With the demand for lightweight, durable, and sustainable packaging increasing in the beverage, pharmaceutical, and personal care sectors, the stretch blow molding machines industry is rapidly evolving. Companies are focusing on machine efficiency, automating processes, and energy-saving solutions to lessen their expenses and enhance productivity. Manufacturers are even looking into using recycled PET (rPET) and bio-based plastics to meet sustainability and regulatory objectives.

The companies are investing more in AI-enabled process monitoring, multi-cavity molding technology, and high-speed production capabilities to meet industry requirements. The emerging trend in the industry is hybrid and fully electric machines that consume less energy and are precise. E-commerce as well as premium packaging are driving up demand for packaging, and manufacturers are innovating better designs that offer flexibility and lightweight solutions.

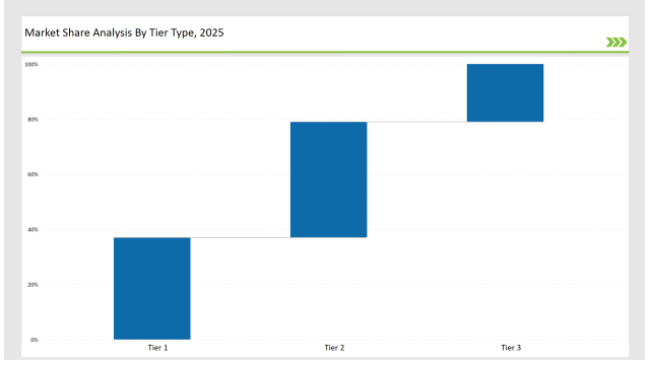

Tier 1 companies, namely Sidel, Krones, and KHS Group, constitutes approximately 37% of the market due to their hold in high-speed blow molding technology, world distribution, and continued innovation.

Tier 2 gives rise to Aoki Technical Laboratory, Nissei ASB, SIPA, and others, which capitalizes about 42% of the market through inexpensive, modular, and energy-efficient stretch-blow molding devices for middle applications.

Tier-3 players consist of regional and niche manufacturers who meet specific customer needs and offer sustainable and compact blow-molding designs 21% of the market share. Their focus predicates an approach on localized production, industry-specific customization, and ecologically designed machines.

Explore FMI!

Book a free demo

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Sidel, Krones, KHS Group) | 19% |

| Rest of Top 5 (Aoki Technical Laboratory, Nissei ASB) | 10% |

| Next 5 of Top 10 (SIPA, SMI Group, Tech-Long, PET Technologies, Chumpower) | 8% |

The stretch blow molding machines industry serves multiple sectors where efficiency, precision, and sustainability are essential. Companies are developing advanced molding systems to meet growing market demands.

The stretch blow molding machines of the future are being improved and optimized by manufacturers not only on aspects such as automation, design sustainability, and speed but also with better integrated real-time monitoring systems for improved accuracy and efficiency in production. Furthermore, many companies are working on next-generation servo-driven technology for high-speed operation but low energy consumption.

Automation and sustainability are transforming the stretch blow molding machine industry. Companies are adopting AI-driven monitoring, servo-driven technology, and smart manufacturing systems to optimize production. Businesses are developing advanced cooling systems to reduce cycle times while maintaining product integrity. Manufacturers are expanding rPET-compatible machinery to meet growing demand for recycled plastic containers. Additionally, firms are integrating real-time defect detection systems to improve production quality and reduce waste.

Year-on-Year Leaders

Technology suppliers should focus on automation, sustainable processing solutions, and precision molding advancements to support the evolving stretch blow molding machine market. Partnering with beverage, healthcare, and personal care brands will drive adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Sidel, Krones, KHS Group |

| Tier 2 | Aoki Technical Laboratory, Nissei ASB, SIPA |

| Tier 3 | SMI Group, Tech-Long, PET Technologies, Chumpower |

Advanced stretch blow moulding machine technology is under development by leading manufacturing companies within areas of AI-based quality control, sustainable materials processing, and high-speed automation. At the same time, IoT-enabled predictive maintenance systems are being integrated to reduce equipment downtime and improve operational efficiencies. Other areas of focus are green cooling systems to cut energy expenditure and sustain production. Finally, manufacturers are improving servo-driven mechanisms to enhance precision and speed in the molding operations.

| Manufacturer | Latest Developments |

|---|---|

| Sidel | Launched AI-powered process optimization in March 2024. |

| Krones | Developed hybrid blow molding machines in April 2024. |

| KHS Group | Expanded rPET-compatible molding solutions in May 2024. |

| Aoki Technical Laboratory | Released compact multi-cavity molding machines in June 2024. |

| Nissei ASB | Strengthened precision molding for pharmaceuticals in July 2024. |

| SIPA | Introduced automated defect detection systems in August 2024. |

| SMI Group | Pioneered lightweight PET molding for beverage packaging in September 2024. |

The stretch blow molding machine market is evolving as companies invest in automation, energy-efficient technology, and sustainable materials processing. They are enhancing machine flexibility to accommodate diverse packaging designs and bottle sizes. Additionally, manufacturers are integrating real-time production analytics to optimize cycle times and improve material efficiency. Companies are also advancing rapid mold-change capabilities to reduce downtime and maximize production output.

The industry will continue integrating AI-powered monitoring, energy-efficient systems, and precision molding technology. Manufacturers will refine ultra-lightweight bottle designs to reduce material use. Businesses will adopt closed-loop rPET processing to enhance circular economy initiatives. Companies will develop smart blow molding machines with IoT connectivity for real-time diagnostics. Additionally, firms will improve mold design technologies to optimize cycle times and increase output efficiency.

Leading players include Krones AG, Sidel, SIPA, Aoki Technical Laboratory, Tech-Long, Chumpower, and Nissei ASB.

The top 3 players collectively control 19% of the global market.

The market shows medium concentration, with top players holding 37%.

Key drivers include automation, sustainability, AI-driven quality control, and high-speed molding advancements.

Cutter Box Films Market Growth – Demand & Trends Forecast 2025-2035

Disposable Tea Flask Market Trends – Growth & Forecast 2025 to 2035

Disposable Lids Market Analysis – Growth & Forecast 2025 to 2035

Cup Carriers Market Insights - Growth & Forecast 2025 to 2035

Custom Boxes Market Trends – Growth & Forecast 2025-2035

Degassing Valves Market Analysis - Growth & Demand 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.