The rotational molding machine market is expanding as industries demand efficient, versatile, and sustainable solutions for manufacturing hollow plastic products. Manufacturers are advancing technologies to meet the needs of industries like automotive, construction, and consumer goods. By 2035, this market is projected to exceed USD 1420.6 million, growing at a compound annual growth rate (CAGR) of 3.7%.

The focus on cost efficiency, durability, and customization drives market growth. Companies deliver machines that enhance production speed, reduce material waste, and meet industry-specific requirements.

| Attributes | Description |

|---|---|

| Projected Market Value (2025F) | USD 1420.6 million |

| Value-based CAGR (2025 to 2035) | 3.7% |

Explore FMI!

Book a free demo

Factors Driving Market Growth

Global Market Share & Industry Share

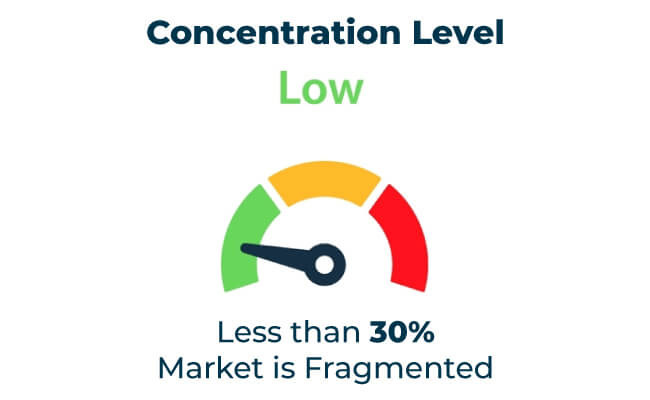

| Category | Market Share (%) |

|---|---|

| Top 3 Players (Ferry Industries, Rotoline, Persico) | 13% |

| Rest of Top 5 Players (NAROTO, Reinhardt) | 08% |

| Next 5 of Top 10 Players | 04% |

Type of Player & Industry Share

| Type of Player | Market Share (%) |

|---|---|

| Top 10 Players | 25% |

| Next 20 Players | 43% |

| Remaining Players | 27% |

Year-on-Year Leaders

Emerging markets in Asia-Pacific, Africa, and Latin America offer significant growth potential. Increasing industrialization and demand for molded plastic products create opportunities for rotational molding machine manufacturers to expand globally. Exporters aligned with local preferences and regulations can capitalize on these growing markets.

| Region | North America |

|---|---|

| Market Share (%) | 40% |

| Key Drivers | Focuses on sustainability and advanced machinery. |

| Region | Europe |

|---|---|

| Market Share (%) | 35% |

| Key Drivers | Leads with eco-friendly practices and technological innovation. |

| Region | Asia-Pacific |

|---|---|

| Market Share (%) | 20% |

| Key Drivers | Industrial growth and affordable production solutions drive demand. |

| Region | Other Regions |

|---|---|

| Market Share (%) | 5% |

| Key Drivers | Emerging markets adopt advanced molding solutions. |

The rotational molding machine market will grow through advancements in automation, smart technologies, and sustainable practices. Companies investing in global market expansion and eco-friendly solutions will lead the industry. Collaboration with end-users and regulatory agencies will further enhance opportunities.

| Tier | Key Companies |

|---|---|

| Tier 1 | Ferry Industries, Rotoline, Persico |

| Tier 2 | NAROTO, Reinhardt |

| Tier 3 | Fixopan Machines, ZhongyunTech |

The rotational molding machine market is set for significant growth as sustainability, automation, and industrial demand shape industry trends. Companies prioritizing eco-friendly practices, advanced technologies, and global market expansion will lead the market. Collaboration with industry stakeholders and adherence to regulations will unlock additional growth opportunities.

Key Definitions

Abbreviations

Methodology

This report integrates primary research, secondary data, and expert insights. Findings are validated through interviews with industry professionals and end-users to ensure accuracy and reliability.

Market Definition

The rotational molding machine market includes the development and use of advanced, sustainable, and customizable equipment for producing hollow plastic products. These machines serve industries like automotive, construction, consumer goods, and industrial applications.

Industries like automotive, construction, consumer goods, and industrial applications rely heavily on rotational molding machines for manufacturing durable and lightweight products.

Manufacturers design energy-efficient machines and support the use of recyclable materials to reduce environmental impact.

North America and Europe lead the market due to advanced technologies and strong demand for eco-friendly solutions.

Challenges include high initial costs, regulatory compliance, and maintenance needs for advanced machinery.

Automation, smart control systems, and advanced materials are key innovations driving the market forward.

Hinged Food Containers Market Insights & Growth 2025 to 2035

Insulated Cup Sleeves Market Analysis – Size, Growth & Forecast 2025 to 2035

Kraft Liner Market Analysis by Product Type, Basis Weight, Application and End Use Through 2025 to 2035

Layer Pads Market from 2025 to 2035

Laminated Tube Closure Market from 2025 to 2035

Lubricant Packaging Market by Material from 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.