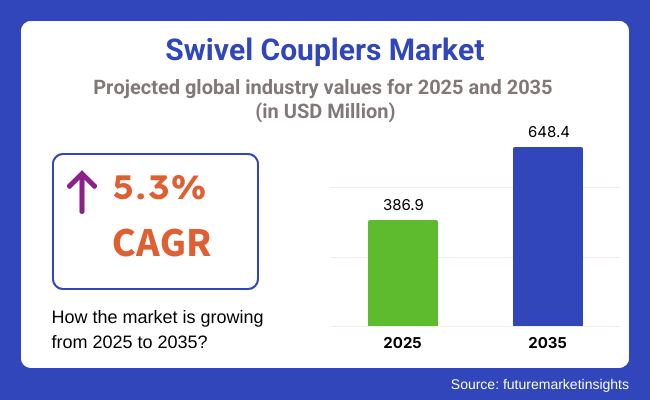

The swivel couplers market is projected to witness steady growth between 2025 and 2035, driven by increasing demand across construction, industrial manufacturing, oil & gas, and infrastructure development sectors. The market is expected to grow from USD 386.9 million in 2025 to USD 648.4 million by 2035, reflecting a CAGR of 5.3% over the forecast period.

Swivel coupler joints are necessary parts in scaffolding, pipe fittings, and machines that are used to create solid and flexible interconnections in building up, pipeline, and machinery work. Their adjustable and rotational structure represents the main reason behind this innovation of efficient load distribution, increased safety of the structure, and better worker still in arduous scaffolding setups and industrial piping systems.

The high infrastructure projects, market urbanization, and configuration of high cannabis plants, mechanisms, and industrial organizational power are the main drivers of high-strength, corrosion-resistant, and load-bearing swivel coupler demand. In addition, implementing lightweight aluminum couplers, AI-assisted structural monitoring, and automated scaffolding assembly is creating new development spaces in the market.

With the emphasis on construction safety, worker productivity, and scaffold high durability, the trends that are of more significance are for swivel couplers that bear more load, resist corrosion, and are lightweight. The shift to modular scaffolding solutions, prefabricated construction materials, and automated pipe fitting are further drivers of technological development in coupler manufacturing.

The construction of sustainable and earthquake-resistant infrastructure by the government is another factor that is affecting the contracts that the industrial builders are giving. They are now able to use high-performance couplers that not only would be safer under different conditions and also meet the strict regulations set up by the authorities.

The adoption of IoT-enabled scaffolding inspection tools and AI-driven load stress analysis is changing again the way swivel couplers are bought by consumer markets.

North America is the leading market for swivel couplers that's propelled by the thriving construction sector, increasing renovation projects, and cyclopean safety regulations. The USA and Canada are the ones observing the increasing trend of industrial architectural being adopting high-strength steel and aluminum swivel couplers in commercial buildings, industrial scaffolding, and oil and gas pipeline installations.

The sprocket of modular construction and modular restorations of bridges is fueling in turn the demand for adaptive swivel couplers that are corrosion-resistant and can adapt the load. Also, government directives on worker safety, quality control on scaffold, and green building materials are routines that will push manufacturers to opt for environmentally friendly coupler redesigns.

Europe is witnessing a consistent growth of the swivel couplers market, spearheaded by Germany, the UK, France, and Italy, the key centers of construction technology, industrial safety legislations, and intelligent infrastructure works. The push for sustainable building, green building materials, and intelligent scaffolding systems by the European Union is fueling the demand for performance-oriented couplers with improved endurance and low environmental footprint.

Germany, the industrial tycoon in prefab construction technology and also in prefab technology, is a key market for high-precision, automation-compatible swivel couplers. UK and France are experiencing the quick turnover of modular housing, large infrastructure projects, and renewable energy plant construction that brings a lot of business for couplers.

Asia-Pacific is the fastest-growing market and the one that is being introduced by China, India, Japan, and South Korea due to the corresponding need for durable scaffold fittings, construction tools, and modular building components. Urbanization, the expansion of the infrastructure projects, and the governmental policies implemented in the form of the smart city initiatives have resulted in a considerable increase of swivel coupler usage in high-rise buildings, bridges, railways and offshore energy installations.

China is number one in construction equipment which causes huge environmental problems and construction in India is the sickest ever, so they are solving these problems by using heavy-duty impact-resistant couplers for the scaffolding of these projects. Japan and South Korea, which are listen to their environmental concerns, make advances in buildings with the special features of high load distribution and safety and thus they are going for high-performance couplers.

The developing areas, especially Brazil, Mexico, Saudi Arabia, and South Africa are seeing industrial companies, planting switch ramps, and green energy setting up more swerving lab fittings where culprits are relevant. The Middle East construction sector's focus on large-scale smart cities, and oil & gas pipeline installations, coupled with modular swimming and heavy-duty pipe gun applications drive the demand for swivel couplers.

Brazil and Mexico are expanding their construction and industrial equipment sectors which is the reason for the adoption of adjustable anti-correlation couplers for the difficult assemblies on bridges, platforms, and the deep water drilling rigs are going up. Other factors include the rising investments of Africa in the urban infrastructure sectors, the acquisitions made in the electric mining, and the residential estate development which is also a coming boost in couplers.

Challenges

Material Costs & Supply Chain Disruptions

The swivel couplers market is significantly depended on sourcing raw materials like steel, aluminum, and cast iron, hence it is most likely to be affected due to the changes in the metal prices, international trade sanctions, and supply chain disruptions. As corrosion-resistant coatings and precision machining become more expensive, the margins of manufacturers and scaffolding contractors decline as a result.

Moreover, the absence of a workforce possessing the necessary skills for precision assembly, safety inspections, and quality testing not only perpetuates the delay but also increases compliance costs. Firms are encouraged to implement cost-effective favorable sourcing alternatives, digital logistics management applications, and lightweight material solutions to achieve the optimal production process and price stability.

Stringent Safety & Compliance Regulations

Swivel couplers are under the constant radar of the focused and detailed construction safety codes such as load-bearing standards and environmental impact regulations created by OSHA (Occupational Safety and Health Administration), EN (European Norms), and ISO (International Organization for Standardization). It is the continuous test, certification, and innovation of materials that manufacturers have to meet, besides these very high compliance requirements, which results in an increase in operational costs.

Absence of load-bearing limits, corrosion resistance measures, and secure workplace means failed project timelines, legal liabilities, plus low project acceptance. Firms should lay their money on investment in AI-infused loading stress evaluation, e-certificates management, and robotic quality control systems to maintain compliance and ensure product quality.

Opportunities

Rise in Smart Construction & Prefabrication Technologies

Modular construction, prefab scaffolding, and AI-powered building automation are the forefront of the movement that brings challenges but also allows the birth of novel, ultralight, and super durable swivel couplers. The combination of IoT with construction methods enabling the fast assembly, and smart load distribution, plus construction work being safer, leads to wanting the next generation of couplers with IoT connectivity, stress sensors, and automated locking mechanisms.

Investments in high-strength composite materials, real-time structural monitoring, and digital twin integration for scaffolding inspections will ensure companies the competitive advantage. The self-locking couplers, which will be mixed with the waterproof, and energy-efficient siding lookup when the sector catches up, will be the ones who lead the way to the faster market influx.

Growth in Infrastructure & Renewable Energy Projects

The boom in offshore wind farms, photovoltaic power plants, and fast rail networks is resulting in the increased procurement of swivel couplers in the construction of renewable energy scaffolding, industrial pipe supports, and heavy-load structural frameworks. Governments have been disbursing funds for local infrastructure improvements, the introduction of green energy, and the renewal of transport systems which have increased the requirement of durable and weather-resistant couplers.

The shift of the industry toward the preferable use of environmentally-friendly solutions, by the use of easily recyclable alloys, anti-corrosion treatments, and lightweight designs, will enable the manufacturers to penetrate the global construction and energy markets with expanded offers.

The swivel couplers market, being the main domain of growth as modular platforms, high-strength materials, and smart construction safety devices are aimed towards long-term expansion, brings forth expected profits for manufacturers, infrastructure developers, and industrial automation companies on a world scale.

Swivel couplers witnessed normal development during 2020 to 2024 owing to a rise in construction and infrastructure projects, and demand for long-lasting, high-performance scaffolding accessories. The loading of couplers at different angles was a prime factor making it pivotal to connect scaffold tubes together.

Seeing that it was far better than the previously used metal parts, the innovations of these light and erosion-resistant materials furthered market growth. Additionally, stringent safety requirements and improved construction standards were a backing factor to the widespread acceptance of swivel couplers of high quality in various regions.

Anticipating the period of 2025 to 2035 the market is likely to go through further developments especially with the increased automation in the construction sphere, a rise in the use of smart scaffolding solutions, and the introduction of environmentally friendly products. The growing focus on worker safety as well as on the efficiency of constructions at high altitudes will also keep driving the demand of high strength and customizable swivel couplers.

Comparative Market Analysis

| Market Shift | 2020 to 2024 |

|---|---|

| Regulatory Landscape | Compliance with global construction safety standards and regional regulations. |

| Technological Advancements | Use of lightweight alloys and anti-corrosion coatings. |

| Industry-Specific Demand | High demand in construction, oil & gas, and industrial maintenance. |

| Sustainability & Circular Economy | Initial steps towards recyclable and eco-friendly materials. |

| Market Growth Drivers | Rising urbanization, infrastructure development, and workplace safety focus. |

| Market Shift | 2025 to 2035 |

|---|---|

| Regulatory Landscape | Stricter safety norms, sustainability mandates, and emphasis on recyclable materials. |

| Technological Advancements | Smart couplers with integrated load monitoring and enhanced durability. |

| Industry-Specific Demand | Expansion into renewable energy, modular construction, and robotic-assisted scaffolding. |

| Sustainability & Circular Economy | Adoption of fully sustainable manufacturing practices and reusable coupler designs. |

| Market Growth Drivers | Increasing adoption of automation, green building initiatives, and advanced scaffolding solutions. |

The USA swivel couplers market is showing steady growth due to the high investments in construction, industrial maintenance, and infrastructure modernization. The government's concerns about workplace safety and compliance with OSHA standards are the main factors driving the demand for high-quality couplers in scaffolding applications.

Moreover, the USA is developing in both commercial and residential construction projects, which makes the need for the latest scaffolding technology. Besides the technological advancement in the construction sector, the increasing adoption of modular and prefabricated construction techniques, the demand for robust and adaptable couplers is also on the rise. Public infrastructure investment, such as highways, bridges, and high-rise buildings, are also supporting the growth of the market.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 5.1% |

The UK swivel couplers market is set to grow steadily as the government implements stricter safety standards, outdoor infrastructure projects expand, and a focus on sustainable building practices becomes the norm. The country is witnessing a considerable rise in scaffolding component prices as it invests more in infrastructure such as roads, railways, and commercial buildings.

In addition, the company's pursuit of worker safety in risky areas of work like scaffolding in high-rise buildings, is contributing to the market growth. The trend towards using eco-friendly building materials and lightweight couplers is causing a shift in the sector towards automation and technology that not only enables the plant to operate more effectively but also creates a safer environment.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 5.2% |

The EU swivel couplers market is on the rise, thanks to growing concerns about construction safety, smart cities initiatives, and upgrades to the infrastructure. The high EU construction safety regulations for scaffolding systems and high-performance couplers that enhance worker safety and stability during construction are the causes of this demand.

Additionally, along with commercial construction, the market is also witnessing rising adoption in the energy and transport sectors. The promotion of green buildings and sustainable construction practices has also encouraged manufacturers to produce environmentally-friendly couplers longer lifespans and higher recyclability.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 5.3% |

The swivel couplers market in Japan is on the rise due to the advances made in the area of earthquake-resistant construction, the increase in public infrastructure investment, and the nation's focus on high-precision engineering. Because of the clamp wear-out, it is more difficult to rotate the machine when you plant it without using a cable, that is, wiring it in the open field.

In addition, the country's deteriorating infrastructure is the main factor leading to the number of maintenance and renovation projects and significantly increasing the demand for scaffolding. Prefabricated and modular construction methods that are used in the urban sector are contributing to the demand for high-quality swivel couplers.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 5.0% |

The swivel couplers market in South Korea is allowing us to expand as the country witnesses an increase in the headcount of the construction industry, high infrastructure investments, and the adoption of the smart building model. The cartels are working hard to further their safety directives and issue new guidelines, leading to the need for more high-quality scaffolding.

High-rise construction projects along with smart cities are the main growth sectors for the swivel coupler manufacturers. Also, the South Korea industrial sector is the driving force for the demand of scaffolding in factory maintenance shipbuilding and energy projects.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 5.4% |

Pressed Swivel Couplers Outsmart the Competition Through Their Affordability and Featherweight Construction

Pressed swivel couplers are the most commonly utilized connection elements in construction and industrial scaffolding because of their exceptionally low cost and minimalist hardware design. The couplers are made of high-quality steel sheets that are pressed and shaped into a reliable and cost-effective coupling solution. They fit easily for structures that are only temporarily assembly and maintenance scaffolds.

Practical paneling and the light weight of pressed swivel couplers induced them into a popular choice of contractors looking for a cost-effective and efficient scaffolding solution. As urbanization and infrastructure development projects spread across the globe, the need for these couplers is expected to surge greatly, especially in emerging markets where cost is the number one factor.

Forged Swivel Couplers Overcoming for High-Power Applications

Forged swivel couplers, due to the superior strength and reliability, are well-suited for heavy-duty applications where bulky weight and increased safety are the priority. The couplers are assembled through precision forging techniques which create higher mechanical properties and better resistance to extreme working conditions.

Industries such as high-rise buildings, shipbuilding, and industrial maintenance depend on forged swivel couplers for their capability of withstanding heavy load and environmental factors. Increasing attention towards workplace safety and strict regulation standards in industrialized areas are further propelling the demand for high-strength forged swivel couplers. Further, developing technologies in the forging process are enhancing the swivel coupler quality and uniformity, pushing its adoption among various industries.

Up to 1100 lbs Segment Becomes the First Choice in Light-Duty Applications

Swivel couplers with a load capacity of up to 1100 lbs are often utilized in light-duty scaffolding systems, such as in residential construction. These couplers are designed for applications that require flexibility without excessive load requirements, making them suitable for small-scale maintenance work, event staging, and temporary scaffolding.

Their ease of installation and maneuverability provide added advantages in applications where frequent adjustments are needed. Particularly in urban areas, we see a rise in small-scale construction and home remodeling that is fueled by the demand for this type of connector.

1100-2300 lbs Segment Experienced Fast Growth in Commercial and Industrial Use

The 1100-2300 lbs load capacity segment is a transitional line between these two - light and heavy - classes of scaffolding equipment. These couplers have gained a solid position in the market for office buildings, medium scale infrastructure projects as well as in the industrial fencing area. Comparing the performance of the joints in terms of weight and load-carrying capacity, the couplers are the good choice for high versatility in various industry applications.

The expansion of commercialization like the opening of shopping malls, office complexes, and the building of manufacturing facilities is one of the encouraging factors for the growth of this segment. Besides, a higher level of scaffold safety awareness and demand for premium quality materials are equally responsible for the recent success of this category of swivel couplers.

The Swivel Couplers market is driven by the increasing demand in construction, infrastructure development, and industrial applications therefore the market is witnessing steady growth. The swivel couplers, which are also referred to as scaffold swivel clamps, are mainly important in the scaffolding systems, as they are the ones that allow the flexible connections between the tubes at different angles.

The substantial use of the raw material in the residential, commercial, and industrial construction projects, besides the maintenance, and renovation works is the major cause of the positive shift to the market.

The need for high-rise buildings and the rapid urbanization ongoing are the steps that are leading the evolution of advanced couplers-equipped scaffolding. Safety mandates that are being issued by the government in many countries are the reasons for necessitating the use of the high-quality swivel couplers of age that are supplying such couplers for ensuring safety to workers and dependability of structures.

Furthermore, a breakthrough in material science has paved the way for the production of no-sustained corrosion, and light-weight couplers that are of high strength; therefore, the market embarks on a fresh course. Market leaders are focusing on increasing their distribution networks and optimizing their products' costs to remain competitive.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Layher Holding GmbH & Co. KG | 18-22% |

| HAKI AB | 15-18% |

| PERI Group | 10-14% |

| Kwikstage Scaffolding | 8-12% |

| BrandSafway | 5-9% |

| Other Companies (combined) | 30-40% |

| Company Name | Key Offerings/Activities |

|---|---|

| Layher Holding GmbH & Co. KG | A global leader in scaffolding and coupler solutions, known for its high-quality, durable, and safety-compliant products. |

| HAKI AB | Specializes in advanced scaffold systems, including high-performance swivel couplers for construction and industrial applications. |

| PERI Group | Provides innovative scaffolding solutions with a focus on modular designs and enhanced safety features. |

| Kwikstage Scaffolding | Offers cost-effective and versatile scaffolding components, including heavy-duty swivel couplers. |

| BrandSafway | Focuses on industrial and commercial scaffolding solutions, with a strong emphasis on regulatory compliance and worker safety. |

Key Company Insights

Layher Holding GmbH & Co. KG

Layher is a trustable name in the industry. It is known as a scaffolding solution provider that is the leading quasi-development company that the world can look for. Its high-performance swivel couplers are meeting the international safety standards. This brand is strong with its innovation, the product's high durability, and personal security for workers.

Layher is under the process of expanding its borders globally, mostly through investments in the newest technological machinery, and broadens its supply network. With the strong vision of becoming the engineering genius among the competitors, the company provides modular scaffolding solutions that are simple and fast to assemble and are highly adaptive.

Besides the integration of smart technologies on construction sites, Layher is introducing the digital monitoring systems which are based on the latest technology increasing the efficiency and security of the scaffolding systems working internationally.

HAKI AB

HAKI AB is engaged in the design and provision of modular scaffolding and access solutions. Besides, the company offers high-performance swivel couplers that are conceived for assembly fast and securely. The firm's love of safety, efficiency, and lightweight materials has made it the customer's number one choice in construction and industrial sectors.

HAKI has focused on the dimension of the net-load capacity and is carrying out the research and development work needed to fully burst the durability of its framework components. Be that as it may, HAKI already has an ultra-strong market segment in Europe, yet the corporation's future rise aims further: it wants to develop into North America and Asia through partnerships with the construction businesses there. Fun fact! The company’s approach to sustainability has led to the adoption of recyclable materials in its manufacturing processes, reducing environmental impact.

PERI Group

PERI Group is the inventor of the scaffolding and formwork solutions. The firm offers a variety of the swivel couplers that are suitable for installation without extra difficulties and that offer safety for the structure itself. The manufacturer is integrating the newest technologies into its scaffolding systems in order to improve the working conditions and save money on labor costs.

The developer has also updated its range of services with the introduction of digital design tools which will allow the construction stuff to visualize and optimize the scaffolding before it is deployed. Driven by the aim of operating in an environmentally friendly way, PERI has started the production of eco-friendly products that create less waste and consume less energy. The company’s good reputation for top quality and dependability is an asset in the eyes of global investors in major infrastructure projects.

Kwikstage Scaffolding

Kwikstage Scaffolding is the pioneer in adaptable scaffolding systems, including durable swivel couplers made for heavy-duty applications. The company is dedicated to offering products that are cost-effective and flexible which leads it to become the winning choice for companies that are looking for scalable scaffolding functioning in construction projects.

Kwikstage still remains a company that is constantly innovating; they have incorporated stronger materials into their product line thus significantly increasing the longevity and durability of the scaffolding components. In a bid to build and improve the strong bond with its customers, the company brings its solutions that can be customized to meet the specific demands of contractors and builders. The company has been able to treble its presence in countries from all over the world where it sells its products on account of the growth that comes from the offering of efficient and safe construction solutions.

BrandSafway

BrandSafway is only about compliant and safe scaffolding solutions provided to the commercial and industrial sector. The company has a full range of couplers such as the swivel couplers which conform to strict industry regulations. The stronghold of BrandSafway in the market is the assurance of quality and the satisfaction of customer needs. The firm has manifested its hopes in the traffic infrastructure modernization project wherein they have provided scaffolding solutions for buildings and factories.

Using the newest manufacturing processes has enabled BrandSafway to assure high stability and support for its scaffolding products in environments that are highly demanding. The firm’s commitment to safety has led to the manufacturer producing innovative accessories for the scaffolding that add to its reliability and durability.

In terms of Product Type, the industry is divided into Pressed Swivel Couplers, Forged Swivel Couplers, and Others.

In terms of Load Capacity, the industry is divided into Up to 1100 lbs, 1100-2300 lbs, and Above 2300 lbs.

In terms of End Use, the industry is divided into Construction Industry, Manufacturing & Fabrication Industry, Water Works, and Others.

The report covers key regions, including North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia, and the Middle East and Africa (MEA).

The global swivel couplers market is projected to reach USD 386.9 million by the end of 2025.

The market is anticipated to grow at a CAGR of 5.3% over the forecast period.

By 2035, the swivel couplers market is expected to reach USD 648.4 million.

The construction industry segment is expected to hold a significant share due to the increasing infrastructure development projects, growing demand for durable and secure scaffolding connections, and rising investments in residential and commercial construction.

Key players in the swivel couplers market include Layher Holding GmbH & Co. KG, HAKI AB, Scafom-rux, and KHK Scaffolding & Formwork LLC.

Table 1: Global Market Value (US$ Million) Forecast by Region, 2018 to 2033

Table 2: Global Market Volume (Units) Forecast by Region, 2018 to 2033

Table 3: Global Market Value (US$ Million) Forecast by Type, 2018 to 2033

Table 4: Global Market Volume (Units) Forecast by Type, 2018 to 2033

Table 5: Global Market Value (US$ Million) Forecast by Load Capacity, 2018 to 2033

Table 6: Global Market Volume (Units) Forecast by Load Capacity, 2018 to 2033

Table 7: Global Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 8: Global Market Volume (Units) Forecast by End Use, 2018 to 2033

Table 9: North America Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 10: North America Market Volume (Units) Forecast by Country, 2018 to 2033

Table 11: North America Market Value (US$ Million) Forecast by Type, 2018 to 2033

Table 12: North America Market Volume (Units) Forecast by Type, 2018 to 2033

Table 13: North America Market Value (US$ Million) Forecast by Load Capacity, 2018 to 2033

Table 14: North America Market Volume (Units) Forecast by Load Capacity, 2018 to 2033

Table 15: North America Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 16: North America Market Volume (Units) Forecast by End Use, 2018 to 2033

Table 17: Latin America Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 18: Latin America Market Volume (Units) Forecast by Country, 2018 to 2033

Table 19: Latin America Market Value (US$ Million) Forecast by Type, 2018 to 2033

Table 20: Latin America Market Volume (Units) Forecast by Type, 2018 to 2033

Table 21: Latin America Market Value (US$ Million) Forecast by Load Capacity, 2018 to 2033

Table 22: Latin America Market Volume (Units) Forecast by Load Capacity, 2018 to 2033

Table 23: Latin America Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 24: Latin America Market Volume (Units) Forecast by End Use, 2018 to 2033

Table 25: Western Europe Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 26: Western Europe Market Volume (Units) Forecast by Country, 2018 to 2033

Table 27: Western Europe Market Value (US$ Million) Forecast by Type, 2018 to 2033

Table 28: Western Europe Market Volume (Units) Forecast by Type, 2018 to 2033

Table 29: Western Europe Market Value (US$ Million) Forecast by Load Capacity, 2018 to 2033

Table 30: Western Europe Market Volume (Units) Forecast by Load Capacity, 2018 to 2033

Table 31: Western Europe Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 32: Western Europe Market Volume (Units) Forecast by End Use, 2018 to 2033

Table 33: Eastern Europe Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 34: Eastern Europe Market Volume (Units) Forecast by Country, 2018 to 2033

Table 35: Eastern Europe Market Value (US$ Million) Forecast by Type, 2018 to 2033

Table 36: Eastern Europe Market Volume (Units) Forecast by Type, 2018 to 2033

Table 37: Eastern Europe Market Value (US$ Million) Forecast by Load Capacity, 2018 to 2033

Table 38: Eastern Europe Market Volume (Units) Forecast by Load Capacity, 2018 to 2033

Table 39: Eastern Europe Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 40: Eastern Europe Market Volume (Units) Forecast by End Use, 2018 to 2033

Table 41: South Asia and Pacific Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 42: South Asia and Pacific Market Volume (Units) Forecast by Country, 2018 to 2033

Table 43: South Asia and Pacific Market Value (US$ Million) Forecast by Type, 2018 to 2033

Table 44: South Asia and Pacific Market Volume (Units) Forecast by Type, 2018 to 2033

Table 45: South Asia and Pacific Market Value (US$ Million) Forecast by Load Capacity, 2018 to 2033

Table 46: South Asia and Pacific Market Volume (Units) Forecast by Load Capacity, 2018 to 2033

Table 47: South Asia and Pacific Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 48: South Asia and Pacific Market Volume (Units) Forecast by End Use, 2018 to 2033

Table 49: East Asia Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 50: East Asia Market Volume (Units) Forecast by Country, 2018 to 2033

Table 51: East Asia Market Value (US$ Million) Forecast by Type, 2018 to 2033

Table 52: East Asia Market Volume (Units) Forecast by Type, 2018 to 2033

Table 53: East Asia Market Value (US$ Million) Forecast by Load Capacity, 2018 to 2033

Table 54: East Asia Market Volume (Units) Forecast by Load Capacity, 2018 to 2033

Table 55: East Asia Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 56: East Asia Market Volume (Units) Forecast by End Use, 2018 to 2033

Table 57: Middle East and Africa Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 58: Middle East and Africa Market Volume (Units) Forecast by Country, 2018 to 2033

Table 59: Middle East and Africa Market Value (US$ Million) Forecast by Type, 2018 to 2033

Table 60: Middle East and Africa Market Volume (Units) Forecast by Type, 2018 to 2033

Table 61: Middle East and Africa Market Value (US$ Million) Forecast by Load Capacity, 2018 to 2033

Table 62: Middle East and Africa Market Volume (Units) Forecast by Load Capacity, 2018 to 2033

Table 63: Middle East and Africa Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 64: Middle East and Africa Market Volume (Units) Forecast by End Use, 2018 to 2033

Figure 1: Global Market Value (US$ Million) by Type, 2023 to 2033

Figure 2: Global Market Value (US$ Million) by Load Capacity, 2023 to 2033

Figure 3: Global Market Value (US$ Million) by End Use, 2023 to 2033

Figure 4: Global Market Value (US$ Million) by Region, 2023 to 2033

Figure 5: Global Market Value (US$ Million) Analysis by Region, 2018 to 2033

Figure 6: Global Market Volume (Units) Analysis by Region, 2018 to 2033

Figure 7: Global Market Value Share (%) and BPS Analysis by Region, 2023 to 2033

Figure 8: Global Market Y-o-Y Growth (%) Projections by Region, 2023 to 2033

Figure 9: Global Market Value (US$ Million) Analysis by Type, 2018 to 2033

Figure 10: Global Market Volume (Units) Analysis by Type, 2018 to 2033

Figure 11: Global Market Value Share (%) and BPS Analysis by Type, 2023 to 2033

Figure 12: Global Market Y-o-Y Growth (%) Projections by Type, 2023 to 2033

Figure 13: Global Market Value (US$ Million) Analysis by Load Capacity, 2018 to 2033

Figure 14: Global Market Volume (Units) Analysis by Load Capacity, 2018 to 2033

Figure 15: Global Market Value Share (%) and BPS Analysis by Load Capacity, 2023 to 2033

Figure 16: Global Market Y-o-Y Growth (%) Projections by Load Capacity, 2023 to 2033

Figure 17: Global Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 18: Global Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 19: Global Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 20: Global Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 21: Global Market Attractiveness by Type, 2023 to 2033

Figure 22: Global Market Attractiveness by Load Capacity, 2023 to 2033

Figure 23: Global Market Attractiveness by End Use, 2023 to 2033

Figure 24: Global Market Attractiveness by Region, 2023 to 2033

Figure 25: North America Market Value (US$ Million) by Type, 2023 to 2033

Figure 26: North America Market Value (US$ Million) by Load Capacity, 2023 to 2033

Figure 27: North America Market Value (US$ Million) by End Use, 2023 to 2033

Figure 28: North America Market Value (US$ Million) by Country, 2023 to 2033

Figure 29: North America Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 30: North America Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 31: North America Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 32: North America Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 33: North America Market Value (US$ Million) Analysis by Type, 2018 to 2033

Figure 34: North America Market Volume (Units) Analysis by Type, 2018 to 2033

Figure 35: North America Market Value Share (%) and BPS Analysis by Type, 2023 to 2033

Figure 36: North America Market Y-o-Y Growth (%) Projections by Type, 2023 to 2033

Figure 37: North America Market Value (US$ Million) Analysis by Load Capacity, 2018 to 2033

Figure 38: North America Market Volume (Units) Analysis by Load Capacity, 2018 to 2033

Figure 39: North America Market Value Share (%) and BPS Analysis by Load Capacity, 2023 to 2033

Figure 40: North America Market Y-o-Y Growth (%) Projections by Load Capacity, 2023 to 2033

Figure 41: North America Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 42: North America Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 43: North America Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 44: North America Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 45: North America Market Attractiveness by Type, 2023 to 2033

Figure 46: North America Market Attractiveness by Load Capacity, 2023 to 2033

Figure 47: North America Market Attractiveness by End Use, 2023 to 2033

Figure 48: North America Market Attractiveness by Country, 2023 to 2033

Figure 49: Latin America Market Value (US$ Million) by Type, 2023 to 2033

Figure 50: Latin America Market Value (US$ Million) by Load Capacity, 2023 to 2033

Figure 51: Latin America Market Value (US$ Million) by End Use, 2023 to 2033

Figure 52: Latin America Market Value (US$ Million) by Country, 2023 to 2033

Figure 53: Latin America Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 54: Latin America Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 55: Latin America Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 56: Latin America Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 57: Latin America Market Value (US$ Million) Analysis by Type, 2018 to 2033

Figure 58: Latin America Market Volume (Units) Analysis by Type, 2018 to 2033

Figure 59: Latin America Market Value Share (%) and BPS Analysis by Type, 2023 to 2033

Figure 60: Latin America Market Y-o-Y Growth (%) Projections by Type, 2023 to 2033

Figure 61: Latin America Market Value (US$ Million) Analysis by Load Capacity, 2018 to 2033

Figure 62: Latin America Market Volume (Units) Analysis by Load Capacity, 2018 to 2033

Figure 63: Latin America Market Value Share (%) and BPS Analysis by Load Capacity, 2023 to 2033

Figure 64: Latin America Market Y-o-Y Growth (%) Projections by Load Capacity, 2023 to 2033

Figure 65: Latin America Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 66: Latin America Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 67: Latin America Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 68: Latin America Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 69: Latin America Market Attractiveness by Type, 2023 to 2033

Figure 70: Latin America Market Attractiveness by Load Capacity, 2023 to 2033

Figure 71: Latin America Market Attractiveness by End Use, 2023 to 2033

Figure 72: Latin America Market Attractiveness by Country, 2023 to 2033

Figure 73: Western Europe Market Value (US$ Million) by Type, 2023 to 2033

Figure 74: Western Europe Market Value (US$ Million) by Load Capacity, 2023 to 2033

Figure 75: Western Europe Market Value (US$ Million) by End Use, 2023 to 2033

Figure 76: Western Europe Market Value (US$ Million) by Country, 2023 to 2033

Figure 77: Western Europe Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 78: Western Europe Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 79: Western Europe Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 80: Western Europe Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 81: Western Europe Market Value (US$ Million) Analysis by Type, 2018 to 2033

Figure 82: Western Europe Market Volume (Units) Analysis by Type, 2018 to 2033

Figure 83: Western Europe Market Value Share (%) and BPS Analysis by Type, 2023 to 2033

Figure 84: Western Europe Market Y-o-Y Growth (%) Projections by Type, 2023 to 2033

Figure 85: Western Europe Market Value (US$ Million) Analysis by Load Capacity, 2018 to 2033

Figure 86: Western Europe Market Volume (Units) Analysis by Load Capacity, 2018 to 2033

Figure 87: Western Europe Market Value Share (%) and BPS Analysis by Load Capacity, 2023 to 2033

Figure 88: Western Europe Market Y-o-Y Growth (%) Projections by Load Capacity, 2023 to 2033

Figure 89: Western Europe Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 90: Western Europe Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 91: Western Europe Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 92: Western Europe Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 93: Western Europe Market Attractiveness by Type, 2023 to 2033

Figure 94: Western Europe Market Attractiveness by Load Capacity, 2023 to 2033

Figure 95: Western Europe Market Attractiveness by End Use, 2023 to 2033

Figure 96: Western Europe Market Attractiveness by Country, 2023 to 2033

Figure 97: Eastern Europe Market Value (US$ Million) by Type, 2023 to 2033

Figure 98: Eastern Europe Market Value (US$ Million) by Load Capacity, 2023 to 2033

Figure 99: Eastern Europe Market Value (US$ Million) by End Use, 2023 to 2033

Figure 100: Eastern Europe Market Value (US$ Million) by Country, 2023 to 2033

Figure 101: Eastern Europe Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 102: Eastern Europe Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 103: Eastern Europe Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 104: Eastern Europe Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 105: Eastern Europe Market Value (US$ Million) Analysis by Type, 2018 to 2033

Figure 106: Eastern Europe Market Volume (Units) Analysis by Type, 2018 to 2033

Figure 107: Eastern Europe Market Value Share (%) and BPS Analysis by Type, 2023 to 2033

Figure 108: Eastern Europe Market Y-o-Y Growth (%) Projections by Type, 2023 to 2033

Figure 109: Eastern Europe Market Value (US$ Million) Analysis by Load Capacity, 2018 to 2033

Figure 110: Eastern Europe Market Volume (Units) Analysis by Load Capacity, 2018 to 2033

Figure 111: Eastern Europe Market Value Share (%) and BPS Analysis by Load Capacity, 2023 to 2033

Figure 112: Eastern Europe Market Y-o-Y Growth (%) Projections by Load Capacity, 2023 to 2033

Figure 113: Eastern Europe Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 114: Eastern Europe Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 115: Eastern Europe Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 116: Eastern Europe Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 117: Eastern Europe Market Attractiveness by Type, 2023 to 2033

Figure 118: Eastern Europe Market Attractiveness by Load Capacity, 2023 to 2033

Figure 119: Eastern Europe Market Attractiveness by End Use, 2023 to 2033

Figure 120: Eastern Europe Market Attractiveness by Country, 2023 to 2033

Figure 121: South Asia and Pacific Market Value (US$ Million) by Type, 2023 to 2033

Figure 122: South Asia and Pacific Market Value (US$ Million) by Load Capacity, 2023 to 2033

Figure 123: South Asia and Pacific Market Value (US$ Million) by End Use, 2023 to 2033

Figure 124: South Asia and Pacific Market Value (US$ Million) by Country, 2023 to 2033

Figure 125: South Asia and Pacific Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 126: South Asia and Pacific Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 127: South Asia and Pacific Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 128: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 129: South Asia and Pacific Market Value (US$ Million) Analysis by Type, 2018 to 2033

Figure 130: South Asia and Pacific Market Volume (Units) Analysis by Type, 2018 to 2033

Figure 131: South Asia and Pacific Market Value Share (%) and BPS Analysis by Type, 2023 to 2033

Figure 132: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Type, 2023 to 2033

Figure 133: South Asia and Pacific Market Value (US$ Million) Analysis by Load Capacity, 2018 to 2033

Figure 134: South Asia and Pacific Market Volume (Units) Analysis by Load Capacity, 2018 to 2033

Figure 135: South Asia and Pacific Market Value Share (%) and BPS Analysis by Load Capacity, 2023 to 2033

Figure 136: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Load Capacity, 2023 to 2033

Figure 137: South Asia and Pacific Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 138: South Asia and Pacific Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 139: South Asia and Pacific Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 140: South Asia and Pacific Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 141: South Asia and Pacific Market Attractiveness by Type, 2023 to 2033

Figure 142: South Asia and Pacific Market Attractiveness by Load Capacity, 2023 to 2033

Figure 143: South Asia and Pacific Market Attractiveness by End Use, 2023 to 2033

Figure 144: South Asia and Pacific Market Attractiveness by Country, 2023 to 2033

Figure 145: East Asia Market Value (US$ Million) by Type, 2023 to 2033

Figure 146: East Asia Market Value (US$ Million) by Load Capacity, 2023 to 2033

Figure 147: East Asia Market Value (US$ Million) by End Use, 2023 to 2033

Figure 148: East Asia Market Value (US$ Million) by Country, 2023 to 2033

Figure 149: East Asia Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 150: East Asia Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 151: East Asia Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 152: East Asia Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 153: East Asia Market Value (US$ Million) Analysis by Type, 2018 to 2033

Figure 154: East Asia Market Volume (Units) Analysis by Type, 2018 to 2033

Figure 155: East Asia Market Value Share (%) and BPS Analysis by Type, 2023 to 2033

Figure 156: East Asia Market Y-o-Y Growth (%) Projections by Type, 2023 to 2033

Figure 157: East Asia Market Value (US$ Million) Analysis by Load Capacity, 2018 to 2033

Figure 158: East Asia Market Volume (Units) Analysis by Load Capacity, 2018 to 2033

Figure 159: East Asia Market Value Share (%) and BPS Analysis by Load Capacity, 2023 to 2033

Figure 160: East Asia Market Y-o-Y Growth (%) Projections by Load Capacity, 2023 to 2033

Figure 161: East Asia Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 162: East Asia Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 163: East Asia Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 164: East Asia Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 165: East Asia Market Attractiveness by Type, 2023 to 2033

Figure 166: East Asia Market Attractiveness by Load Capacity, 2023 to 2033

Figure 167: East Asia Market Attractiveness by End Use, 2023 to 2033

Figure 168: East Asia Market Attractiveness by Country, 2023 to 2033

Figure 169: Middle East and Africa Market Value (US$ Million) by Type, 2023 to 2033

Figure 170: Middle East and Africa Market Value (US$ Million) by Load Capacity, 2023 to 2033

Figure 171: Middle East and Africa Market Value (US$ Million) by End Use, 2023 to 2033

Figure 172: Middle East and Africa Market Value (US$ Million) by Country, 2023 to 2033

Figure 173: Middle East and Africa Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 174: Middle East and Africa Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 175: Middle East and Africa Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 176: Middle East and Africa Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 177: Middle East and Africa Market Value (US$ Million) Analysis by Type, 2018 to 2033

Figure 178: Middle East and Africa Market Volume (Units) Analysis by Type, 2018 to 2033

Figure 179: Middle East and Africa Market Value Share (%) and BPS Analysis by Type, 2023 to 2033

Figure 180: Middle East and Africa Market Y-o-Y Growth (%) Projections by Type, 2023 to 2033

Figure 181: Middle East and Africa Market Value (US$ Million) Analysis by Load Capacity, 2018 to 2033

Figure 182: Middle East and Africa Market Volume (Units) Analysis by Load Capacity, 2018 to 2033

Figure 183: Middle East and Africa Market Value Share (%) and BPS Analysis by Load Capacity, 2023 to 2033

Figure 184: Middle East and Africa Market Y-o-Y Growth (%) Projections by Load Capacity, 2023 to 2033

Figure 185: Middle East and Africa Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 186: Middle East and Africa Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 187: Middle East and Africa Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 188: Middle East and Africa Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 189: Middle East and Africa Market Attractiveness by Type, 2023 to 2033

Figure 190: Middle East and Africa Market Attractiveness by Load Capacity, 2023 to 2033

Figure 191: Middle East and Africa Market Attractiveness by End Use, 2023 to 2033

Figure 192: Middle East and Africa Market Attractiveness by Country, 2023 to 2033

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Power Swivels Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Optocouplers Market

Aerospace Couplers Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA