The plastic caulk tube market is growing at a rapid pace as industries focus on durable, lightweight, and eco-friendly packaging solutions. Manufacturers are innovating with high-strength plastics, sustainable materials, and user-friendly designs to meet the increasing demand across construction, automotive, and home improvement sectors. The market consists of Tier 1, Tier 2, and Tier 3 players, each contributing to the evolving competitive landscape.

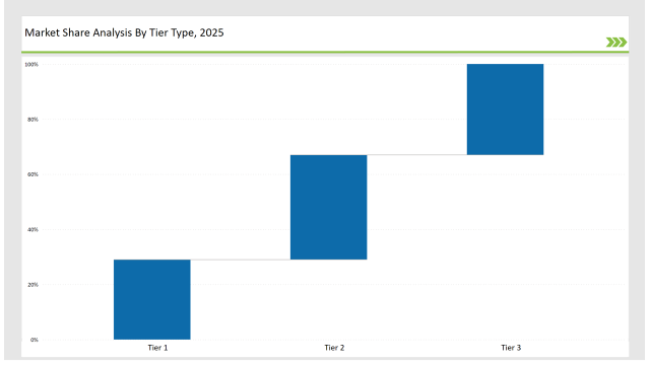

Tier 1 companies such as Berry Global, Sonoco Products, and Silgan Holdings account for nearly 29% market share. The strength of these companies is large-scale production, high investments in R&D, and an extensive network of distribution globally.

The remaining 38% market share is of Tier 2 players, among which Plastipak, Auber Packaging, and Comar feature prominently. These players are working on reducing costs while maintaining high-performance plastic caulk tubes to serve mid-scale industrial and commercial applications while incessantly developing new packaging technologies.

Tier 3 manufacturers and niche brands such as Pano Cap, Andler Packaging, and Cospack America represent 33% of the market. These players focus on customized tube designs, sustainable alternatives, and flexible, region-specific manufacturing capabilities.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Berry Global, Sonoco Products, Silgan Holdings) | 14% |

| Rest of Top 5 (Plastipak, Auber Packaging) | 9% |

| Next 5 of Top 10 (Comar, Pano Cap, Andler Packaging, Cospack America, Greiner Packaging) | 6% |

The Plastic Caulk Tube Market serves key industries, including:

To address industry demands, manufacturers offer solutions such as:

Sustainability remains a core focus, with significant investments in biodegradable plastics, lightweight packaging innovations, and energy-efficient manufacturing processes.

Leading manufacturers are setting new industry standards with enhanced plastic compositions, AI-driven production efficiencies, and smart packaging innovations. Companies are improving tube durability, developing recyclable materials, and optimizing tube design for better usability. Additionally, automation is streamlining manufacturing processes, reducing costs, and enhancing quality control. Notable developments include:

Year-on-Year Leaders

Technology suppliers in the Plastic Caulk Tube Market must prioritize sustainability, user-friendly packaging, and efficiency improvements to stay competitive. Key investment areas include:

Check Free Sample Report & Save 40%!

Select your niche segments and personalize your insights for smart savings. Cut costs now!

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Berry Global, Sonoco Products, Silgan Holdings |

| Tier 2 | Plastipak, Auber Packaging, Comar |

| Tier 3 | Pano Cap, Andler Packaging, Cospack America, Greiner Packaging |

| Manufacturer | Latest Developments |

|---|---|

| Berry Global | Launched fully recyclable plastic caulk tubes (January 2024). |

| Sonoco Products | Developed lightweight, impact-resistant tubes (March 2024). |

| Silgan Holdings | Expanded bio-based plastic alternative tube production (April 2024). |

| Plastipak | Innovated with high-strength, low-waste tube designs (May 2024). |

| Auber Packaging | Released ergonomic caulk tube designs for ease of use (July 2024). |

Leading companies in the Plastic Caulk Tube Market emphasize sustainability, efficiency, and innovation.

The Plastic Caulk Tube Market is evolving with sustainable materials, smart manufacturing techniques, and improved consumer convenience. Companies are integrating biodegradable alternatives, AI-powered production lines, and smart dispensing features. Future trends include enhanced tube recyclability, waste-reducing production methods, and wider adoption of eco-friendly packaging solutions.

Leading manufacturers include Berry Global, Sonoco Products, and Silgan Holdings.

The top 10 players hold approximately 29% of the global market.

Sustainability, automation, and smart dispensing innovations.

By developing biodegradable plastics, reducing material waste, and increasing recyclability.

Enhancing usability, strength, and efficiency in manufacturing.

Explore Packaging Formats Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.