The market for polyester straps is undergoing change as corporations seek high strength, low cost, and green alternatives to traditional packaging materials. With growing requirements in logistics, construction, and industrial uses, corporations are crafting high-tensile strength PET straps, reclaimed materials, and new sealing techniques. Corporations are integrating automation, AI-facilitated quality control, and lightened construction to provide greater efficiency with reduced environmental impact.

The producers are streamlining the manufacturing processes to manufacture recyclable, UV-resistant, and water-resistant polyester straps that have high resistance to extreme conditions. The industry is shifting towards low-cost, high-performance alternatives that replace metallic strapping in heavy-duty use.

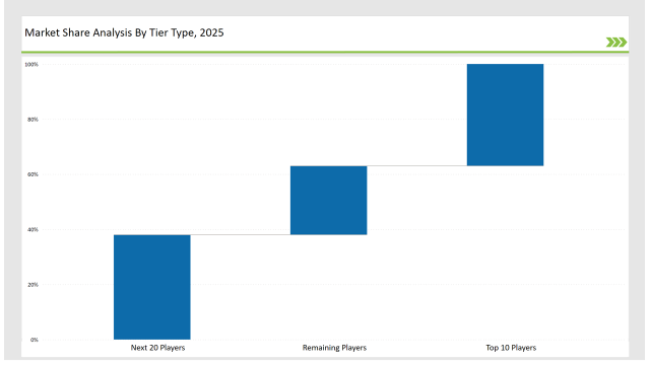

Tier 1 players such as FROMM Packaging, Signode, and Teufelberger have a market share of 37% due to their hold in high-strength polyester strapping solutions, cutting-edge automation systems, and global distribution systems.

Tier 2 competitors such as Samuel Strapping, Mosca GmbH, and Polychem Corporation hold 38% market share through offering low-cost, tailor-made, and specialty strapping systems for logistics, automotive, and industrial sectors.

Tier 3 are specialty and regional players involved in recycled, heavy-duty, and tamper-evident polyester straps with a market share of 25%. They deal in localized manufacturing, innovative solutions for strapping, and sustainable designs.

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (FROMM Packaging, Signode, Teufelberger) | 17% |

| Rest of Top 5 (Samuel Strapping, Mosca GmbH) | 12% |

| Next 5 of Top 10 (Polychem Corporation, TITAN Umreifungstechnik, Cyklop, Greenbridge, PAC Strapping) | 8% |

The polyester straps industry serves multiple sectors where strength, durability, and sustainability are essential. Companies are developing high-performance strapping solutions to support packaging efficiency and environmental responsibility.

Manufacturers are optimizing polyester straps with high-strength materials, sustainable compositions, and automated tensioning solutions. They are enhancing elasticity to improve shock absorption and load stability. Additionally, companies are developing corrosion-resistant coatings to extend the lifespan of polyester straps in harsh environments.

Sustainability and automation are transforming the polyester straps industry. Companies are adopting AI-powered defect detection, solvent-free adhesives, and lightweight reinforcement technologies to improve performance. Businesses are developing fiber-enhanced PET straps to replace steel alternatives. Manufacturers are launching biodegradable polyester strapping solutions to meet global sustainability goals. Additionally, firms are integrating RFID-enabled straps for better load tracking and inventory management.

Technology suppliers should focus on automation, eco-friendly materials, and smart tracking features to support the evolving polyester straps market. Partnering with logistics, construction, and industrial sectors will drive innovation and adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | FROMM Packaging, Signode, Teufelberger |

| Tier 2 | Samuel Strapping, Mosca GmbH, Polychem Corporation |

| Tier 3 | TITAN Umreifungstechnik, Cyklop, Greenbridge, PAC Strapping |

Leading manufacturers are advancing polyester strapping technology with AI-powered production, sustainable materials, and high-speed packaging solutions. Companies are refining lightweight, high-strength designs to improve efficiency and lower costs. Additionally, businesses are expanding RFID-enabled strapping solutions to enhance traceability and security. Manufacturers are also adopting low-energy processing techniques to reduce carbon footprints.

| Manufacturer | Latest Developments |

|---|---|

| FROMM Packaging | Launched 100% recycled PET strapping solutions in March 2024. |

| Signode | Developed automated high-speed strapping machines in April 2024. |

| Teufelberger | Expanded its moisture-resistant polyester straps in May 2024. |

| Samuel Strapping | Released ultra-light PET straps for logistics in June 2024. |

| Mosca GmbH | Strengthened biodegradable PET strap offerings in July 2024. |

| Polychem Corp | Introduced tamper-proof, high-visibility PET straps in August 2024. |

| TITAN Umreifungstechnik | Pioneered shock-absorbent PET straps in September 2024. |

The polyester straps market is evolving as companies invest in sustainable materials, AI-driven defect detection, and RFID tracking features. They are enhancing production techniques to improve strap flexibility and tensile strength. Additionally, manufacturers are integrating advanced coating technologies to increase resistance against moisture and UV exposure.

Manufacturers will continue integrating AI-driven quality control, biodegradable PET materials, and high-speed automation. Companies will refine ultra-lightweight, high-tensile strapping designs to improve efficiency. Businesses will expand smart strapping solutions with QR-enabled tracking for real-time shipment visibility. Energy-efficient processing techniques will become standard. Additionally, AI-powered analytics will optimize production, reducing waste and improving cost efficiency.

Leading players include FROMM Packaging, Signode, Teufelberger, Samuel Strapping, Mosca GmbH, Polychem Corporation, and TITAN Umreifungstechnik.

The top 3 players collectively control 17% of the global market.

The market shows medium concentration, with top players holding 37%.

Key drivers include sustainability, automation, high-tensile strength, and smart tracking solutions.

Explore Packaging Consumables and Supplies Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.