The Rotary Tray Sealers Market is estimated to be valued at USD 3.3 billion in 2025 and is projected to reach USD 6.0 billion by 2035, registering a compound annual growth rate (CAGR) of 6.0% over the forecast period.

| Metric | Value |

|---|---|

| Rotary Tray Sealers Market Estimated Value in (2025 E) | USD 3.3 billion |

| Rotary Tray Sealers Market Forecast Value in (2035 F) | USD 6.0 billion |

| Forecast CAGR (2025 to 2035) | 6.0% |

The rotary tray sealers market is witnessing significant advancement driven by the growing emphasis on automation, hygiene, and operational efficiency within packaging processes. As consumer demand rises for ready-to-eat meals and perishable goods, industries are shifting toward rotary sealing systems that offer precision, leak-proof sealing, and high-speed throughput. Adoption is being propelled by the expansion of food processing units, stringent food safety regulations, and the need to reduce human intervention in the packaging line.

Additionally, manufacturers are increasingly integrating rotary tray sealers with smart automation technologies and modular conveyor systems to enhance performance and flexibility across high-volume operations. Advancements in sealing materials, coupled with demand for sustainable and tamper-evident packaging formats, are also contributing to increased utilization.

The global packaging landscape is further evolving with demand for convenience, longer shelf life, and presentation quality, which rotary tray sealers are well-positioned to address In the coming years, the market is expected to witness continued growth due to technological upgrades, growing investments in automation, and increased focus on packaging integrity.

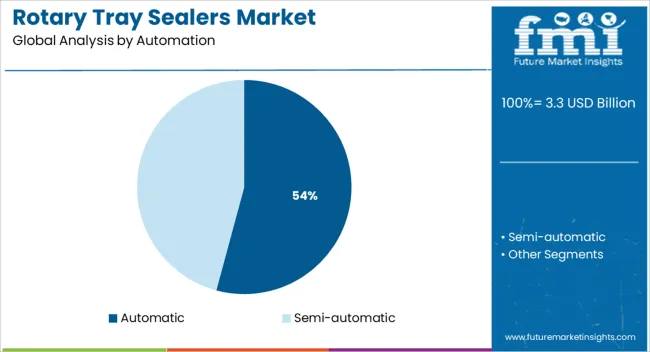

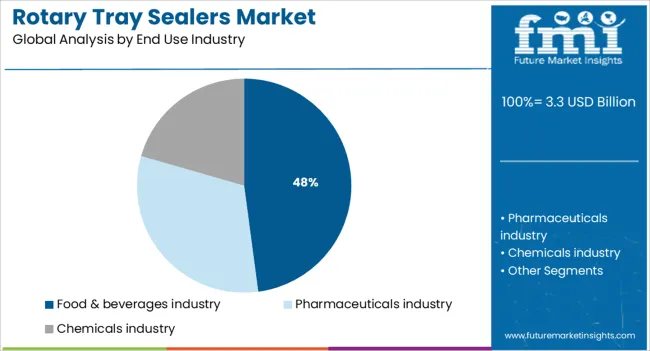

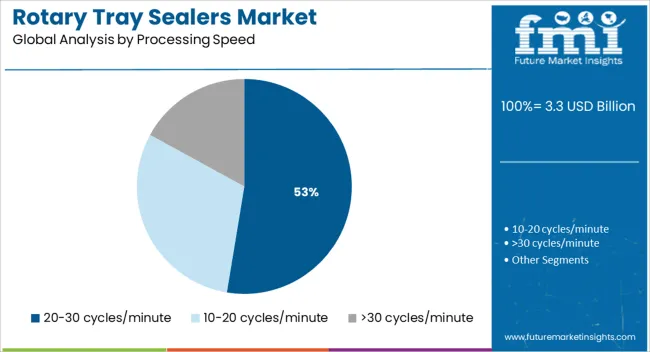

The market is segmented by Automation, End Use Industry, and Processing Speed and region. By Automation, the market is divided into Automatic and Semi-automatic. In terms of End Use Industry, the market is classified into Food & beverages industry, Pharmaceuticals industry, and Chemicals industry. Based on Processing Speed, the market is segmented into 20-30 cycles/minute, 10-20 cycles/minute, and >30 cycles/minute. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The automatic segment is projected to account for 54.2% of the rotary tray sealers market revenue share in 2025, making it the most prominent automation category. This leading position is driven by the increasing requirement for uninterrupted, high-throughput operations in industries seeking to minimize labor dependency and production downtime.

Automatic rotary tray sealers offer consistent sealing quality, reduced human error, and improved cycle accuracy, which have become critical factors in environments with strict food safety and productivity standards. The integration of programmable logic controllers, vision inspection systems, and real-time monitoring features has further enhanced operational control and traceability.

As packaging lines are increasingly linked to broader manufacturing execution systems, the ability of automatic tray sealers to align with digital workflows has made them indispensable in modern production settings Additionally, their scalability and adaptability across a wide range of tray materials and product types have made them favorable among medium to large-scale production facilities seeking automation-led efficiency.

The food and beverages industry is anticipated to represent 47.9% of the total revenue share in the rotary tray sealers market in 2025, reaffirming its dominance among end-use industries. This segment’s growth is being driven by the surging demand for pre-packaged, ready-to-eat, and convenience food products, which require secure and hygienic sealing solutions.

Rotary tray sealers have gained strong traction in this industry due to their ability to ensure contamination-free sealing, preserve product freshness, and support modified atmosphere packaging requirements. The increasing global emphasis on food safety compliance, shelf-life extension, and production traceability has further encouraged the adoption of advanced sealing systems within food processing units.

In addition, rising urbanization, changing dietary habits, and the growth of organized food retail channels have amplified packaging volumes, necessitating scalable and robust sealing equipment The segment's continued demand is also being supported by the shift toward sustainable packaging materials that require precision sealing technologies, which rotary tray systems effectively deliver.

The 20 to 30 cycles per minute subsegment is expected to hold 52.6% of the rotary tray sealers market revenue share in 2025, establishing itself as the leading category by processing speed. This segment’s dominance is attributed to its optimal balance between speed and product integrity, meeting the needs of medium- to high-volume production environments.

Sealers operating in this speed range are widely preferred for their ability to handle diverse product types while maintaining consistent seal quality, especially in sectors where precision and hygiene are paramount. The flexibility to adapt to varying tray sizes and film types without compromising output has made this speed category particularly valuable for food processors and packaging contract manufacturers.

Moreover, equipment in this segment is often designed with modular configurations, enabling seamless integration with upstream and downstream automation systems The increasing requirement for throughput efficiency without excessive energy consumption or equipment wear has positioned the 20 to 30 cycles per minute segment as the most operationally effective choice for scalable production lines.

The global packaging industry is changing rapidly, which is driven by demands from suppliers and consumers. It has been observed, that an excellent product presentation increases appeal of the product. Rotary tray sealers are machines, used for sealing filled trays. Here, filled trays are placed on turntable of rotary tray sealers, which rotate beneath vacuum chamber assembly and heat seal head.

Rotary tray sealers find packaging applications in different industries and products such as, the food and beverage industry, cosmetics industry, healthcare and pharmaceuticals. In addition, rotary tray sealers manufacturers are focused on technology integration, which means it comes with inbuilt printers, coders, depositors.

This is expected to increase competition and further drive the global rotary tray sealers market. For instance, rotary tray sealers are useful in ready meal and fresh food packaging. Rotary tray sealers help in faster sealing of trays, with sealing speed up to 20-26 trays per minute.

To cope with increasing demand for convenience and aesthetic packaging, manufacturers across the world emphasize on adopting automated production technology. Rotary tray sealers provide an ideal choice to increase production output, and therefore, the global rotary tray sealers market is anticipated to enjoy high preference among manufacturers across the globe.

Since their inception, rotary sealers applications have been primarily used for sealing purposes. Nowadays, rotary tray sealers are equipped with full production line, has in-feed conveyor, automatic transfer, depositors, and fillers. There are certain factors, which are expected to fuel growth of the global rotary tray sealers market.

One such factor is that it provides customizability in specifications of rotary tray sealers. In today’s market, packaging manufacturers have various needs to suit their manufacturing operations. Availability of rotary tray sealers in different sealing and speeds enables manufacturers to decide which is most suitable for their manufacturing units.

In addition, a growing number of manufactures opting for automation in emerging economies is expected to drive growth of the global rotary tray sealers market. Rotary tray sealers increase production volume per unit time, which makes them an asset to manufacturers to meet the growing demand for packaged products.

Despite the positive outlook, high power consumption and fluctuating energy rates, are two of the major factors that might hamper growth of the global rotary tray sealers market.

Rotary Tray Sealers market can be segmented as follows:

Few of the key players operating in the global Rotary Tray Sealers market are - David Henderson Food Machinery, ORICS, Total Packaging Systems Ltd, Vortech Food Machinery, Nelipak Healthcare Packaging, Propakkoreaco Ltd., Pack Line.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The global rotary tray sealers market is estimated to be valued at USD 3.3 billion in 2025.

The market size for the rotary tray sealers market is projected to reach USD 6.0 billion by 2035.

The rotary tray sealers market is expected to grow at a 6.0% CAGR between 2025 and 2035.

The key product types in rotary tray sealers market are automatic and semi-automatic.

In terms of end use industry, food & beverages industry segment to command 47.9% share in the rotary tray sealers market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Rotary Shaping File Market Size and Share Forecast Outlook 2025 to 2035

Rotary DIP Switch Market Size and Share Forecast Outlook 2025 to 2035

Rotary Tables with Torque Motor Drive Market Size and Share Forecast Outlook 2025 to 2035

Rotary Band Heat Sealer Market Size and Share Forecast Outlook 2025 to 2035

Rotary Heat Pump Compressors Market Size and Share Forecast Outlook 2025 to 2035

Rotary and RF Rotary Joints Market Size and Share Forecast Outlook 2025 to 2035

Rotary Drilling Rig Market Size and Share Forecast Outlook 2025 to 2035

Rotary Tool Market Size and Share Forecast Outlook 2025 to 2035

Rotary Scroll Air Compressor Market Size and Share Forecast Outlook 2025 to 2035

Rotary Indexer Market Analysis - Share, Size, and Forecast 2025 to 2035

Rotary Hopper Market Analysis by Material, Capacity, Application and Region: Forecast for 2025 and 2035

Rotary Limit Switches Market Growth - Trends & Forecast 2025 to 2035

Rotary Encoder Market

Rotary Steerable System Market

Rotary Knife Cutters Market

Rotary Sealers Market

Oil Rotary Pump Market Size and Share Forecast Outlook 2025 to 2035

NiTi Rotary File Market Size and Share Forecast Outlook 2025 to 2035

Indoor Rotary High Voltage Disconnect Switch Market Size and Share Forecast Outlook 2025 to 2035

Compact Rotary Actuator Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA