The silage bag market is growing as agriculture and animal farmers seek cost-effective, durable, and high-barrier material to preserve fodder. With increased demand for improved preservation of feeds and reduced spoilage, firms are emphasizing multi-layer films, UV-stable films, and eco-friendly solutions. Firms are adding smart monitoring technologies, high-barrier polymers, and puncture-resistant formulations to enhance the storage life and maintain silage quality.

Producers are making silage bags more efficient with new sealing technology, oxygen barrier coatings, and recyclable materials to meet regulations and environmental standards. The industry is shifting towards heavy-duty, high-capacity silage bags that maximize feed storage efficiency with reduced waste and environmental impact.

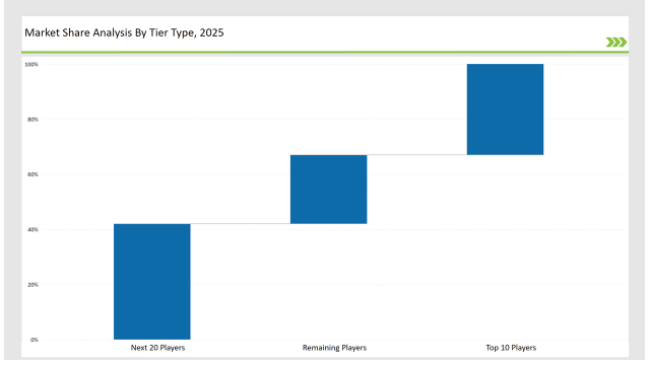

Tier 1 players such as RKW Group, Berry Global, and Dow Chemical have 33% of the market in their control through leadership in high-performance plastic films, large R&D, and global supply chains.

Tier 2 players such as KSI Supply, RPC BPI Agriculture, and Grupo Armando Alvarez have 42% of the market in their control through their low-cost, high-barrier silage bags for various farm activities.

Tier 3 are specialty and regional players who make biodegradable, highly resistant, and specialty silage bags with 25% market share. They are involved in localized manufacturing, green materials, and tailored services for local agricultural needs.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

futureCRM Dashboard Onsite Management Snehal Adsul Back Report Keyword Report Title (H1) Report Sub Title (H2) Report URL URL is available. Report Preview Select As Tab Add Report Preview

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (RKW Group, Berry Global, Dow Chemical) | 16% |

| Rest of Top 5 (KSI Supply, RPC BPI Agriculture) | 9% |

| Next 5 of Top 10 (Grupo Armando Alvarez, Trioplast, Plastar, Sigma Plastics, Poly-Ag) | 8% |

The silage bags industry serves multiple agricultural sectors where durability, protection, and ease of use are critical. Companies are developing innovative bag solutions to improve silage storage and reduce waste. They are integrating high-barrier coatings to minimize oxygen infiltration and extend feed preservation. Additionally, manufacturers are enhancing multi-layer film compositions to strengthen durability against extreme weather conditions.

Manufacturers are optimizing silage bags with enhanced oxygen barriers, multi-layered films, and sustainable materials. They are integrating tear-resistant layers to improve durability and withstand harsh weather conditions. Additionally, companies are developing high-flexibility bags to accommodate different storage capacities with ease. Businesses are also incorporating smart sensors to monitor temperature and humidity levels for better silage preservation.

Storage efficiency and sustainability are transforming the silage bags industry. Silage bag manufacturers are incorporating intelligent monitoring systems, super-thin high-barrier coating, and self-seal seals to ensure efficient feed storage and reduce the environment's negative impacts. Businesses are adopting UV-stable formulations to preserve silage from sun deterioration. Businesses also welcome the application of completely recyclable silage bags for adhering to global regulations. In addition, businesses are incorporating antimicrobial coatings for mold contamination avoidance and optimization of stored silage freshness.

Technology suppliers should focus on automation, digital tracking, and eco-friendly innovations to support the evolving silage bags market. Partnering with large-scale dairy and grain farming operations will drive adoption and market expansion.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | RKW Group, Berry Global, Dow Chemical |

| Tier 2 | KSI Supply, RPC BPI Agriculture, Grupo Armando Alvarez |

| Tier 3 | Trioplast, Plastar, Sigma Plastics, Poly-Ag |

Leading manufacturers are advancing silage bag technology with AI-powered quality control, sustainable materials, and smart monitoring features. They are integrating multi-layered barrier films to enhance protection against oxygen and moisture. Additionally, companies are incorporating RFID-enabled tracking systems to improve inventory management. Businesses are also optimizing sealing technology to ensure airtight storage and prevent spoilage.

| Manufacturer | Latest Developments |

|---|---|

| RKW Group | Launched ultra-durable, high-barrier silage bags in March 2024. |

| Berry Global | Developed recyclable silage bags with puncture resistance in April 2024. |

| Dow Chemical | Expanded its range of multi-layered, oxygen-blocking silage films in May 2024. |

| KSI Supply | Innovated biodegradable silage bags for eco-conscious farming in June 2024. |

| RPC BPI Agriculture | Strengthened UV-resistant and weatherproof silage bag solutions in July 2024. |

| Grupo Armando Alvarez | Introduced antimicrobial-coated silage bags to prevent spoilage in August 2024. |

| Trioplast | Pioneered self-sealing silage bags for airtight storage in September 2024. |

The silage bags market is evolving as companies invest in high-barrier films, AI-driven defect detection, and smart packaging solutions. They are developing self-sealing bags to simplify silage storage. Additionally, manufacturers are integrating RFID tracking for better inventory management. Businesses are also improving eco-friendly solutions to align with sustainability goals.

Manufacturers will continue to add AI-driven quality monitoring, biodegradable packaging, and high-barrier films. They will optimize ultra-long-life puncture-resistant bags to achieve maximum storage life. Firms will create more advanced smart tracking services for better stock management. Firms will also utilize AI-driven automation to optimize manufacturing, reduce spending, and improve sealing accuracy.

Firms will also apply UV-resistance coatings to prevent material erosion under harsh conditions. Manufacturers will further enhance flexibility of bags for varied storage levels. Companies will further utilize environment-friendly inks for labeling to ensure recyclability and reduce chemical wastage.

Leading players include RKW Group, Berry Global, Dow Chemical, KSI Supply, RPC BPI Agriculture, Grupo Armando Alvarez, and Trioplast.

The top 3 players collectively control 16% of the global market.

The market shows medium concentration, with top players holding 33%.

Explore Function-driven Packaging Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.