Hygiene, personal care, and commercial paper product manufacturers are demanding efficient, high-speed, and precision-driven solutions from the tissue paper unwinding machine industry. Companies are focusing on automation, sustainability, and energy efficiency to increase productivity and reduce operational costs.

As demand for soft, durable, and eco-friendly tissue products increases, manufacturers upgrade their unwinding machines to accommodate advanced materials and improve production efficiency. There is also a push toward recyclable and biodegradable paper products that is driving innovation throughout the industry.

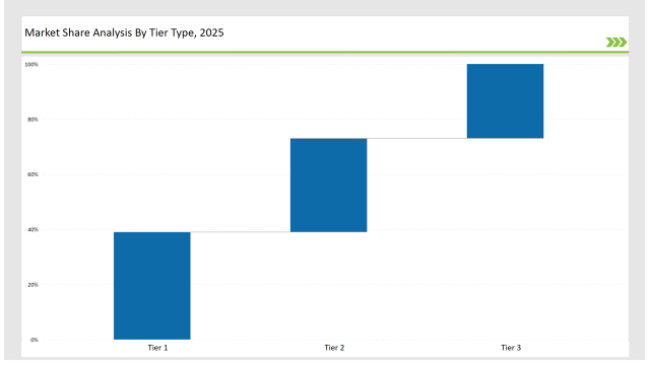

The Tier 1 players, such as Andritz AG, Valmet, and Fabio Perini, dominate the market share with 39%. These companies are leveraging cutting-edge automation, precision unwinding technology, and strong global networks.

Tier 2 companies, including BW Papersystems, Gambini, and Futura SpA, hold 34% of the market by offering customizable, high-speed, and cost-effective unwinding solutions tailored for small and mid-sized manufacturers.

Tier 3 consists of regional and niche manufacturers specializing in compact, energy-efficient, and industry-specific tissue paper unwinding machines, holding 27% of the market. These players focus on localized service, specialized unwinding solutions, and emerging paper technologies.

Explore FMI!

Book a free demo

Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Andritz AG, Valmet, Fabio Perini) | 18% |

| Rest of Top 5 (BW Papersystems, Gambini) | 13% |

| Next 5 of Top 10 (Futura SpA, Körber, Dechangyu, Baosuo Paper, A.Celli) | 8% |

The tissue paper unwinding machine market serves industries that demand high-speed, energy-efficient, and precision-based solutions to handle tissue, napkin, and hygiene paper production. As brands emphasize product softness, strength, and sustainability, demand for advanced unwinding technology continues to grow.

Manufacturers are advancing efficiency, precision, and sustainability in tissue paper unwinding machines.

The tissue paper unwinding machine industry is undergoing a transformation driven by sustainability and automation. Leading manufacturers are developing AI-powered monitoring systems, reducing machine energy consumption, and integrating recyclable paper-friendly mechanisms. The shift towards biodegradable and FSC-certified materials is also prompting upgrades in machine adaptability. Brands are investing in predictive maintenance and smart unwinding technologies to enhance performance and reduce downtime.

Year-on-Year Leaders

Technology suppliers should focus on automation, precision engineering, and energy-efficient unwinding solutions to meet evolving market demands. Partnering with global tissue manufacturers will accelerate adoption and technological advancements.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Andritz AG, Valmet, Fabio Perini |

| Tier 2 | BW Papersystems, Gambini |

| Tier 3 | Futura SpA, Körber, Dechangyu, Baosuo Paper, A.Celli |

Leading manufacturers are integrating automation, enhancing material adaptability, and optimizing energy efficiency to meet increasing industry demands.

| Manufacturer | Latest Developments |

|---|---|

| Andritz AG | Launched high-speed AI-enabled unwinding machines in March 2024. |

| Valmet | Developed modular, low-energy unwinding systems in April 2024. |

| Fabio Perini | Introduced fully automated, low-waste tissue unwinding machines in June 2024. |

| BW Papersystems | Strengthened commercial-grade high-speed unwinding technology in July 2024. |

| Gambini | Expanded eco-friendly, energy-efficient machine designs in August 2024. |

| Futura SpA | Released compact, AI-optimized tissue unwinding machines in May 2024. |

| Körber | Focused on smart monitoring and digital tracking features in September 2024. |

| Dechangyu | Innovated in ultra-fast, recyclable-material unwinding systems in October 2024. |

The competitive landscape in the tissue paper unwinding machine market is evolving as key players prioritize automation, sustainability, and digital integration to maintain strong market positions.

Manufacturers will integrate AI-powered diagnostics and predictive maintenance to optimize efficiency. The demand for sustainable paper production will drive innovations in energy-efficient and biodegradable-friendly unwinding machines. Smart packaging solutions, including IoT-enabled monitoring and automated material adjustments, will enhance production accuracy. As global tissue consumption grows, high-speed and modular unwinding machines will become critical for meeting industry demand while maintaining cost-effective operations.

Leading players include Andritz AG, Valmet, Fabio Perini, BW Papersystems, and Gambini.

The top 3 players collectively control 18% of the global market.

The market shows medium concentration, with top players holding 39%.

Key drivers include automation, energy efficiency, and sustainable material compatibility.

Pan Liner Market Analysis by Polyethylene (PE), Nylon, Polypropylene, Polyester, Polytetrafluoroethylene (PTFE) and Biodegradable Plastics Through 2035

Packaging Films Market Analysis by Product Type, Material Type and End Use Through 2035

Magnetic Closure Boxes Market Trends - Growth & Demand 2025 to 2035

Neoprene Coffee Sleeves Market Growth - Demand & Forecast 2025 to 2035

Mailer Boxes Market Growth – Demand & Forecast 2025 to 2035

Metal Aerosol Packaging Market Growth - Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.