Shrink sleeve labels market is expanding rapidly as the brands are in search of 360-degree branding solutions, tamper-evident security, and more shelf appeal. Manufacturers are focusing on green materials, high-definition printing, and smart labeling technologies with the rise in demand in food & beverage, pharmaceuticals, and personal care markets. Brands are adding solvent-free inks, AI-driven quality control, and digital embellishments to improve print precision and sustainability.

They are enhancing shrink sleeve labels with reusable PET films, heat-stable inks, and programmable perforations to increase functionality and applicability. The industry is shifting towards lightweight, high-shrink-ratio labels for full-body labelling while minimizing residue.

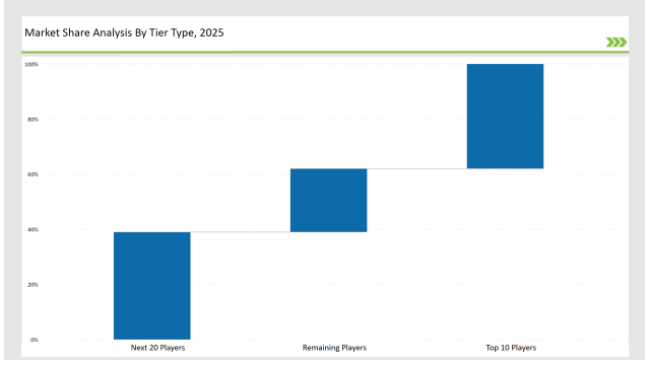

Market leaders Tier 1 players CCL Industries, Berry Global, and Fuji Seal International dominate 38% of the market based on their leadership in high-performance labelling solutions, advanced print techniques, and global supply chains.

Tier 2 players such as Avery Dennison, Macfarlane Group, and Multi-Color Corporation command 39% of the market through offering cheap, digital-printed, and specialty shrink sleeve labels intended for premium packaging applications.

Tier 3 players consist of niche and regional players with specialization in biodegradable, tamper-evident, and barrier-high shrink sleeve labels with 23% of the market share. They are best at local production, intelligent packaging innovation, and sustainable design-driven solutions

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (CCL Industries, Berry Global, Fuji Seal International) | 17% |

| Rest of Top 5 (Avery Dennison, Macfarlane Group) | 12% |

| Next 5 of Top 10 (Multi-Color Corporation, Klöckner Pentaplast, Huhtamaki, Hammer Packaging, Polysack) | 9% |

The shrink sleeve labels industry serves multiple sectors where branding, tamper-evidence, and sustainability are critical. Companies are developing advanced label technologies to enhance product visibility and regulatory compliance.

Manufacturers are optimizing shrink sleeve labels with high-performance coatings, recyclable materials, and interactive labeling solutions. They are incorporating high-opacity films to enhance print clarity and brand visibility. Additionally, businesses are integrating water-resistant coatings to improve durability in moisture-prone environments. Companies are also developing anti-fog shrink labels to maintain product visibility in refrigerated displays.

Sustainability and digitalization are driving the shrink sleeve labels market. Companies are leveraging AI-based defect inspection, solventless ink technologies, and ultra-thin label material to reduce waste. Companies are adopting hybrid printing techniques to improve design flexibility. Companies are expanding their product line with fully recyclable PETG shrink sleeves to meet global sustainability laws. Furthermore, companies are integrating NFC-enabled labels to deliver track-and-trace capabilities and improve product authenticity.

Technology suppliers should focus on automation, high-speed printing, and sustainable materials to support the evolving shrink sleeve labels market. Partnering with beverage, personal care, and pharmaceutical brands will drive innovation and adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | CCL Industries, Berry Global, Fuji Seal International |

| Tier 2 | Avery Dennison, Macfarlane Group, Multi-Color Corporation |

| Tier 3 | Klöckner Pentaplast, Huhtamaki, Hammer Packaging, Polysack |

Leading manufacturers are advancing shrink sleeve labeling technology with AI-powered quality control, sustainable films, and interactive branding features. They are integrating heat-resistant coatings to improve label durability in high-temperature applications. Additionally, manufacturers are optimizing solvent-free adhesive formulations to enhance sustainability and reduce environmental impact.

| Manufacturer | Latest Developments |

|---|---|

| CCL Industries | Launched fully recyclable PET shrink sleeves in March 2024. |

| Berry Global | Developed solvent-free, high-resolution shrink sleeve printing in April 2024. |

| Fuji Seal Intl. | Expanded high-barrier tamper-proof label offerings in May 2024. |

| Avery Dennison | Released QR-enabled shrink sleeve labels in June 2024. |

| Macfarlane Group | Strengthened ultra-thin, high-shrink-ratio label solutions in July 2024. |

| Multi-Color Corp. | Introduced digital embellishment shrink sleeves in August 2024. |

| Klöckner Pentaplast | Pioneered moisture-resistant shrink sleeves in September 2024. |

The shrink sleeve labels market is evolving as companies invest in digital branding, AI-driven defect detection, and high-barrier labeling solutions. They are developing ultra-thin, high-shrink-ratio films to improve sustainability while maintaining durability. Additionally, manufacturers are integrating smart coatings to enhance print quality and resistance to wear. Businesses are also incorporating advanced perforation technology to improve ease of use and recyclability.

Manufacturers will continue to adopt AI-driven quality control, solvent-free inks, and bio-based high-barrier shrink films. Firms will develop ultra-thin, high-shrink-ratio labels to reduce material consumption. Companies will grow QR and NFC-tagged labels for interactive branding and authentication. Hybrid digital-printing will drive customized shrink sleeves. In addition, AI-driven defect detection will enhance quality control, reduce waste, and make production smoother. Firms will refine super-clear shrink films for improved visual appearance and print vibrancy. They will also add antimicrobial coatings to ensure cleanliness and safety in food and pharmaceutical packaging.

Leading players include CCL Industries, Berry Global, Fuji Seal International, Avery Dennison, Macfarlane Group, Multi-Color Corporation, and Klöckner Pentaplast.

The top 3 players collectively control 17% of the global market.

The market shows medium concentration, with top players holding 38%.

Key drivers include sustainability, high-resolution printing, tamper-evidence, and smart labeling.

Explore Function-driven Packaging Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.