 4,084.3 million by 2025 and it will reach up to USD 12,184.8 million by end of 2035, recording a CAGR of 11.6% from the period 2025 to 2035.

The market is driven by factors such as changing emphasis on regulatory compliance, rising adoption of cloud-based quality management solutions, and increasing complexity of supply chains across various industries such as automotive, aerospace & defense, and healthcare.

| Attributes | Values |

|---|---|

| Estimated USA Industry Size in 2025 | USD 4,084.3 million |

| Projected USA Industry Size in 2035 | USD 12,184.8 million |

| Value-based CAGR from 2025 to 2035 | 11.6% |

For instance, strict supplier quality rules laid down by organizations like the FDA, ISO, and NHTSA are promoting the implementation of SQM applications, as the integration of AI and automation in the quality control process. Furthermore, multi-cloud deployment models are now commonplace, supporting real-time supplier performance insights and compliance monitoring.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

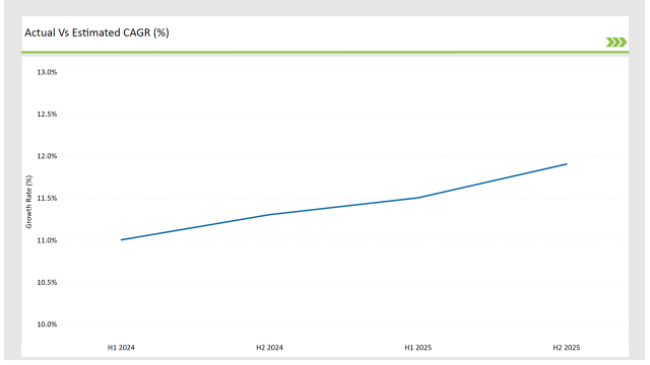

The table below highlights the CAGR trends over six-month intervals, offering insights into market growth momentum.

| Particular | Value CAGR |

|---|---|

| H1, 2024 | 11.0% |

| H2, 2024 | 11.3% |

| H1, 2025 | 11.5% |

| H2, 2025 | 11.9% |

(H1 signifies January to June, while H2 represents July to December analysis.)

The steady increase in CAGR indicates accelerating adoption driven by digital transformation, AI-based quality control, and increased regulatory pressure.

| Date | Development / M&A Activity & Details |

|---|---|

| Jan-2025 | SAP launched an AI-driven supplier quality analytics tool for real-time defect tracking. |

| Oct-2024 | Oracle acquired a cloud-based compliance platform to enhance supplier risk management. |

| Mar-2024 | FDA updated supplier quality compliance guidelines, increasing automation requirements. |

| Sep-2024 | Dassault Systèmes partnered with aerospace manufacturers for AI-powered supply chain quality control. |

| Dec-2023 | IBM introduced blockchain-based supplier quality monitoring for enhanced traceability. |

Leading vendors are investing in AI-driven automation, blockchain for traceability, and multi-cloud supplier quality solutions to improve compliance and operational efficiency.

Automation Enhances Supplier Quality Compliance

Sectors like automotive and aerospace are rapidly embedding AI-infused supplier quality management within their processes to strengthen compliance and reduce risk. Most of the classic supplier quality evaluations are based on manual processes that are vulnerable to human errors, inefficiency, and inconsistencies.

AI-driven analytics transforms this space with the automation of data collection, pattern recognition, and anomaly detection, reducing the chances of blocks in supplied components. For example, machine learning algorithms can analyze historical data to identify trends in supplier performance, predict potential quality issues, and recommend corrective actions- all in real-time.

In addition, AI-based quality management systems enable automated supplier audits, verifying compliance with industry standards and minimizing administrative effort. Customer satisfaction is improved due to better transparency in supplier performance ensuring the materials are not defective and regulatory compliance is adhered to.

With the ever-growing demands for quality and compliance across various industries, AI support systems for supplier quality management are emerging as a competitive essential, allowing manufacturers to ensure high standards while maintaining operational efficiency.

Cloud-Based Supplier Quality Solutions Gain Momentum

Cloud-based supplier quality solutions are increasingly being adopted by different industries because of their ability to provide real-time quality monitoring, scalability, and enhanced data security. Thanks to the complexities of traditional on-premise quality management systems, they often lack the flexibility required to promote collaboration between global suppliers and manufacturers.

Inevitably, cloud-based solutions mean your data is centralized and allows anyone from Supplier to Quality Manager to have visibility of compliance metrics, non-conformances and corrective action in real time. They also provide automated workflows, advanced analytics, and AI-powered insights that streamline supplier performance evaluations, enabling risk mitigation for potential failures in quality.

In addition, smarter cybersecurity solutions, including encryption and multi-factor authentication, safeguard data and regulatory adherence. As a response to this trend, organizations are turning to cloud-native solutions such as supplier quality management to help them back in control of their compliance requirements.

Regulatory Authorities Push for Digital Compliance

Regulatory agencies like FDA, ISO & AS9100 have strict compliance requirements, forcing the industries to adopt experiential digital supplier quality management solutions. For instance, compliance is a critical issue in pharmaceuticals, aerospace, food manufacturing, etc. where non-compliance often results in penalties, recalls, and loss of reputation.

The industries still use traditional paper documentation and manual audits, which are inefficient and inaccurate and increase the chances of non-conformity. Digital solutions also provide automated tracking, real-time compliance monitoring, and instant reporting capabilities that reduce the administrative burden on manufacturers and suppliers.

Technologies like AI and blockchain take compliance to the next level by ensuring accurate documentation and tracking across the entire supply chain. Moreover, organizations can remain cognizant of ever-evolving regulatory mechanisms through integrated digital platforms, allowing for proactive staying ahead of compliance, rather than purely reactive risk mitigation.

As regulatory bodies seek to be more transparent and accountable, companies need to adopt digital supplier quality management systems for long-term operational success.

Blockchain Integration for Supplier Transparency

Blockchain is an innovation with the potential to transform supplier quality management like never before through transparency, security, and traceability. In these cases, especially for regulated industries like pharmaceuticals, aerospace, and automotive, quality standards must be met during supply chain processes to protect product integrity and regulatory compliance.

It provides a distributed and tamper-proof table on which quality records regarding suppliers, their certifications, and compliance data get stored and validated. This reduces risks, such as data tampering, fraud, and disparity in reporting. Using blockchain, you can create an auditable record of each supplier on a distributed ledger and tracking materials from procurement to production in real time.

In this way, compliance verification can be performed in a fully automated fashion through smart contracts, minimizing human intervention and allowing only certified suppliers to join the supply chain. Blockchain-based supplier quality management solutions are becoming a game changer in this aspect with increasing pressure on industries to enhance supply chain integrity and quality assurance, it has now become possible for organizations to build trust and help mitigate risks.

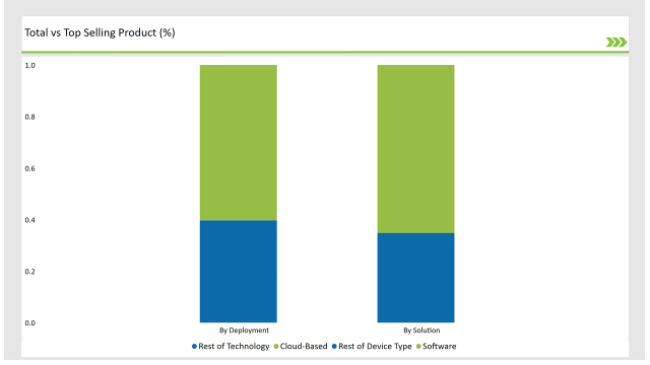

| Solution | Market Share (2025) |

|---|---|

| Software | 65.2% |

| Services | 34.8% |

Software solutions dominate due to their ability to automate quality checks, compliance tracking, and risk assessment. Services such as consulting and implementation support complement software adoption.

| Deployment Type | Market Share (2025) |

|---|---|

| Cloud-Based | 60.3% |

| On-Premises | 39.7% |

Cloud-based solutions are gaining a lot of traction due to the cost factor, flexibility and assist for real-time analytics, however, on-premises deployment is still significant for industries that require high regulation, such as aerospace & defense.

Check Free Sample Report & Save 40%!

Select your niche segments and personalize your insights for smart savings. Cut costs now!

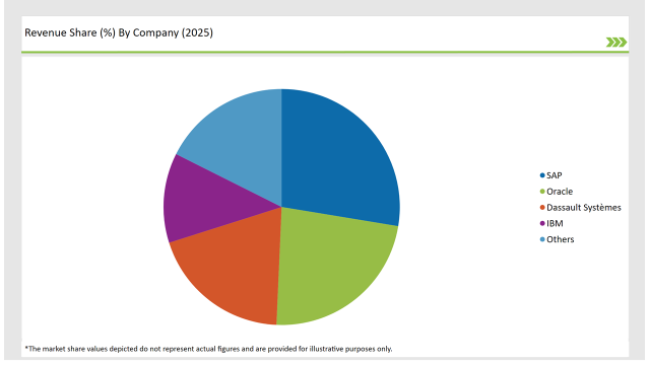

Top players use AI, cloud, and blockchain technologies to differentiate their supplier quality solutions. Some of the main vendors in this market are SAP, Oracle, Dassault Systèmes, IBM, and PTC.

| Vendors | Market Share (2025) |

|---|---|

| SAP | 27.6% |

| Oracle | 23.1% |

| Dassault Systèmes | 19.4% |

| IBM | 12.3% |

| Others | 17.6% |

Software and Services. Software dominates due to automation, compliance, and analytics capabilities.

Cloud-Based and On-Premises. Cloud adoption is accelerating due to flexibility and cost-efficiency.

Automotive, Aerospace & Defense, Electronics & Semiconductors, Healthcare, Food & Beverage, and Others. Automotive and aerospace lead adoption.

The USA Supplier Quality Management Applications Market will grow at a CAGR of 11.6% from 2025 to 2035.

By 2035, the industry is projected to reach USD 12,184.8 million.

Regulatory compliance mandates, AI-driven automation, and increased cloud adoption.

The Software segment (65.2%) holds the highest share due to automation and compliance requirements.

Leading players include SAP, Oracle, Dassault Systèmes, IBM, and PTC.

| Estimated Size, 2025 | USD 14,061.6 million |

| Projected Size, 2035 | USD 38,081.4 million |

| Value-based CAGR (2025 to 2035) | 10.5% CAGR |

Explore Vertical Solution Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.