The thermoform fill sealing (TFFS) machine industry is growing as food, pharmaceuticals, and consumer goods manufacturers seek efficient, high-speed, and flexible packaging solutions. Brands are looking at automation, sustainability, and precision aspects in order to improve efficiency in the productive process and minimize waste.

Manufacturers are responding by improving machining technology that includes sealing technology through modular designs and eco-friendly material compatibility. The demand for extended shelf life, portion-controlled packaging, and recyclable materials is leading to innovation across the industry.

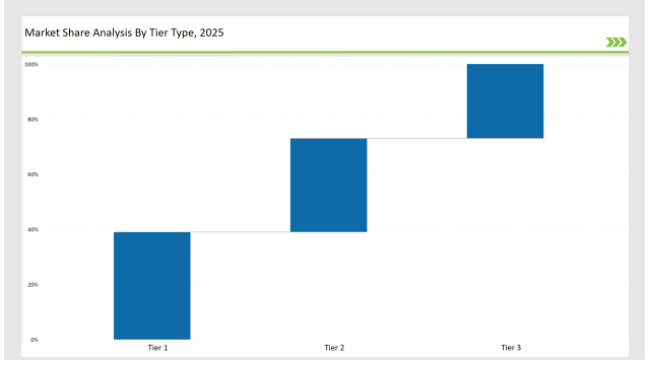

Tier 1 players in the market include MULTIVAC, ULMA Packaging, and ILLIG Maschinenbau, capturing the highest amount of 39% through further technology integration of smart solutions in automation and strong global networks.

Tier 2 companies, including GEA Group, Sealed Air, and Kiefel Packaging, hold 34% of the market by offering cost-effective, customized, and high-efficiency TFFS machines that cater to mid-sized and enterprise-level manufacturers.

Tier 3 consists of regional and specialized manufacturers focusing on compact, energy-efficient, and industry-specific thermoform fill seal machines, holding 27% of the market. These companies emphasize localized service, customizable solutions, and cutting-edge packaging innovations.

Explore FMI!

Book a free demo

Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (MULTIVAC, ULMA Packaging, ILLIG Maschinenbau) | 20% |

| Rest of Top 5 (GEA Group, Sealed Air) | 11% |

| Next 5 of Top 10 (Kiefel Packaging, Bosch Packaging, VC999, Reepack, WEBOMATIC) | 8% |

The thermoform fill sealing machine market serves industries requiring high-speed, hygienic, and sustainable packaging solutions. Companies are investing in automation and digital monitoring to ensure consistency and precision in production.

Manufacturers are enhancing efficiency, flexibility, and sustainability in thermoform fill sealing machines.

Sustainability and efficiency are pushing the thermoform fill sealing machine industry to be more sustainable and efficient. Hybrid systems that manufacturers introduce include reducing material waste, integrating AI-driven automation, and adding eco-friendly materials to sealing. Predictive maintenance and IoT connectivity bring new advancements that help companies optimize performance while reducing operational costs. Brands also invest in quick-changeover features for machines which support small-batch, personalized packaging.

Year-on-Year Leaders

Technology suppliers should focus on automation, digital integration, and sustainable material processing to meet evolving packaging demands. Partnering with global food and healthcare brands will drive adoption and innovation.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | MULTIVAC, ULMA Packaging, ILLIG Maschinenbau |

| Tier 2 | GEA Group, Sealed Air |

| Tier 3 | Kiefel Packaging, Bosch Packaging, VC999, Reepack, WEBOMATIC |

Leading manufacturers are integrating automation, enhancing material compatibility, and improving machine efficiency to meet growing industry demand.

| Manufacturer | Latest Developments |

|---|---|

| MULTIVAC | Launched IoT-connected, high-speed TFFS machines in March 2024. |

| ULMA Packaging | Developed modular, recyclable film-compatible systems in April 2024. |

| ILLIG Maschinenbau | Introduced hybrid material-compatible sealing machines in June 2024. |

| GEA Group | Strengthened its sterile packaging machine lineup in February 2024. |

| Sealed Air | Expanded its automated food safety packaging solutions in August 2024. |

| Kiefel Packaging | Released compact TFFS machines for small-batch production in May 2024. |

| Bosch Packaging | Focused on high-precision, medical-grade sealing technology in September 2024. |

| VC999 | Innovated with eco-friendly vacuum packaging solutions in January 2024. |

The competitive landscape in the thermoform fill sealing machine market is evolving as key players focus on automation, sustainability, and modular technology to maintain strong market positions.

AI-based diagnostics and predictive maintenance will be implemented by the manufacturers to become efficient. New sustainable packaging will emerge from processing recyclable and compostable materials. Safety of products will improve through smart packaging solutions with IoT-enabled monitoring and traceability features. The automation process will reduce labor costs but increase accuracy as the production process is streamlined. Flexible and high-speed thermoform fill sealing machines will play a big role in fulfilling the supply chain demand for convenience foods and pharmaceuticals as the global demand goes up.

Leading players include MULTIVAC, ULMA Packaging, ILLIG Maschinenbau, GEA Group, and Sealed Air.

The top 3 players collectively control 20% of the global market.

The market shows medium concentration, with top players holding 39%.

Key drivers include automation, sustainability, and modular machine designs.

Pan Liner Market Analysis by Polyethylene (PE), Nylon, Polypropylene, Polyester, Polytetrafluoroethylene (PTFE) and Biodegradable Plastics Through 2035

Packaging Films Market Analysis by Product Type, Material Type and End Use Through 2035

Magnetic Closure Boxes Market Trends - Growth & Demand 2025 to 2035

Neoprene Coffee Sleeves Market Growth - Demand & Forecast 2025 to 2035

Mailer Boxes Market Growth – Demand & Forecast 2025 to 2035

Metal Aerosol Packaging Market Growth - Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.