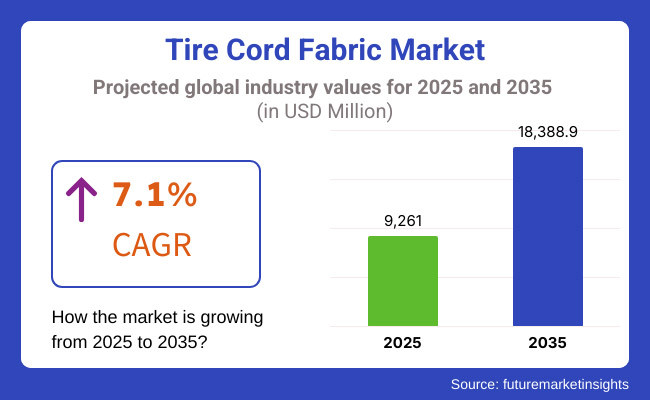

The global Tire Cord Fabric Market is set to grow significantly, projected to reach USD 18,388.9 million by 2035 from USD 9,261.0 million in 2025, growing at a 7.1% CAGR. This growth is fueled by the rising demand for high-performance tires, innovations in tire technologies, and the expanding automotive and electric vehicle (EV) markets.

Development of transport sector and increase in global automobile production are expected to directly influence the expanding Tire Cord Fabric Market. Conversely, tire manufacturers are zeroing in on new reinforcing materials for enhanced durability, strength and fuel economy.

Increasing penetration of radial tires especially in the commercial vehicles, also is boosting the market. The textile industry is undergoing a revolution with fabric construction transitioning from aramid to nylon to polyester fiber.

Additionally, rising awareness regarding sustainability and stringent policies across the globe for the promotion of green and high-performance tires are forcing the manufacturers to design in compatible and energy-efficient materials.

The demand that further received a boost last more than one in depth with more selection of electric vehicles come into light as these vehicles materials require such which could be lightweight and sturdy in quality to make the efficiency and battery life last longer

Along with the ever-growing automotive technology along with increased production of vehicles is expected to create numerous opportunities for the Tire Cord Fabric Market over the next couple of decades.

Market opportunities will favor businesses that invest in high-performance materials, sustainable manufacturing practices, and emerging automotive trends. With the automotive industry moving towards green and high-tech solutions, the demand for tire cord fabrics is likely to continue growing.

Nylon and polyesters are the most popular materials, given their price, durability, and high tensile strength among material types. The new small, flat fabrics are joined by other new designs being developed, such as aramid and hybrid fabrics, which are emerging as high-performance and specialty tire materials, especially in the aviation and motorsport sectors.

Passenger vehicles are still the largest application sector; however, demand for commercial and off-road vehicles is projected to grow drastically because of growing industrial and agricultural activities.

Explore FMI!

Book a free demo

Various factors such as robustness of the automotive sector in the region, growing demand for fuel-efficient and low-weight tires, and strict regulatory frameworks encouraging sustainable vehicle components drive the Tire Cord Fabric Market in North America. Key contributors include the United States and Canada, which heavily invest in experimental development of advanced materials.

The increasing adoption of electric and autonomous vehicles is also prompting innovations in tire technology. Moreover, the fact that major automobile manufacturers and tire companies operate in the region also creates a positive environment for market growth. That said, manufacturers must deal with supply chain disruptions and volatility in raw material prices.

Europe continues to be an important region for tire cord fabric in terms of volume, especially with the high volume of green tire materials and high-performance tire materials. Tight CO2 emission rules have compelled manufacturers to indulge in sustainable new-age innovations. Germany, France, and Italy lead in developing lightweight, durable, and high-strength (thermoplastic) tire reinforcements.

Moreover, the accelerating transition towards advanced tire technologies is driven by the growing electric vehicles demand across the region. There challenges posed by the rising environmental pressure is also resulting in research into tire materials being biodegradable and recyclable, opening up new avenues for regional market player’s intent on complying with the sustainability targets of the region.

In Asia-Pacific, the rapidly expanding automotive industry in China, India, and Japan are expected to make this region the most lucrative market for tire cord fabric.

Market growth is primarily driven by increasing disposable income, urbanization, and robust government support for domestic vehicle production. The increasing demand of radial tires is also contributing towards the reinforcement fabrics market in the region. Several big tire manufacturers are also setting up plants locally to meet growing demand in the region. Despite this, one must take care of challenges like environmental impact and rising raw material prices.

The tire cord fabric markets in the rest of the world namely Latin America, the Middle East and Africa are run at a steady pace owing to its growing automobile sales and industrialization. Passenger and commercial vehicle production in Latin America is on the rise as a result of growing economic development and improvements in infrastructure.

With a thesis on premium and performance vehicles, the Middle East is generating a demand for advanced tire cord fabrics. On the other hand, African automotive sector and infrastructure projects are some of the driving factors towards market development. Growth in the market is hindered by economic volatility and inaccessibility to advanced manufacturing technologies.

Challenges

Raw Material Price Volatility

A significant challenge in the Tire Cord Fabric Market is the volatility in the prices of key raw materials like One major restraint in the tire cord fabric industry is the fluctuation in price of major raw materials such as nylon, polyester and aramid.

These price fluctuations affect manufacturers’ profit margins and complicate supply chains. Since raw materials are typically a major portion of production costs, manufacturers are required to create cost-efficient sourcing strategies to identify and manage risks.

This may mean diversifying suppliers and signing long-term contracts as well as creating alternatives to stabilize costs. Inconsistent pricing may also drive unpredictable financial performance and force companies to modify pricing models and inventory management.

Regulatory Compliance and Sustainability Concerns

Increasing environmental scrutiny of the tire cord fabric sector Governments are also tightening regulations on the manufacture and disposal of synthetic materials, which is pushing manufacturers to seek environmentally-friendly substitutes. Adhering to these standards involves significant R&D investment thus draining financial resources and affecting the current production process.

In addition, the demand for sustainability also necessitates the development of innovative materials such as bio-degradable fiber or recyclable fabrics. Transitioning to these alternatives comes with operational challenges and financial risks, although it will be necessary for remaining compliant and competitive in the market long term.

Opportunities

Advancements in Sustainable Tire Manufacturing

The implementation of sustainable manufacturing practices is a significant opportunity within the Tire Cord Fabric Market. However, with an increasing demand for lightweight, high-strength material, the industry can innovate based on bio-based and recyclable fabrics.

These also comply with the transformation of the world toward sustainability and can help reduce the carbon footprint of tire production. This provides an enormous prospect of solid investigation for the corporations producing eco-friendly tire cords. Research on sustainable materials will lower costs in the long run and also build brand loyalty and trust among the environmentally conscious customers.

Expansion into Emerging Markets

The increasing acceptance of electric and autonomous vehicles is driving the need for innovative tire materials that improve performance and efficiency. Moving forward, the tire cord fabric industry will be well positioned to capitalize on this transition and create fabrics that are tailored to the particular demands of these next generation vehicles. Also, the various opportunities available for the growth of the market in emerging markets due to the growing automotive industry.

As production of vehicles in these areas increase, companies prioritizing innovation and durable material development will be at the forefront. These areas also provide ideal conditions for affordable production and access to new markets for customers.

The tire cord fabric market is evolving rapidly from 2020 to 2024, led by a rise in vehicle production, growing demand for high-performance tires, and new material technologies. The shift to fuel-efficient and electric vehicles (EVs) has also catalyzed innovation of tire reinforcement materials. Moreover, Sustainability concerns have prompted manufacturers to seek for Eco-friendly materials, recycling programs, and energy-efficient production processes.

Looking ahead to 2025 to 2035, the market is expected to be shaped by rising regulatory standards, evolving technology of reinforcement fiber, and higher demand for green tire technology. Smart tire technology, lightweight material, and improved durability will play a critical role in the forecasted growth of the market.

Driven by advancements in material science, regulatory shifts, and sustainability demands, the Tire Cord Fabric Market is on the verge of transformative expansion. While tire reinforcement materials with high performances were developed in 2020 to 2024, the next ten years will focus on green, lightweight and intelligence solutions for tires.

As electric and autonomous vehicles become more prevalent, manufacturers will be pushed to come up with even more durable, efficient and recyclable tires.

Also, companies investing in next-generation reinforcement fibers, smart tire monitoring technologies, and tire sustainable production methods will have competitive advantages. This approach will allow them to adapt to the fast-changing automotive world and set themselves up for future wins in a space that would be defined more by the environmental and technological necessity than ever before.

Comparative Market Analysis

| Market Shift | 2020 to 2024 |

|---|---|

| Regulatory Landscape | Enforcement of safety and environmental regulation affecting tire composition. |

| Technological Advancements | Development of high-tensile polyester, nylon, and aramid fibers for enhanced durability. |

| Industry-Specific Demand | Growing demand from automotive, aerospace, and heavy-duty industries. |

| Sustainability & Circular Economy | Involve recyclable tire cord fabrics and energy bifocal production method. |

| Production & Supply Chain | Disruptions in the supply chain owing to lack of raw material and geopolitical conflicts. |

| Market Growth Drivers | Increased vehicle production, high demand for fuel efficiency and performance tires |

| Market Shift | 2025 to 2035 |

|---|---|

| Regulatory Landscape | Tightening emissions rules and sustainability mandates encouraging bio products. |

| Technological Advancements | Advancements in bio-based fibers, graphene-infused cords, and smart reinforcement technologies. |

| Industry-Specific Demand | Growth in electric vehicles (EVs), autonomous vehicles, sustainable tire applications. |

| Sustainability & Circular Economy | Closed-loop recycling systems and extensive use of bio-based alternatives. |

| Production & Supply Chain | Diversified sourcing strategies, localized production, and block chain for supply chain transparency. |

| Market Growth Drivers | Greater emphasis on EV-specific tire reinforcement, sustainability initiatives, and innovative technologies. |

Rising vehicle production, booming EV adoption, and increasing high-performance tire demand are driving the growth of the USA Tire Cord Fabric Market. Stringent fuel economy regulations in the OEM market push manufacturers towards lightweight, durable reinforcement materials like nylon, polyester, and aramid fibers. The expansion of EV segment is leading to demand for low rolling resistance tires which demand for advanced tire cord fabrics.

As importance of retreading is increasing globally, booming retreading industry is increasing demand for Strong and wear resistance reinforcement fabrics. But high raw material prices and supply chain disruptions are obstacles. There is more investment in sustainable and bio-based tire cord fabrics on the market, which dovetail with the trends toward green mobility.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 6.4% |

The demand for premium vehicles, growth of EVs, and sustainability regulations are fuelling the growth of the UK tire cord fabric sector. This makes strong, lightweight tire reinforcement fabrics a growing requirement as the UK moves to low-emission vehicles.

Post-Brexit, raw material imports have been challenging, yet manufacturers are innovator with recycled and hybrid tire cord fabrics entering the market. High-durability tire reinforcements are driven by luxury and performance vehicles, contributing to higher adoption of aramid and polyester fibers.

The use of recyclable tire-reinforcement materials is gaining traction due to government initiatives promoting sustainable practices under the circular economy. On the other hand, increasing raw material prices coupled with a slow pace shift towards eco-friendly alternatives hampering the growth of the market.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 5.8% |

Germany's automotive industry is a key player in the global market and contributes significantly to the demand for tire cord fabric. The focus of the country on fuel efficiency and durability of tires has resulted in high demand for advanced tire reinforcement materials such as hybrid polyester and aramid fibers.

With the increasing use of self-driven and connected vehicles, the next-generation smart tire, has witnessed acceleration in investments. Germany rules premium and sports car manufacturing and this helps to drive high performance tire cords market. However, the country is advocating sustainable and bio-based reinforcement materials despite high production costs as part of its green automotive endeavors.

| Country | CAGR (2025 to 2035) |

|---|---|

| Germany | 6.1% |

Japan’s tire cord fabric landscape is evolving, driven by technology, EV uptake, and premium tire exports. The presence of prominent tire manufacturers such as Bridgestone and Yokohama promotes the development of high-strength, lightweight, and environmentally friendly reinforcement materials at the same time. Government policies aimed at sustainable mobility are driving tire makers to bio-based and hybrid tire cords.

The export-reliant Japanese tire industry is also supported by rising global hunger for fuel-saving and high-performance tires. Nonetheless, expensive production and reliance on imported raw materials make it challenging. Advanced aramid and nanotechnology-based tire reinforcement materials are witnessing rapid investments in this country.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 5.9% |

Demand for tire cord fabric in South Korea is rising due to its expanding automotive and EV sectors, technology evolution, and government incentives for green mobility. Uniting tire giants like Hankook and Kumho and investing in smart Tire technologies and lightweight reinforcement fabrics. The increase in EV production has resulted in increased demand for low rolling resistance and high-durability tire cords.

The high-performance tires segment of the market is driven by South Korea's support as a major exporter. However, high dependence on raw material imports and fluctuating prices of raw materials are challenges. It emphasizes innovations in sustainable, recycled, and hybrid tire cords.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 6.5% |

The polyester tire cord fabric is mainly used in passenger and commercial vehicle tires owing to its low moisture absorption, dimensional stability, and cost-effective nature. Used primarily in radial tires, it offers superior durability and is used as it provides great strength.

This is majorly aiding the growth of demand for polyester tire cord fabrics in emerging economies, where production is at an all-time high, especially in the Asia-Pacific region. Moreover, rising investment towards fuel-efficient and lightweight tire solutions are anticipated to accelerate polyester-based tire reinforcements market growth.

Manufacturer: Eco-Friendly and Recyclable Polyesters in Pipeline. Increasing transitory marginalization of the bias tires and ongoing shift toward radial tires across the developing regions will influence polyester’s market domination thereby offering persistent growth opportunities for market players.

Nylon tire cord fabric has high tensile strength and also has excellent fatigue resistance and elasticity. It is widely utilized in high-performance tires, commercial vehicle tires, and off-road applications, owing to its robustness against heavy loads and harsh road conditions.

However, while also offering competition as an alternative to polyester, nylon still finds itself crucial for heavy-duty and high-speed tires. In particular, high demand for advanced driver assistance systems is driving the growth of commercial vehicle and off-road vehicle manufacturing industries in the Asia-Pacific and North American regions.

Advancements in the production of nylon grades - like higher modulus, lower shrink - further solidifies the substance’s fit for the ever-advancing next-gen tire. Environmental Impact of Super Plastic Metal Surfaces: Manufacturers are experimenting with sustainable production techniques to lower the environmental impact of polymers while retaining the material's unrivaled performance in high-stress applications.

The dominant segment of the Tire Cord Fabric Market are radial tires, since their properties, such as maintaining durability, are better in comparison to all other tires and radial tires provide better durability, fuel efficiency, comfort of ride. Polyester is the most commonly used reinforcement material for radial tires because it is an economical and stable material.

The growing demand for radial tires for passenger and commercial vehicles, as well as regulatory requirements for fuel-efficient and durable tires, are driving the market growth.

Asia-Pacific, especially China and India, represents the largest consumer of radial tires and thus continues to drive the demand for tire cord fabric in this segment. Moreover, improved tread designs and better material compositions used in radial tire technology are positively impacting their use. The growing emphasis and focus on sustainable mobility solutions is likely to further drive this segment’s growth.

Bias tires, or cross-ply tires, are still used for off-road, agricultural, and specialty vehicles. Typically, bias tires use nylon as a reinforcing material because it has a high strength-to-weight ratio and a high flexural modulus, which gives them impact resistance and load-bearing capability.

The Bias tire market, right now, is continually going after the increasing acceptance of radial tires, and creating for the truck and bus construction, but is still requested because of their high load-bearing capability and impact-resistant properties.

The demand for bias tires in agricultural and construction applications remains steady in North America and parts of Europe. Largely, manufacturers are working on bias tire formulations to bolster wear resistance and lifespan, keeping bias tires relevant in niche markets. Innovative reinforcements may complement tire construction technology for specialized bias tire performance.

The Tire Cord Fabric Market is an essential part of the automotive and transportation sectors, supplying reinforcement materials that increase tire strength, durability, and performance. With Nylon, Polyester, Rayon and Aramid being the respective materials used to make the tire cord fabrics, each has its benefits to the fabrics produced for different types of tires.

The high-demand for fuel-efficient, performance, and durability tires will grow at 10% during the forecast period, which will further add value to growth of the market as well as technological innovation in reinforcement materials. While globally in charge the industry, regional manufacture enables local demand.

The Tire Cord Fabric Market is ever-changing with innovations, and sustainability trends and growing vehicle production. Established players remain at the forefront of innovation in lightweight, high-strength reinforcement materials, while new companies target low-cost or niche applications.

As automotive manufacturers and tire companies increasingly stress on durability and fuel efficiency along with eco-friendly solutions, the demand for tire cord fabrics with advanced technology is expected to rise. It will be propelled by macro trends, like material innovations, sustainability initiatives, and strategic partnerships among the entire industry ecosystem.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Hyosung Corporation | 15-20% |

| Kordsa Global | 12-17% |

| Kolon Industries | 10-14% |

| SRF Limited | 8-12% |

| Teijin Limited | 6-10% |

| Other Companies (Combined) | 40-50% |

| Company Name | Key Offerings/Activities |

|---|---|

| Hyosung Corporation | World’s largest maker of high-strength nylon and polyester tire cord fabrics, with a particular focus on durability and fuel efficiency. |

| Kordsa Global | Advanced tire reinforcement technologies, focusing on sustainable and light materials. |

| Kolon Industries | Offers tire cord fabrics, including notebooks with energy-saving tires. |

| SRF Limited | Produces a diverse array of tire reinforcement fabrics, with an emphasis on economical yet high-durability options. |

| Teijin Limited | Produces tire cords of aramid and polyester that are characterized by superior strength and heat resistance in high-performance tires. |

Key Company Insights

Hyosung Corporation

Hyosung Corporation is the world leader producer of nylon and polyester tire cord fabrics to meet the needs of high-strength, long-lasting and fuel-efficient tires. There are a lot of advanced materials and polymers that we are using, and a lot of R&D also goes into that space, where we are also investing quite a bit, which boosts both performance and sustainability elements of our tire as well. Hyosung which dominates the global market, will supply to the major tire manufacturers by expanding production capabilities. The firm leads the marketplace with its emphasis on light-weight, energy effective reinforcement materials.

Kordsa Global

Kordsa Global Kordsa Global is a leader in reinforcement technologies, producing high-performance tire cord fabrics for durable, fuel-efficient tires. Their commitment to sustainability extends to recycled and bio-based reinforcement solutions, a core audience for its sustainable materials and processes.

Kordsa has a global supply network enabling to serve major automotive markets increasing its competitive power. By focusing on innovation in these areas, the company can create tires that improve vehicle efficiency and safety.

Kolon Industries

Some of the prominent market players include Kolon Industries, a leading supplier of tire reinforcement solutions, including eco-friendly tire cord that helps reduce rolling resistance and enhances fuel efficiency.

Recyclable materials are used by the company to comply with increasing environmental laws while also pushing for sustainable production procedures. Kolon's long-standing expertise in polyester and nylon tire cords allows it to provide a wide array of tire makers with a further range of materials. Investment in research and development keeps the company at the forefront of innovation in tire reinforcement.

SRF Limited

SRF Limited is a significant contributor to the global Tire Cord Fabric Market, offering cost-effective and high-durability reinforcement solutions. The company has a diverse range of tire applications including nylon, polyester, and aramid-based tire cords in its offering.

SRF is focused on continuous improvement in processes through to achieve better strength and durability of products. Focusing on enhancing production capacity, SRF is poised to cater to the growing global reinforced tires demand.

Teijin Limited

Teijin Limited supplies tire manufacturers with high-strength heat-resistant aramid and polyester tire reinforcement fabrics. Our innovative solutions improve tire life and performance, with a focus on high-performance design and commercial vehicle solutions.

Teijin has advanced the development of next-generation tire cord fabrics containing lighter and stronger reinforcement materials to further enhance such properties as fuel efficiency and safety. The business’ strong emphasis on sustainability and material recycling, fits with trends in the industry.

The global Tire Cord Fabric Market is projected to reach USD 9,261.0 million by the end of 2025.

The market is anticipated to grow at a CAGR of 7.1% over the assessment period.

By 2035, the Tire Cord Fabric Market is expected to reach USD 18,388.9 million.

Radial Tires Secure Their Position as Market Leaders with an impressive 41.20% market share in 2023, radial tires enjoy robust consumer trust. Companies can capitalize on this strong preference.

Major companies operating in the Tire Cord Fabric Market Firestone Fibers & Textiles, Century Enka Limited, Indorama Ventures, Shenma Industrial Co., Zhejiang Hailide New Material, Thai Industrial Fabrics, Bekaert Corporation.

In terms of Material Type: the industry is divided into Polyester, Nylon, Polyamide, Aramid, Rayon, Others

In terms of Temperature Range: the industry is divided into Radial Tires, Bias Tires, High-performance Tires

In terms of Application: the industry is divided into Passenger cars, SUVs, MUVs, Light commercial vehicles, Heavy commercial vehicles, Military vehicles, Mining vehicles, Aircrafts, Motorbikes, Bicycles, Agricultural Vehicles, Other Vehicles

The report covers key regions, including North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia, and the Middle East and Africa (MEA).

Anti-seize Compounds Market Size & Growth 2025 to 2035

Industrial Pipe Insulation Market Trends 2025 to 2035

Phosphate Conversion Coatings Market 2025 to 2035

Colloidal Silica Market Demand & Trends 2025 to 2035

Technical Coil Coatings Market Growth 2025 to 2035

Perfluoropolyether (PFPE) Market Size & Trends 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.