The UK Supplier Quality Management (SQM) applications market is projected to reach USD 1,286.7 million by 2025 and USD 3,329.7 million by 2035, growing at a CAGR of 10.0% during the forecast period. Factors such as stringent regulatory compliance, increasing complexity in supply chains, adoption of cloud-based SQM solutions, and the rise of AI-driven automation are driving market expansion.

| Attributes | Values |

|---|---|

| Estimated UK Industry Size 2025 | USD 1,286.7 million |

| Projected UK Industry Size 2035 | USD 3,329.7 million |

| Value-based CAGR from 2025 to 2035 | 10.0% |

As global supply chains become more complex, manufacturers need tighter regulations, real-time quality monitoring and automated supplier risk management. Firms are selecting AI-based compliance solutions to minimize manual errors, increase audit precision, and potentially identify quality risks.

Predictive analytics powered by AI offers insights to help prevent supplier disruptions and ensure compliance with regulations. At the same time, block chain technology is also revolutionizing supplier traceability by providing an immutable, shareable, and transparent record of transactions, thus eliminating fraud opportunities.

The emergence of multi-cloud and API-driven quality management platforms also drives innovation by facilitating the integration of existing enterprise systems. Source: Available only through request These platforms provide increased scalability, automated compliance workflows, and improved supplier collaboration.

With increased regulatory pressures and ever greater supply chain risks, companies are adopting digital transformation to achieve better efficiency, de-risking, and long-term sustainability.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

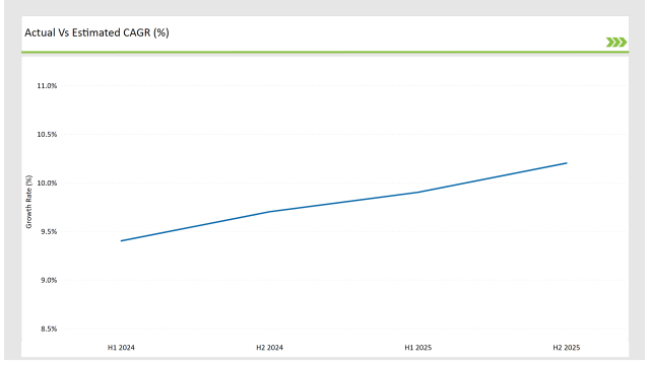

The following table outlines the CAGR trends over six-month intervals, reflecting growth dynamics in the market.

| Particulars | Value CAGR |

|---|---|

| H1, 2024 | 9.4% |

| H2, 2024 | 9.7% |

| H1, 2025 | 9.9% |

| H2, 2025 | 10.2% |

(H1 signifies January to June, while H2 represents July to December analysis.)

Market momentum is driven by the digital transformation of supplier quality monitoring, regulatory compliance mandates, and cloud-based analytics adoption. The increase in growth from 9.4% in H1 2024 to 10.2% in H2 2025 highlights the sector’s rapid adaptation to next-gen quality assurance tools.

| Date | Development/M&A Activity & Details |

|---|---|

| Jan-2025 | SAP launched an AI-powered Supplier Quality Management suite for manufacturers. |

| Oct-2024 | IBM acquired a cloud-based compliance platform to enhance supplier risk management. |

| Mar-2024 | The UK Government revised supplier quality regulations, pushing for automated compliance reporting. |

| Sep-2024 | Siemens partnered with automotive firms to integrate AI in supply chain quality analytics. |

| Dec-2023 | Oracle introduced blockchain-based supplier audit tracking for enhanced security. |

Leading technology vendors are investing in AI automation, cloud-based platforms, and blockchain solutions to streamline compliance and enhance supplier collaboration.

AI & Automation Enhance Supplier Quality Compliance

AI-driven supplier quality management (SQM) solutions are gaining wide recognition and adoption among industries for enhanced accuracy, lesser manual errors, and streamlining of compliance processes. AI-enabled analytics offer real-time tracking of supplier performance, which helps detect quality vulnerabilities or deviations early on itself.

By enabling automated supplier audits and predictive analytics, companies can be proactive in tackling issues before they become critical, which can save money by reducing recalls or fees for compliance failures. Historical high volumes of supplier data are analysed by machine learning algorithms to identify patterns, and suggest corrective actions, facilitating continuous improvement.

Moreover, AI-based document verification streamlines the compliance process by reducing human involvement, thereby optimizing efficiency. Implementing AI-SQM will enable enterprises to uphold superior standards in quality, hold suppliers accountable for breaches, comply with ever-evolving regulations or requirements, and improve overall supply chain resilience and operational efficiency.

Cloud-Based SQM Platforms Gain Traction

Cloud-based SQM (supplier quality management) platforms have become a need for companies looking to improve scalability, analytics, and supplier monitoring remotely. These solutions collect quality data in one place, enabling manufacturers and suppliers to work together across global supply chains.

Cloud SQM software allows for seamless workflows, decreasing administrative load and fast-tracking the corrective action process. Real-time analytics give instant insights on suppliers' performances so that enterprises can identify quality issues early and take proactive measures.

Other noteworthy features include advanced data security options, which include things such as encryption and access control to help ensure data integrity as well as compliance with regulations. Moreover, cloud solutions also lower the expenses of the IT infrastructure and enhance the accessibility of the system that allows remote auditing and compliance tracking.

Cloud-based SQM solutions provide a flexible, efficient, and cost-effective way to maintain supplier quality and compliance as supply chains become increasingly complex.

Regulatory Push for Digital Supplier Quality Monitoring

Digital transformation in supplier quality management has been driven by governments and industry regulators, including the UK government, mandating greater transparency and efficiency. Businesses must face more stringent regulations including adopting a new audit system where automated audits with electronic compliance reporting or digitally tracked systems.

These actions reinforce organizations with real-time transparency into the performance of suppliers and checks at quality standards. Digital monitoring solutions aid in compliance documentation, cutting down on do-it-yourself errors as well as administrative overheads.

With AI and blockchain, traceability and compliance are further secured, reducing the chances of fraud or unethical corporate behaviour. With the power of digital supplier quality management systems, companies can optimize their approach to compliance while meeting the ever-changing landscape of regulatory requirements, mitigating risks and achieving compliance with industry standards seamlessly, thus enhancing supply chain integrity and operational resilience.

Block chain Integration for Supplier Traceability

Blockchain technology sets a new standard for quality coordination through supplier traceability. Two Use Cases for Blockchain in Supplier Compliance Security- Blockchain is used in companies to verify supplier credentials, track audits, and ensure compliance security.

The Peer to Peer Transactions: Each transaction is recorded within an immutable ledger which cannot be modified, thereby eliminating data manipulation that leads to fraud risks. Smart contracts are used to automate compliance verification, allowing only authorized suppliers to participate in the supply chain.

One way blockchain can help streamline manufacturing is to improve traceability, as it allows producers to monitor materials and components in real time from source to production. While there are many use cases of blockchain, integrating it with supplier quality management strengthens data integrity, reduces the effort in audits, and establishes confidence across the stakeholders.

The complex nature of the supply chains allows blockchain to add an extra layer of accountability, thereby minimizing compliance risks and enhancing the quality assurance of suppliers.

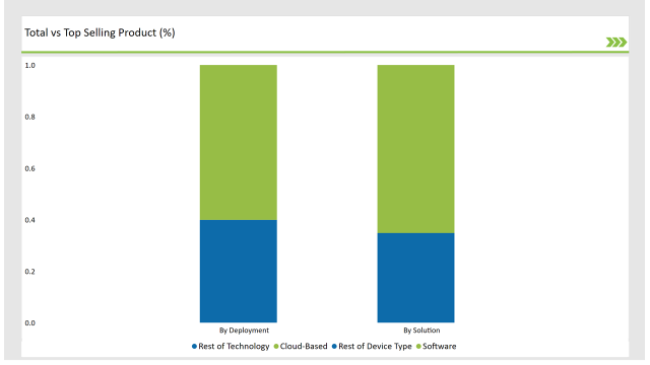

| Solution | Market Share (2025) |

|---|---|

| Software | 65.2% |

| Services | 34.8% |

Software dominates the SQM market due to its ability to automate compliance processes, integrate with enterprise IT, and enhance predictive analytics. The services segment is growing as demand for regulatory consulting and implementation support rises.

| Deployment Type | Market Share (2025) |

|---|---|

| Cloud-Based | 60.1% |

| On-Premises | 39.9% |

Cloud-based deployment leads due to its cost-effectiveness, real-time compliance tracking, and scalability. On-premises solutions remain relevant for large enterprises requiring data control and custom compliance workflows.

Check Free Sample Report & Save 40%!

Select your niche segments and personalize your insights for smart savings. Cut costs now!

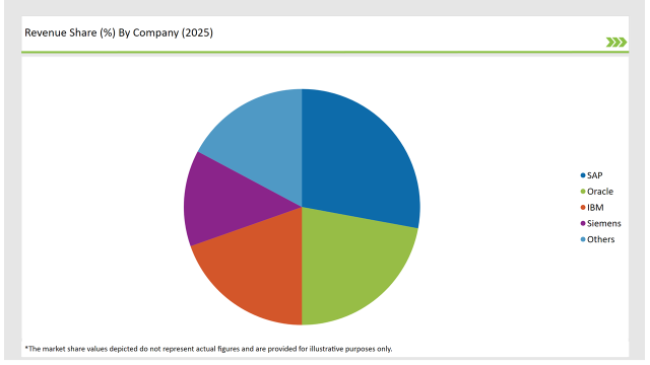

Leading technology providers are investing in AI, cloud-based platforms, and blockchain solutions to gain a competitive edge.

| Vendor | Market Share (2025) |

|---|---|

| SAP | 27.9% |

| Oracle | 22.1% |

| IBM | 19.6% |

| Siemens | 13.2% |

| Others | 17.2% |

Key players such as SAP, Oracle, IBM, and Siemens are leveraging automation, AI, and compliance analytics to differentiate their offerings.

Software & Services. Software dominates due to automation and compliance features.

Cloud-Based & On-Premises. Cloud adoption is accelerating due to scalability and efficiency.

Automotive, Aerospace & Defense, Electronics & Semiconductors, Healthcare, Food & Beverage, and Others. Automotive and Aerospace sectors are leading adopters.

The UK Supplier Quality Management Applications Market will grow at a CAGR of 10.0% from 2025 to 2035.

By 2035, the industry is projected to reach GBP 3,329.7 million.

Key drivers include regulatory compliance mandates, AI-driven automation, and cloud adoption.

The Software segment dominates at 65.2% due to automation and compliance features.

Leading players include SAP, Oracle, IBM, Siemens, and emerging tech-driven regulatory providers.

| Estimated Size, 2025 | USD 14,061.6 million |

| Projected Size, 2035 | USD 38,081.4 million |

| Value-based CAGR (2025 to 2035) | 10.5% CAGR |

Explore Vertical Solution Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.