Pneumatic Actuator Market Share Analysis Outlook (2025 to 2035)

The global market for pneumatic actuators will grow at 4.8% CAGR during the assessment period and reaches USD 26,841.5 million by 2035. Such growth is boosted by the demand for automation of industrial operations and energy-efficient system demands, plus expansion of their applications in areas such as transport, mining, and offshore sectors. Pneumatic actuators are widely preferred due to its reliability, high precision, and cost-effectiveness in controlling valve dampers as well as any other process equipment.

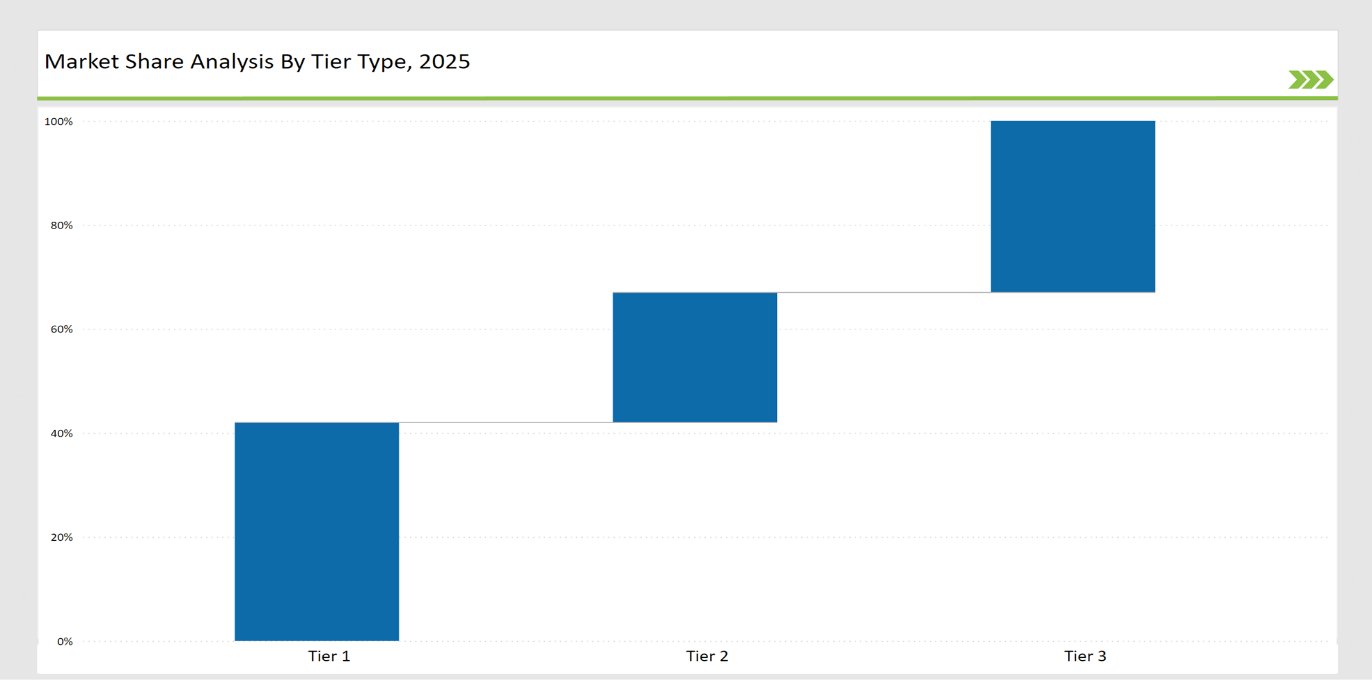

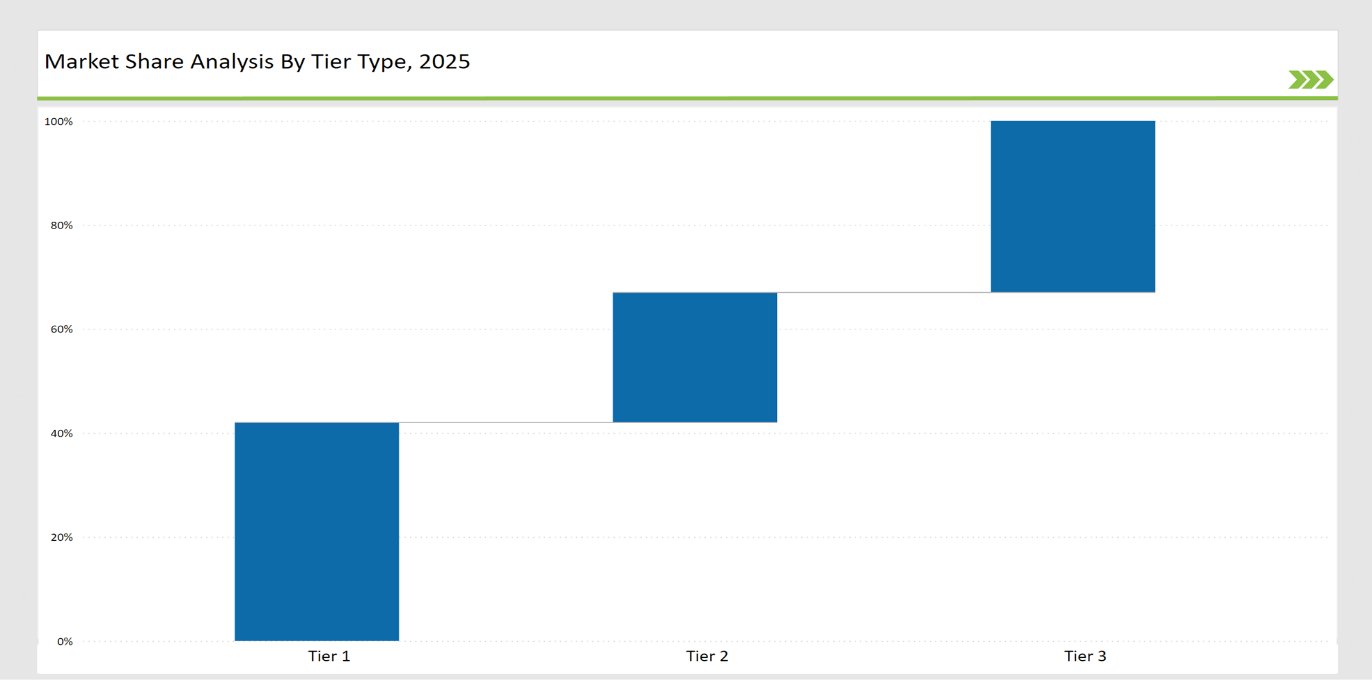

The market is moderately consolidated, with Tier 1 players such as Emerson Electric Co., Parker Hannifin, and Festo SE & Co. KG holding a combined global market share of 42%. They dominate through advanced pneumatic actuator solutions designed for industrial automation and energy-critical applications. Among operations, double-acting type pneumatic actuators have the highest market share at 55%, and in applications, industrial automation occupies 50% of the market share, as demand for effective process control systems continues to grow.

| Attribute |

Details |

| Projected Value by 2035 |

USD 26,841.5 million |

| CAGR during the period 2025 to 2035 |

4.8% |

Explore FMI!

Book a free demo

Industry Landscape

| Category |

Industry Share (%) |

| Top 3 Players (Emerson Electric Co., Parker Hannifin, Festo SE & Co. KG) |

42% |

| Next 2 of 5 Players (SMC Corporation, Rotork) |

25% |

| Rest of the Market |

33% |

The market is fairly consolidated, with global players influencing technological advancements and standardization while regional players compete on price and application-specific products.

Segmental Analysis

By Operation:

- Double Acting Type Pneumatic Actuator (55% Market Share): double acting actuators are preferred in most applications due to the better control and consistent force developed during the stroke, suitable for industries in automation and offshore applications. Festo SE & Co. KG is leading this market segment with wide durable and Customizable solutions.

- Spring Return Type Pneumatic Actuator: Spring return actuators are also used in safety-critical applications where they can revert to a fail-safe position in case air supply fails. Emerson Electric Co. deals with this segment, providing actuators designed for reliability in hazardous environments.

By Application:

- Industrial Automation (50% Market Share): The industrial automation segment leads the market due to the growth in pneumatic actuators for manufacturing, process industries, and robotics. Parker Hannifin and SMC Corporation specialize in providing energy-efficient solutions for automated systems.

- Transportation: Pneumatic actuators find extensive application in transportation systems with braking, door operations, and other control mechanisms. Festo SE & Co. KG takes the lead with lightweight, high-performance solutions in rail and automotive applications.

- Mining: In mining, pneumatic actuators are significant for controlling major equipment and providing operational efficiency at extreme conditions. Rotork specialises in ruggedized actuators for mining.

- Offshore: The offshore segment benefits from pneumatic actuators' reliability and resistance to harsh environmental conditions, such as high humidity and saltwater exposure. Emerson Electric Co. leads this segment with corrosion-resistant and explosion-proof solutions.

Who Shaped the Year?

In 2024, several companies significantly influenced the pneumatic actuator market:

- Emerson Electric Co.: Emerson released high-performance spring-return pneumatic actuators that find applications in safety-critical applications in offshore and industrial automation. The company strengthened it footprint in Asia-Pacific by collaborating with regional distributors.

- Parker Hannifin: Parker Hannifin unveiled energy-efficient double-acting pneumatic actuators for industries that manufacture and process. The company emphasized IoT-enabled solutions for predictive maintenance and better operational efficiencies.

- Festo SE & Co. KG: Festo created lightweight pneumatic actuators that were adapted to transportation products, such as rail systems and electric vehicles. The company further highlighted modular concepts for various demands of the industry.

- SMC Corporation: SMC added the following products: compact and cheap pneumatic actuators for industrial automation in low-capacity environments. The company also expanded the distribution network, especially in growing markets.

- Rotork: Rotork went for rugged pneumatic actuators for mining and introduced new product lines that have the ability to withstand extreme environments. The firm also invested its R&D funds in making more durable and highly performing actuators.

Key Highlights from the Forecast

- Double-Acting Actuators Lead Operations: Double-acting actuators play the lead in operations, accounting for 55% of all markets, as they offer versatility and better force control.

- Industrial Automation Dominates Applications: Industrial automation has the biggest market share at 50%, as actuators have begun to prevail in manufacturing and process control applications.

- IoT Integration Enhances Efficiency: IoT-based smart pneumatic actuators are in high demand these days as it allows for the real-time monitoring and predictive maintenance of these systems.

- Emerging Markets Drive Growth: Industrialization and infrastructure development in Asia-Pacific and the Middle East are driving the growth of markets.

Tier-Wise Industry Classification

| Tier |

Examples |

| Tier 1 |

Emerson Electric Co., Parker Hannifin, Festo SE & Co. KG |

| Tier 2 |

SMC Corporation, Rotork |

| Tier 3 |

Regional and niche players |

Market KPIs

Key performance indicators in the pneumatic actuator market include:

- Control Precision: Applications requiring high-precision control include industrial automation, transportation, etc.

- Durability and Environmental Resistance: Resistance to extreme environments is gaining favour with the onset of offshore applications and mining processes.

- Energy Efficiency: Energy-efficient actuators are gaining popularity in industries aiming to reduce operational costs and carbon emissions. Energy-friendly actuators have found acceptance within organizations looking at cutting costs while ensuring low-carbon footprint

- IoT-Enabled Monitoring: Monitoring actuators, which send information on its functioning in real-time and suggest when maintenance could be done will reshape the actuator market in the near future.

Key Company Initiatives

| Company |

Initiative |

| Emerson Electric Co. |

Launched advanced spring-return actuators for safety-critical applications and expanded in Asia-Pacific. |

| Parker Hannifin |

Launched energy-efficient double-acting actuators for process industries, focusing on IoT integration.. |

| Festo SE & Co. KG |

Developed modular pneumatic actuators for transportation systems and lightweight industrial applications. |

| SMC Corporation |

Expanded compact and affordable actuators targeting small-scale automation setups in emerging markets. |

| Rotork |

Focused on ruggedized actuators for mining and offshore applications, investing in durability enhancements.. |

Recommendations for Suppliers

- Expand Double-Acting Offerings: Focus on double-acting pneumatics for automation in industry and offshore applications, which are very versatile and efficient.

- Target Emerging Markets: Strengthen the regional distribution networks to capture the growth opportunities that exist in the Asia-Pacific region, Latin America, and the Middle East.

- Leverage IoT Integration Create smart pneumatic actuators that can predict the maintenance needs and cater to the high-demanding industries.

- Focus on Specialized Applications: Offer specific solutions for mining, transportation, and offshore sectors, where strength and reliability are paramount.

Future Roadmap

The pneumatic actuator market in the world is expected to grow steadily with a trend of increased adoption in industries with automation and energy-efficiency measures. Manufacturers need to focus on double-acting actuators for industrial automation while targeting niche applications like mining and offshore applications. Investments into IoT-enabled solutions and energy-efficient designs would be critical to ensuring competitiveness. Strategic partnerships and expansion in the emerging markets would define further the market prospect in favour of the manufacturers who could reach out to emerging customer needs.

Frequently Asked Questions

Which Companies hold significant share in the pneumatic actuator market?

Emerson Electric Co., Parker Hannifin, Festo SE & Co. KG command about 42% share in the overall market.

Which is the leading product segment in pneumatic actuator market?

Actuators Scotch Yoke Pneumatic comprise nearly 35% of the overall market.

How much share does regional and domestic companies hold in the market?

Regional and domestic companies hold nearly 35% of the overall market.

How is the market concentration assessed in the pneumatic actuator market?

Market is fairly consolidated, representing top 10 players commanding significant share in the market.

Which application sector offering significant growth potential to market players?

Industrial Automation application offering significant growth prospects to market players.