The market for recyclable cups is growing as consumers and brands are concerned with sustainability, convenience, and regulatory compliance. Foodservice, beverage, and retail markets' growing demand is forcing manufacturers to produce fully recyclable, compostable, and reusable cup solutions. Brands are adding plant-based coatings, water-based inks, and advanced barrier technologies to make the cups more recyclable without sacrificing durability and functionality.

Firms are investing in AI-driven quality inspection, automated production lines, and lightweight material innovations to enhance efficiency and sustainability. The sector is transitioning to fiber-based, PET, and biopolymer materials for cups to reduce plastic waste and align with circular economy ambitions.

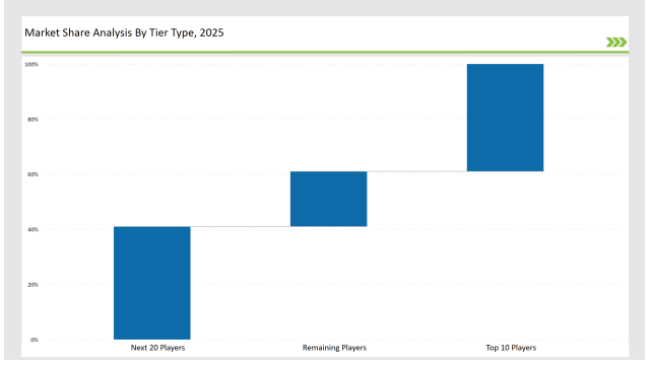

Tier 1 players, including Huhtamaki, Dart Container, and Georgia-Pacific, hold 39% market share due to their leadership in sustainable cup solutions, high-volume manufacturing, and advanced material technologies.

Tier 2 companies, such as WestRock, Pactiv Evergreen, and Genpak, command 41% of the market share by offering cost-effective, recyclable, and customized cup solutions for foodservice, retail, and corporate companies.

Tier 3 are niche and regional players who specialize in biodegradable, compostable, and smart cups with 20% market share. They have expertise in localized production, plant-based inputs, and green packaging.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Huhtamaki, Dart Container, Georgia-Pacific) | 17% |

| Rest of Top 5 (WestRock, Pactiv Evergreen) | 12% |

| Next 5 of Top 10 (Genpak, Fabri-Kal, Stora Enso, Eco-Products, Lollicup) | 10% |

The recyclable cups industry serves multiple sectors where sustainability, branding, and functionality are essential. Companies are developing advanced cup designs to meet evolving consumer and regulatory demands.

Manufacturers are optimizing recyclable cups with sustainable materials, leak-proof designs, and smart branding features. They are incorporating advanced moisture-resistant barriers to enhance durability and maintain beverage quality. Additionally, companies are developing biodegradable lids and cup sleeves to offer fully sustainable solutions.

Innovation and sustainability are revolutionizing the recyclable cups business. Companies are employing AI-based defect detection, plant-derived coating, and digital printing to increase the recyclability and brandability of the products. Companies are producing ultra-lightweight cups with structurally reinforced design to minimize material usage. Manufacturers are introducing water-based barrier coatings to eradicate polyethylene (PE) linings. In addition, companies are incorporating heat-resistant, biodegradable alternatives for improved compostability.

Technology suppliers should focus on automation, sustainable coating solutions, and high-speed production enhancements to support the evolving recyclable cups market. Partnering with foodservice, retail, and event brands will accelerate adoption and innovation.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Huhtamaki, Dart Container, Georgia-Pacific |

| Tier 2 | WestRock, Pactiv Evergreen, Genpak |

| Tier 3 | Fabri-Kal, Stora Enso, Eco-Products, Lollicup |

Industry leaders are developing recyclable cup technology with AI-based manufacturing, eco-friendly materials, and environmentally friendly coatings. Industry players are designing ultra-thin cup structures to minimize material use while maintaining strength. Manufacturers are also adding compostable heat-resistant linings to improve performance for hot beverages. Companies are also optimizing cup stackability for efficient storage and transportation.

| Manufacturer | Latest Developments |

|---|---|

| Huhtamaki | Launched plastic-free fiber cups in March 2024. |

| Dart Container | Developed RPET and biodegradable cup lines in April 2024. |

| Georgia-Pacific | Expanded water-based coating technology in May 2024. |

| WestRock | Released fully compostable hot beverage cups in June 2024. |

| Pactiv Evergreen | Strengthened spill-proof, durable cup designs in July 2024. |

| Genpak | Introduced plant-based PLA-coated fiber cups in August 2024. |

| Fabri-Kal | Pioneered clear, lightweight RPET cold beverage cups in September 2024. |

The recyclable cup market is evolving with businesses investing in sustainable material, defect inspection based on AI, and interactive branding solutions. They are developing plant-based coatings to replace traditional plastic linings and increase recyclability. Manufacturers are also optimizing manufacturing processes to reduce water and energy consumption in cup manufacturing.

Manufacturers will increasingly use AI-driven defect detection, plant-based coatings, and fully compostable materials. Companies will maximize high-barrier coatings for increased recyclability and reduced plastic linings. Companies will expand smart-enabled branding with QR codes and digital authentication. High-speed automation will also be more efficient, reducing the cost and availability of sustainable cups. Companies are also developing next-generation bio-based polymers to enhance cup durability without sacrificing full recyclability. Manufacturers will produce new, lightweight cup structures to reduce material consumption without compromising on strength.

Leading players include Huhtamaki, Dart Container, Georgia-Pacific, WestRock, Pactiv Evergreen, Genpak, and Fabri-Kal.

The top 3 players collectively control 17% of the global market.

The market shows medium concentration, with top players holding 39%.

eye drivers include sustainability, lightweight materials, high-speed automation, and smart branding solutions.

Explore Tech in Packaging Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.