During 2024, the worldwide safety valve industry continued to grow steadily with the rising demand from oil & gas, chemical, and power generation sectors. The increasing popularity of smart safety valves, which included IoT-enabled predictive maintenance, largely led the growth. These innovations enabled industries to become more operationally efficient and lower downtime. Also driving the growth was strict government regulations regarding industrial safety, especially in Europe and North America.

The industry also experienced supply chain disruptions through geopolitical tensions and raw material shortages, which briefly affected production timelines. Manufacturers countered these issues, though, by embracing localized supply chains and diversified sourcing strategies.

Forward to 2025 and beyond, demand for safety valves will continue to be robust, especially in fast-industrializing emerging economies. Increased investments in LNG facilities and nuclear power plants will also open up new avenues for safety valve makers.

New digital technologies, including AI-based monitoring systems, are also likely to transform the industry, enhancing reliability and efficiency in sector operations. The industry for safety valves is projected to reach USD 5.2 billion in 2025. The industry is predicted to grow at a CAGR of 8.6% throughout the forecast period and become worth USD 11.87 billion in 2035.

Market Forecast Table

| Metric | Value |

|---|---|

| Market Size (2025E) | USD 5.2 billion |

| Market Value (2035F) | USD 11.87 billion |

| CAGR (2025 to 2035) | 8.6% |

Explore FMI!

Book a free demo

Regional Difference

Regional Investment Trends

ROI Perspectives

Consensus

The most commonly used material was stainless steel (69% overall) due to its corrosion resistance and strength in high-pressure applications.

Regional Variance

Shared Concerns

Regional Differences

Manufacturers

Distributors

End-Users

Worldwide Trends

Regional Focus Areas

Important Variances

Strategic Observations

| Countries | Key Regulations & Mandatory Certifications |

|---|---|

| United States | Safety valves are regulated by OSHA, API 526, ASME Section VIII, and ANSI standards. The oil & gas industry must comply with the EPA and DOT safety norms, respectively. |

| United Kingdom | Ensure pressure equipment directive (PED) compliance and UKCA marking post-Brexit. Any valve in a hazardous area has to be compliant with ATEX. |

| France | Compliance with the EU's Pressure Equipment Directive (PED) is required. Other national safety certifications may also be required in nuclear and chemical industries. |

| Germany | The industrial valves undergo testing in accordance with PED and DIN EN 12266-1. This TÜV certification is often required by law, particularly in the case of high-risk operations. |

| Italy | Pressure relief devices must comply with PED and ISO 4126. These processes often require specific certifications from the chemical and food industries. |

| South Korea | Regulatory bodies like KOSHA oversee safety standards. In the case of pressure relief valves, KSB ISO 4126 certification is compulsory. |

| Japan | The High Pressure Gas Safety Act and JIS (Japanese Industrial Standards) govern safety valve performance and certification for industrial and gas use. |

| China | Adheres to the conditions of GB/T, API. Pressure relief valves are widely used in industries; thus, SELO certification for pressure relief valves is mandatory. |

| Australia-NZ | Meets AS/NZS 3788; WHS requirements: EU exports require compliance with the PED. |

| India | BIS (Bureau of Indian Standards) regulated safety valve standards. The safety valve standards are in compliance with ISO 4126 and IBR. |

The industry in USA is expected to expand steadily at a rate of 7.8% during the forecast period between 2025 and 2035, owing to strong industrial safety regulation and high end-user demand in the oil & gas, chemical, and power industries. OSHA (Occupational Safety and Health Administration) and ASME (American Society of Mechanical Engineers) both have strict safety standards that manufacturers must comply with.

The growing adoption of IoT-driven predictive maintenance among smart safety valves is revolutionizing this industry, especially at plants within refineries and chemical facilities. Demand for high-performance safety valves is also driven by shale gas development and expanded LNG infrastructure. However, supply chain disruptions and pricing volatility for raw materials may present a headwind in the near term.

In the UK, the valve industry will grow at a CAGR of 7.2% through 2025 to 2035, prompted by strict governing environments for applications such as the Pressure Equipment Directive (PED) and the UKCA marking required after Brexit.

The oil & gas industry remains a primary end-user, with continued investment in offshore drilling and hydrogen energy projects driving demand. As industries push forward on sustainable manufacturing and decarbonization strategies, momentum is quickly building to incorporate the best and worst of advanced safety valve technology.

Additionally, the expanding nuclear energy industry in the country, under the auspices of government-sponsored programs, is creating new prospects for development. Trade uncertainties and compliance costs stemming from Brexit, however, are testing the patience of industry operators, which is forcing manufacturers to focus on localized production and strategic partnerships.

France's safety valve industry catalyses with a CAGR of 7.0% through the years 2025-2035, owing to augmenting industrial automation combined with the country's superiority in the nuclear energy industry. As one of the major producers of nuclear energy, the high demand for safety valves is driven by the stringent PED Pressure Equipment Directive, along with domestic nuclear safety regulations. The chemical and pharmaceutical industries add demand, with both being major contributors to the growth of the industry due to the requirement of safety valves to facilitate critical process control.

Moreover, France's allocation to renewable energy resources, such as hydrogen and wind power, is prompting manufacturers to create valves customized to novel applications. High labour costs and stringent environmental regulations could drive a rise in production costs, posing challenges for several companies to earn incomes and indicating innovation in terms of material efficiency and digital integration.

Germany is expected to have the highest CAGR of 7.5% between 2025 and 2035 in the safety valves industry due to strong industrialization and advanced manufacturing excellence. Stringent safety standards in effect in the country, including PED and DIN EN 12266-1, ensure higher demand for safety valve-certified products. The increasing integration of key industries, such as chemical and automotive, along with growing automation and Industry 4.0 adoption, also drives the industry.

New opportunities for safety valves are also evolving from Germany's energy transition drive, such as hydrogen fuel and offshore wind farms. In addition, TÜV certification requirements for industrial products also drive product standardization and conformity. But supply disruptions and higher raw material prices present difficulties, and producers must adopt cost-efficient production techniques.

The chemical industry is also bound to revive the growth of the safety valve industry as its application is heavily demanded in various sectors across the globe. Many countries adopt both PED (Pressure Equipment Directive) guidance and ISO 4126 regulations to ensure manufacturers achieve tight safety standards. The rising demand by the pharmaceutical industry, particularly in sterile and high-purity applications, boosts demand for this industry.

In addition, the strengthening of renewable energy projects in Italy, including solar and biogas plants, is resulting in the emergence of new industry opportunities. Economic uncertainties and divergent industrial production may, however, impact demand stability. To remain competitive, companies are currently investing in intelligent valve technologies and enhancing their export capabilities to international and European industries.

The South Korean industry in this sector is growing robustly at a CAGR of 7.7% in the forecast years of 2025-2035, supported by its high-tech manufacturing sector and bolstering energy sector. As KOSHA (Korea Occupational Safety & Health Agency) imposes strict standards for ensuring safety, it is critical for safety valves to be of the highest quality in these applications. The country's growing LNG and hydrogen energy infrastructure is driving demand.

With the industry moving toward industrial automation, IoT-enabled safety valves are gaining immense popularity. Dependency on imported raw materials and global industry fluctuations continue to be the main issues, regardless. All the companies have taken to R&D and localized manufacturing to reduce risks in a vulnerable and competitive landscape to ensure sustainable growth.

The valve industry sector in Japan is forecast to have a high growth rate of 7.4% during 2025-2035, backed by its highly regulated industrialized economy and strong industry penetration in the energy and automotive sectors. The strictest compliance with the valve industry is mandated by the High Pressure Gas Safety Act and JIS and is reflected in the high quality and reliability of products.

The text introduces new growth opportunities, such as Investment in hydrogen fuel technology and carbon-neutral projects offers new growth opportunities Smart safety valves with predictive maintenance capabilities can thus be easily adopted in India, given the nation's sophisticated manufacturing base.

For example, the nuclear industry represents a key end-user industry requiring high-performance safety valves with the ability to achieve high levels of compliance with strict regulatory demands. An aging labour force and high production costs are long-term problems, so investment in broad employee training is necessary to reduce costs.

The China industry is expected to grow with the highest rate of 8.9% CAGR during the forecast period (2025 to 2035) as China's industrialization and growth in the oil & gas, chemicals, and power generation industries accelerate. The government's "Made in China 2025" policies" are accelerating the promotion of new manufacturing technologies, which will further promote the demand for intelligent safety valves.

Tight safety valve certification is required by the Special Equipment Licensing Office (SELO) to ensure product quality in high-risk industries. Chinese investments in LNG terminals, coal-to-gas conversion, and renewable energy facilities further contribute to the industry expansion.

Foreign producers can still face uncertainties from trade tensions and regulatory changes. Companies are locating production closer to their industries, designing cost-efficient products, and tailoring themselves to the shifting Chinese standards to maintain their edge.

India's safety valve industry is to see an impressive growth of 8.2% CAGR during the forecast period of 2025-2035, owing to rapid industrialization and increasing investments in the oil & gas, power generation, and chemicals sectors. The Bureau of Indian Standards (BIS) and Indian Boiler Regulations (IBR) mandate adherence to industry-wide quality standards with strict valve industry compliance.

Government initiatives such as “Make in India” and highway construction schemes are adding to the demand. The nation's pharmaceutical and food processing industries also serve as significant growth drivers. But there are still problems, from uneven regulation enforcement to price-volatile industry conditions. To capitalize on industry opportunities, suppliers are focusing on cost-effective production, local sourcing, and the development of innovative smart safety valves.

Hydraulic Application of Safety Valves Logistics and transportation of mass goods often require several hydraulic controls and actuators within the same process; these conditions can lead to corrosion and valve failure in dynamic environments. Its popularity is due to its wide application in food & beverage, pharmaceutical, and chemical industries, where contamination control and hygiene are critical.

Marine and water treatment industries also prefer stainless steel safety valves that can withstand extreme conditions. However, cryogenic safety valves represent the fastest-growing segment due to rising demand in LNG, aviation, and healthcare gas applications. Increasing hydrogen-based energy options and developments in space tech are driving requirements for highly specialized valves that can function with ultra-low degrees of tolerance.

The oil & gas industry is the largest consumer of safety valves and, at the same time, the industry with the largest industry demand for valves by percentage. The need for pressure relief and overpressure protection across several application areas, including drilling, refining, and LNG shipping, ensures that demand will remain robust across the industry. Increased offshore oil exploration and shale gas extraction are also driving adoption.

The fastest growth, however, comes in power generation as the world shifts in favour of renewable forms of energy such as hydrogen, wind, and nuclear. The technology in this sector is driven by the need for advanced safety valves in the production and storage of hydrogen, as well as in thermal and nuclear power facilities. The chemical industry is another large industry due to the stringent safety guidelines for handling hazardous materials.

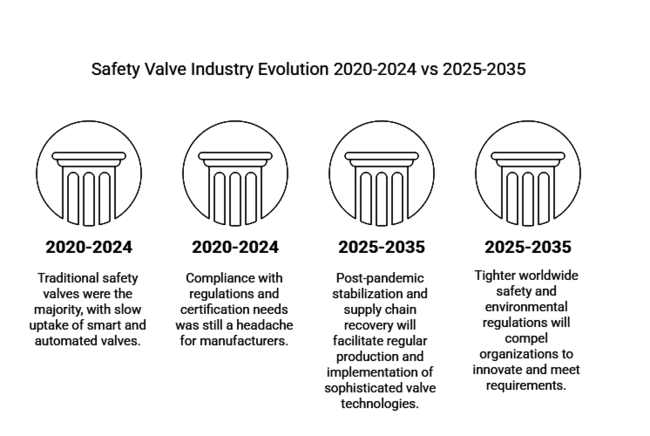

| 2020 to 2024 | 2025 to 2035 |

|---|---|

| The industry experienced steady growth due to rising industrialization, especially in the oil & gas and chemicals industries. | Industry growth will be fuelled by increasing investment in renewable energy, hydrogen initiatives, and Industry 4.0 implementations. |

| The COVID-19 pandemic first disrupted supply chains, causing manufacturing and installation delays. | Post-pandemic stabilization and supply chain recovery will facilitate regular production and implementation of sophisticated valve technologies. |

| Traditional safety valves were the majority, with slow uptake of smart and automated valves. | Predictive maintenance Smart safety valves enabled through IoT will find wide industrial acceptance. |

| Compliance with regulations and certification needs was still a headache for manufacturers. | Tighter worldwide safety and environmental regulations will compel organizations to innovate and meet requirements. |

| Oil & gas industry demand was the key driver of industry growth. | Although oil & gas remains a key driver, power generation, hydrogen energy, and pharmaceuticals will propel the next growth phase. |

The manufacturing, energy, and infrastructure sectors closely link with the valve industry, which is part of the industrial equipment and process safety segment. Industry performance is reliant on industrial growth, regulatory plans, and technical renovations because of its significant role in preventing overpressure anomalies in oil & gas, power generation, chemical processing, and food & beverage industries. Power: Global economic trends such as industrial automation, expansion of renewable energy, and increasing investment in infrastructure are solid demand drivers.

Producers of some safety valves are also benefiting from the switch to green energy sources around the world, including hydrogen, nuclear, and LNG. However, supply chain issues, volatile raw material prices, and geopolitical clashes still dominate challenges in terms of production and distribution.

The leading players in the safety valve industry develop pricing models, products, suppliers, and distribution channels to help them compete globally. Differentiation is rooted in innovation; companies are investing in Internet of Things-enabled smart valves and high-performance materials to drive efficiency and regulatory compliance.

Recently, pricing has remained aggressive, with affordable options accelerating adoption, especially in developing economies. Mergers, acquisitions, and partnerships with energy and industrial companies strengthen supply chains and industry access.

In high-performing enterprise systems, preventative activities are mostly focused on aggressive growth in high-growth industries like India, China, and Southeast Asia, as well as research and development investments in hydrogen-compatible and cryogenic valves that put companies in a position to meet future demand for renewable energy and advanced manufacturing industries.

Emerson Electric Co.

Industry Share: ~20-25%

Emerson is a global leader in automation solutions and is one of the world's leading providers of safety valves with advanced technologies and a strong distribution channel. Emerson aims to deliver top-tier valves for critical applications in the oil and gas, chemical, and power sectors.

Schlumberger Limited (now known as SLB)

Industry Share: ~15-20%

SLB is a major player in the given industry for oil and gas. Leveraging its energy technology expertise, the company uses this advantage to deliver secure and efficient valve solutions.

Baker Hughes Company

Industry Share: ~10-15%

A top player in this industry, Baker Hughes offers advanced valve solutions for upstream and midstream oil and gas production. The company's products center around digital integration and sustainability.

Curtiss-Wright Corporation

Industry Share: ~ 10-12%

Curtiss-Wright is an engineered safety valve company primarily servicing the nuclear, oil & gas, and industrial industries. The company is famous for precision engineering and adherence to high safety standards.

IMI plc

Industry Share: ~8-10%

IMI plc is a industry leader in safety valves and engineering solutions, with a strong focus on innovation and sustainability.

One such product is Emerson Electric Co.'s new range of intelligent safety valves, which integrate IoT control for real-time monitoring and predictive maintenance. The move is in line with the growing demand for the digitization of industry processes.

SLB (formerly Schlumberger) partnered with a major energy company to create next-generation safety valves for carbon capture and storage (CCS) applications. SLB introduced new high-pressure safety valves for offshore drilling operations, enhancing safety and reliability in extreme environments.

Baker Hughes made headlines by purchasing a manufacturer specializing in safety valves with hydrogen experience. With this acquisition, Baker Hughes positions itself at the forefront of the emerging hydrogen economy, providing safety solutions for hydrogen production, storage, and transportation. Baker Hughes also devoted resources to developing valves that are compatible with renewable energy systems.

The new series of safety valves for nuclear power plants from Curtiss-Wright Corporation meet today's regulatory requirements for both performance and safety. The company also expanded its afterindustry support and servicing, offering full-service maintenance and repair solutions to extend the lifespan of its valves.

In Q4 of the year, which ended on 31st December 2023, IMI plc announced the reintroduction of a series of green safety valves that would combat emissions and improve energy efficiency. The company also partnered with a leading pharmaceutical company to develop specialty valves used in biopharmaceutical production.

Weir Group PLC announced the development of smart safety valves for geothermal energy, which, according to the company, would support the transition to renewable energy sources. The company also improved its supply chain resiliency by diversifying its manufacturing base and sourcing key materials locally.

The industry for safety valves offers tremendous growth prospects in renewable energy, hydrogen infrastructure, and digitalization. The shift toward green hydrogen and LNG is creating demand for specialized safety valves with the ability to withstand extreme temperatures and pressures.

Stakeholders need to focus on cryogenic and corrosion-resistant valve technologies to meet this transition. Besides, as nuclear power becomes a favoured source of power, suppliers will need to target high-reliability safety valves that live up to the tight safety measures required in nuclear uses. In addition, all parties should prioritize geographic expansion within rapidly growing countries such as India and Southeast Asia, where the industrialization rate is on the increase.

Financing valve monitoring technology through AI may bring a competitive advantage in forward failure analysis to decrease end-user cost. Mergers and acquisitions of IoT solution providers and specialty material suppliers will further enhance industry positioning and build differentiated product offerings for next-generation safety valve solutions.

Main drivers for increasing adoption are growing industrial automation, stringent safety regulations, and growing hydrogen and LNG projects.

Rapid incorporation of emerging needs has begun in areas as diverse as renewable energy, pharmaceuticals, and advanced manufacturing.

Smart valves with cloud connectivity and predictive maintenance capabilities are reducing downtime and improving operational efficiency.

Meeting changing global regulatory safety standards and price volatility of raw materials are significant challenges.

Yes, ASME, API, and CE marking are essential certifications for regulatory compliance in different regions.

The Industry is segmented into stainless steel, cryogenic, cast iron, alloy and other materials

It segmented among oil & gas, chemical, building & construction, agriculture, metal & mining, food & beverages and other end uses

It is segmented into North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia and Pacific, Middle East and Africa

Automated Material Handling Systems Market - Market Outlook 2025 to 2035

Industrial Vacuum Evaporation Systems Market Analysis - Size & Industry Trends 2025 to 2035

Industrial Temperature Controller Market Analysis - Size & Industry Trends 2025 to 2035

Condition Monitoring Service Market Growth - Trends, Demand & Innovations 2025 to 2035

Ice Cream Processing Equipment Market Growth - Trends, Demand & Innovations 2025 to 2035

Power System Simulator Market Growth - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.