The tube sealing machines industry is expected to grow at a significant rate, due to the increasing demand for efficient and effective sealing solutions across various industries. Sealing tubes is a critical step in many industries, including pharmaceuticals, cosmetics, food, and industrial applications, as it helps ensure product safety, prevents contamination, and extends shelf life.

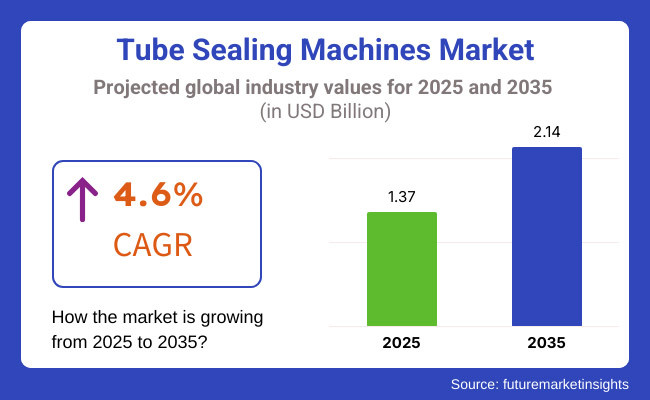

The industry is expected to reach USD 1.37 billion by 2025, indicating increasing adoption. It is estimated that the industry is projected to be USD 2.14 billion by 2035 and is to grow at a CAGR of 4.6% during the forecast period.

The increasing demand for high-speed sealing solutions, advancements in the automation of packaging machinery, and the focus on sustainable packaging solutions will drive the growth of the industry. Also, as businesses look for a more efficient and precise way of packaging their products, the availability of easy to use and multi-functional sealing machines is expected to increase.

The shift toward eco-friendly and biodegradable tube packaging is driving manufacturers to develop new sealing technologies. The industry in the Asia-Pacific region is expected to grow at a higher rate because of the rapid industrialization and the growing pharmaceutical and personal care industries. The next decade looks promising for the tube sealing machines industry, as manufacturers incorporate changing packaging trends and invest in automation to enhance production efficiency.

Explore FMI!

Book a free demo

The Tube Sealing Machines Market is expected to experience significant technological developments between 2020 and 2024. To improve the efficiency and precision of the sealing processes, manufacturers integrated automation and integrating automation and increasing the use of robotics.

There was also a shift towards eco-friendly packaging a movement towards eco-friendly packaging, with machines aligning with sustainable materials to meet environmental requirements. Also, there has been an increasing focus on customization and flexibility, enabling machines to accommodate various tube sizes and materials to meet different industry requirements. In addition, stringent regulations in industries such as pharmaceuticals and food, among others, are also expected to continue to drive the growth of advanced sealing technologies.

The market evolution will continue to develop from 2025 through 2035. The integration of AI and IoT is expected to revolutionize tube sealing machines, enabling real-time monitoring, predictive maintenance, reduced downtime, and enhanced productivity.

With a growing focus on sustainability, the demand for sustainable packaging solutions will drive innovations in machinery design to minimize material waste and energy consumption the shift toward customization is expected to accelerate, as machines become more adaptable to a variety of product types and fast-changing consumer needs. Adherence to changing global regulations will keep shaping machine components to ensure the safety and quality of products, in each field.

| Key Drivers | Key Restraints |

|---|---|

| Increasing demand for efficient and automated packaging solutions | High initial investment costs for advanced sealing machines |

| Growth in the pharmaceutical, cosmetics, and food industries | Maintenance and operational complexities |

| Rising adoption of sustainable and eco-friendly packaging materials | Limited availability of skilled labor for operating advanced machines |

| Advancements in AI and Industry 4.0 integration | Regulatory challenges and compliance requirements |

| Expansion of e-commerce and direct-to-consumer packaging trends | Variability in raw material prices affecting machine components |

| Increasing preference for user-friendly and high-speed sealing solutions | Competition from alternative packaging technologies |

Impact Assessment of Key Drivers

| Key Drivers | Impact |

|---|---|

| Increasing demand for efficient and automated packaging solutions | High |

| Growth in the pharmaceutical, cosmetics, and food industries | High |

| Rising adoption of sustainable and eco-friendly packaging materials | Medium |

| Advancements in AI and Industry 4.0 integration | High |

| Expansion of e-commerce and direct-to-consumer packaging trends | Medium |

| Increasing preference for user-friendly and high-speed sealing solutions | High |

Impact Assessment of Key Restraints

| Key Restraints | Impact |

|---|---|

| High initial investment costs for advanced sealing machines | High |

| Maintenance and operational complexities | Medium |

| Limited availability of skilled labor for operating advanced machines | Medium |

| Regulatory challenges and compliance requirements | High |

| Variability in raw material prices affecting machine components | Medium |

| Competition from alternative packaging technologies | Low |

From 2025 to 2035, plastic tube will remain the leading segment in the tube sealing machines market due to its cost-efficiency as well as versatility. The sealing technology is innovative, which will be implemented by the manufacturers to maintain the tube's closure tamper-proof and intact. The need for lightweight, flexible, and recyclable plastic tubes will continue to drive innovations in sealing methods, and sustainability will remain at the forefront.

The aluminium tube segment will observe steady growth as industries focus on durability and product protection. Such tubes will continue reining as the first choice for pharmaceuticals and cosmetics due to their properties of being impermeable to light, air and contaminants. Future Evolution of Tube Sealing Machines: Balancing Product Integrity and Eco-Friendly Demands.

Aluminium packaging is expected to drive tube sealing technology evolution to produce precise seals while preserving the integrity of the contents. The laminated tube segment will grow with brands looking for better aesthetics and functional benefits. These tubes are gaining ground in personal care and oral hygiene applications which require high-quality seals and longer shelf life. The demand for high-end product ranges and airtight and leak-proof packages will foster advanced sealing technologies.

Metal tubes will continue to be used in specialized and commercial sectors. Sectors with high demand for sturdy packaging will ensure continued demand for metal tubes, encouraging manufacturers to improve sealing machine features. As a result, the trend will move toward automated, high-speed sealing solutions to maximize efficiency, ideal for operation in high-production volume settings.

As industries adopt fully automated packaging lines, The market for automatic sealing machines the largest market share. Automatic sealing machines will be widely adopted due to the demand for increased production efficiency, lower labor costs, and uniform sealing quality. Industry 4.0 and AI-powered monitoring systems will help assure productivity, thus automated solutions will attract more significant and large-scale manufacturers.

The demand for semi-automatic sealing machines is expected to remain with small and medium-scale industries. Semi-automatic machines will remain in high demand among businesses in need of cost-effective but highly efficient sealing solutions. Their ability to work with various tube materials and larger tube sizes means this machine will remain a good option for companies with a mid-level production need.

As the personal care and pharmaceutical sectors continue to grow, it will contribute significantly to the growth of the cream segment in this industry. Increasing need for skincare, medicated creams, and beauty products will augment the demand for high accuracy sealing solutions to prevent product breaches and administer safety of the consumers. The gel segment will enjoy some uplift from increased demand in healthcare, personal-care and industrial applications.

Demand for contamination-free and airtight seals will compel manufacturers to come up with advanced sealing technologies that align with varying viscosity levels and packaging requirements. The ointment segment will see moderate growth owing to the rising demand for pharmaceutical and healthcare products.

In addition, high-performance sealing technologies with secure and tamper-proof features are going to be significant, and compliance with strict regulatory requirements will continue to be the priority. The shampoo segment will overlap, as the category adapts new formulations and formulates multiple package innovations in the beauty and personal care industry.

Tube sealing machines will be indispensable for leak-proof packaging for high-viscosity and semi-viscosity products that need to guarantee the brand name and consumer convenience. The toothpaste segment would create demand for sealing machines with higher efficiency. As global consumption of oral care products continues to increase, manufacturers will prioritize high-speed, fully automated sealing solutions to help meet production goals without sacrificing quality and hygiene standards.

Others will cover a range of niche applications, such as food and adhesives as well as specialty chemicals. Customized sealing solutions will become the need of the hour leading to manufacturers designing versatile tube sealing machines in order to meet the specific industry requirements whilst enabling maximum efficiency.

Pharmaceuticals, cosmetics, and food packaging needs are poised to drive steady growth in the USA tube sealing machine market. Automation, sustainability, and energy-efficient machines will redefine the industry. More stringent FDA guidelines will also drive manufacturers to implement more advanced sealing technologies.

The growth in e-commerce will lead to greater demand for durable, tamper-proof packaging. Innovation will be powered by domestic manufacturing and R&D investments. Labor shortages and high production costs, however, could prove difficult. The sector is set for consolidation as big players acquire smaller companies to boost technology and industry access. Growth will be slow but steady.

Demand for sustainable packaging and growing production in the pharmaceutical industry will make Canada’s landscape thrive. Government policies promoting sustainable practices will lead to the adoption of recyclable and biodegradable tubes, fueling innovation in sealing technologies. The market growth is further driven by increasing personal care and cosmetics consumption.

High machinery costs and dependence on imports, however, can slow adoption rates. Packaging with convenience and long-shelf-life in mind, the food industry’s new focus, will create further opportunities. The gradual adoption of smart and automated sealing machines, particularly among large-scale manufacturers, will also pave the way for technological advancements. Growth will be steady but slower compared to the USA market.

Post-Brexit trade policies, sustainability regulations, and automation trends will shape the UK tube sealing machine landscape. The demand will be driven by the cosmetics and pharmaceutical industries, particularly for precision sealing technologies. The expanding range of private label personal care products will drive demand for cost-effective sealing solutions.

Tighter environmental legislation will drive the transition to recyclable materials, and push for machinery upgrades. Pandemic-induced hesitancy combined with rising labor costs and skills shortages may drive acceleration in automation adoption. The imports from Europe will continue but domestic innovation in sealing technology can allow local production to be stronger. We anticipate moderate but consistent growth in the landscape throughout the decade.

France’s landscape will grow steadily, backed by the country’s strong cosmetics and pharmaceutical industries. Sustainable packaging regulations will also drive manufacturers towards recyclable/eco-friendly tube materials, demanding sophisticated sealing solutions.

High Speed and Automated tube sealing machines will be sought after by manufacturers who want to improve efficiency. The requirement for precision sealing to maintain product integrity will drive innovation in the luxury personal care segment. Government incentives to replace and automate them may also help drive investment in new machines.

Germany's leadership in industrial automation and engineering will drive growth in the tube sealing machines market. The country’s robust pharmaceuticals and automotive lubricant industries will be major drivers. Sealing machines that consume less energy, and recyclable materials will be promoted by sustainability regulations.

The participation of top machine vendors in these forces will lead to technological advancements like AI-based automation and predictive maintenance. Increasing labor costs could speed up automation adoption The demand for globally compliant sealing technologies will be driven by Germany's export-oriented economy. The landscape will see consistent growth, driven by a demand for high-performance, precision seals for a variety of industrial applications.

Technological advancements, booming cosmetics export, and rising pharmaceutical production will shape South Korea’s tube sealing machine landscape. With the country launching into automation and smart factories, AI integrated sealing is sure to garner interest in the country.

The global explosion of K-beauty will demand efficient and precise tube sealing. The government’s movement for green packaging will promote the development of final sealing solutions. But Japanese and Chinese producers could keep pressure on home-grown ones. The forecast calls for a strong, high-end growth segment, with South Korea already well-versed in advanced machinery and high-quality packaging and manufacturing solutions.

Automated factories, a strong pharmaceutical industry, and cosmetic packaging will drive Japan’s landscape. This will create the need for high-speed, ultra-accurate sealing machines in the country’s focus on precision engineering. Sustainability initiatives will drive the move toward biodegradable tubes, which will in turn necessitate new seal technologies.

An aging population will increase demand for pharmaceutical packaging, and demand for premium cosmetics will continue to drive high-end machine sales. Japan’s manufacturers are export-oriented, so will emphasize precision and durability. But with a decreasing labor pool and increased operational cost, companies may be forced to farm out production. Growth will be consistent, centered on advanced automation and energy-efficient solutions.

The massive manufacturing base and increasing automation in the packaging industry of the country will drive China landscape. The government initiatives which promote smart manufacturing would augment the demand for sealing machines that are powered by AI and IoT. A quick expansion of the cosmetics, pharmaceuticals, and food industries will help to maintain demand.

They will be able to capture the international landscape, due to low-cost production and low retail pricing. Companies will be pushed towards sustainable packaging solutions due to sustainability regulations. But rising labor costs and regulatory challenges could weigh on growth. Chinese firms will export sealing and invest in high-tech sealing technology, and the landscape will grow rapidly.

The tube sealing machine sector in India will grow significantly due to increasing demand for pharmaceutical, food, and personal care packaging. Increased local production and emphasis on technology through government-backed initiatives such as “Make in India” We are investing in new sealing solutions here as the future is sustainable packaging.

The demand for high-end cosmetic packaging will be driven by growing disposable incomes and urbanization. Nonetheless, uneven regulatory enforcement and infrastructure deficiencies may hinder the pace of change. The market will expand rapidly in India, with domestic and international players investing in automation and efficiency improvements to meet the growing consumer demand.

The tube sealing machine sector is highly consolidated because a few Tier 1 players control 90% of the industry share. Leading companies dominate the industry, setting trends in innovation, automation, and pricing. Their stronghold creates high entry barriers, making it difficult for smaller competitors to gain traction.

These major players drive technological advancements and efficiency improvements, shaping the sector’s direction. While smaller firms operate in niche segments, they hold minimal influence. The sector remains competitive at the top, with industry leaders continuously expanding their reach and strengthening their sector positions through acquisitions and advanced manufacturing capabilities.

Leading tube sealing machine manufacturers have concentrated on innovation and strategic acquisitions in 2024. The rising supply of environmentally friendly options has also led to the development of sustainable packaging solutions, with a strong focus on overrun capabilities and efficiency that has contributed to the new models of packaging by companies like Tetra Pak and Multivac.

However, the increasing automation observed over the past few years has seen KHS GmbH and Praxair Technology Inc. bolstering their technological capabilities to provide more automated and more accurate sealing solutions. New startups have focused their efforts on implementing smart technologies in their solutions. Industries have been focusing on transitioning to smart manufacturing, and as such, companies such as Omron Corporation and Schneider Electric have made significant investments in IoT-based systems to automate processes.

Startups are focusing on solutions that address changing packaging industry requirements of a packaging industry. The shape of the sector has also been significantly influenced by mergers and acquisitions. Interestingly, such consolidation efforts, like Aetna Group acquiring PackTech, are reminiscent of how companies merge to widen their product ranges and access new sectors, affording them greater market influence.

The increasing demand for automated, high-speed, and sustainable packaging solutions in industries like pharmaceuticals, cosmetics, and food is driving sector growth.

Automation enhances efficiency, reduces labor costs, and ensures precise sealing, making it a key focus for manufacturers investing in Industry 4.0 and AI-driven solutions.

Asia-Pacific, particularly China and India, is expected to experience rapid growth due to industrial expansion, rising pharmaceutical production, and increasing automation.

Manufacturers are focusing on eco-friendly packaging, leading to innovations in sealing technologies that reduce material waste and support the use of biodegradable tubes.

Plastic Tube, Aluminum Tube, Laminated Tube, and Metal Tube

Automatic and Semi-automatic

Cream, Gel, Ointment, Shampoo, Toothpaste, and Others

North America, Latin America, Europe, Asia Pacific, and Middle East & Africa (MEA)

BOPP Film Market Analysis by Thickness, Packaging Format, and End-use Industry Through 2025 to 2035

Korea Tape Dispenser Market Analysis by Material, Product Type, Technology, End Use, and Region through 2025 to 2035

Medical Transport Box Market Trend Analysis Based on Material, Capacity, End-User and Regions 2025 to 2035

Japan Heavy-duty Corrugated Packaging Market Analysis based on Product Type, Board type, Capacity, End use and City through 2025 to 2035

Corrugated Board Market Analysis by Material and Application Through 2035

Waterproof Packaging Market Trends - Demand & Industry Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.