The global pallet truck market is projected to witness steady growth between 2025 and 2035 due to the continued growth of e-commerce over the coming years, increasing warehousing activities, and growing adoption of material handling solutions. The expanding demand for efficient and safe cargo handling in warehouses and distribution centers is driving the adoption of pallet trucks due to their dependability, affordability, and versatility. Electric and semi-electric pallet trucks- Key industries like retail, manufacturing, and logistics are all investing in upgraded material handling equipment to improve productivity and minimize downtime. Renew and Resilience Because data sceptre is used for many purposes, such as their reliability. Further elevating the market’s growth prospects are enhanced durability and better load-handling capacity, which are integrated with warehouse management systems.

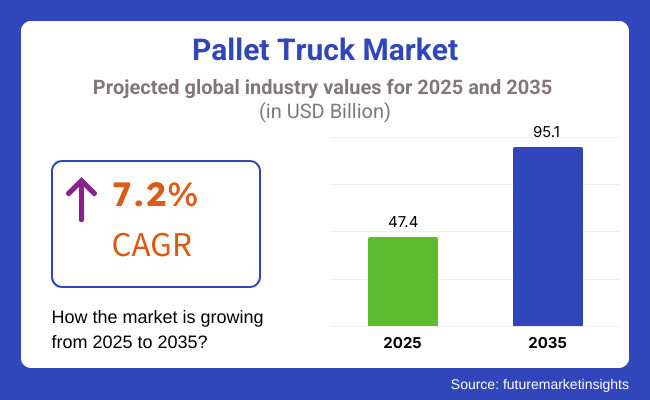

The projected growth rate of 7.2% CAGR between 2025 and 2035 for the market indicates the rising demand for electric and automated pallet trucks around various sectors. Another growth factor is ongoing investment in smart warehousing, and AGVs employ smart pallet trucks to increase their throughput and inventory management capabilities. Key Insights & Findings from the Report: Improved material handling technologies coupled with the rising adoption of electric models in both developed and emerging markets support the positive market outlook. Moreover, the increasing number of third-party logistics (3PL) providers and growing cross-border trade are among the factors expected to facilitate the demand for pallet trucks with enhanced efficiency, reliability, and performance.

Explore FMI!

Book a free demo

Pallet truck demand in North America continues to dominate by volume with a strong logistics foundation along with an established e-commerce network. Moreover, this growth is driven by factors such as rising investment from various companies in the United States and Canada in warehouse automation and advanced material handling equipment, including electric and semi-electric pallet trucks in both countries. As industries look for ways to cut their carbon emissions, the move toward cleaner, greener alternatives like lithium ion-powered pallet trucks is being prioritized. Beyond the growing e-commerce, the increased importance of cold chain logistics is boosting demand for specialized pallet trucks that can handle temperature-critical goods. In general, due to their reliance on advanced technology and their ability to manage supply chains effectively, North America is one of the prominent contributors to market growth.

The European pallet truck market is dominated by strict environmental policies, large warehousing networks, and a strong emphasis on workplace safety. Germany, France, and the UK are leading the shift from conventional internal combustion engine (ICE) trucks to electric-powered trucks. Meeting rigorous standards imposed by government incentives and EU directives for lowering carbon emissions has forced manufacturers to get to work producing environmentally friendly pallet trucks. Moreover, the use of autonomous and remotely controlled pallet trucks is rapidly becoming a trend among European companies focused on operational efficiency, worker safety, and direct compatibility with intelligent warehouse management systems. With growing demand for electric and hybrid models, as well as technological advances, Europe is a vibrant space for market development.

The pallet truck market in the Asia-Pacific region is expected to grow at the fastest pace as a result of industrialization, urbanization, and the penetration of e-commerce. As major manufacturing centers, China and India are experiencing a boom in warehousing and logistics. Large-scale distribution centres and online retail giants are employing more electric pallet trucks and semi-automated solutions, particularly in these countries. Further, Japan and South Korea are at the forefront of the innovation path for technology solutions like autonomous pallet trucks and intelligent material handling. The growing focus on automation in the region, coupled with the government efforts to promote sustainable and power-efficient equipment, will be a boost to market growth. Competitive pricing, product variety availability, and ongoing infrastructure expansion in the Asia-Pacific region are likely to sustain the strong growth momentum.

Challenges

Market challenges such as high initial investment costs, limited acceptance of advanced models in cost-sensitive markets, and the requirement for regular maintenance and repairs restrict the growth of the pallet truck market. Electric pallet trucks and autonomous models certainly have their benefits in the long run, but the high upfront costs may put smaller businesses off purchasing these models. Furthermore, it can cause operational breakdowns and workplace accidents due to safety issues caused by the use of outdated or improperly maintained pallet trucks. A weak infrastructure and lack of trained persons may make the penetration further difficult in the developing regions. Moreover, changing raw material prices and disruptions in the supply chain exacerbated by global economic uncertainties become key challenges for manufacturers and end-users alike.

Opportunities

Challenges may persist with the distribution of pallet trucks in vulnerable regions to unintended global displacement. Another prominent growth opportunity comes from the increasing demand for automated guided vehicles (AGVs) and autonomous pallet trucks in scale boxes. Enhanced battery technologies such as lithium-ion power systems offer extended run times, rapid charging, and reduced maintenance requirements, making electric pallet trucks more appealing to an even broader customer base. In addition, the increasing emphasis on sustainability and green warehousing operations is creating a demand for energy-efficient and recyclable pallet trucks as global supply chains continue to integrate. These untapped markets across Africa, the Middle East, and Latin America present opportunities for expansion. Finally, IoT and warehouse management systems based on advanced technology are seamlessly integrating pallet trucks into smart warehousing ecosystems that enhance overall productivity and efficiency.

From 2020 to 2024, the pallet truck market experienced remarkable expansion, driven by the expansion of e-commerce, warehouse automation, and supply chain optimization. The growth in sales was largely driven by the growth of distribution centers, 3PL, and the increasing material handling needs in the industries. Market dynamics were impacted by variables such as supply chain delays, fluctuations in raw material costs, and availability of workforce. Companies responded with the adoption of semi-automated pallet trucks, investing in fleet management solutions, and redesigning ergo for greater worker safety and performance.

From 2025 to 2035, the pallet truck market is expected to evolve with Artificial Intelligence (AI) and IoT-enabled tracking, in addition to the complete autonomous material handling system replacing it. The companies also claim that the use of lithium-ion battery technology, sustainability initiatives, and advanced fleet telematics will improve operational efficiency. The industry will aim for energy-efficient, low-maintenance, smart-connected pallet trucks that meet the demand for carbon-neutral logistics solutions through overall automation in the industry.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Compliance to occupational safety standards, emission regulations, and ergonomic guidelines. |

| Warehouse and Logistics Trends | The growth of e-commerce and 3PL activities increased demand for hand and semi-automatic pallet trucks. |

| Industry Adoption | Shift towards electric and lithium-ion-driven pallet trucks for improved efficiency and sustainability. |

| Power and Battery Technology | Use of lead-acid batteries in electric pallet trucks, with growing application of lithium-ion variants. |

| Market Competition | Presence of traditional pallet truck producers and the advent of automated guided vehicle (AGV) solutions. |

| Market Growth Drivers | Growing requirements from warehousing, retail, and manufacturing industries for efficient material handling. |

| Sustainability and Energy Efficiency | The initial shift towards eco-friendly electric pallet trucks and energy-efficient fleet management. |

| Integration of Smart Tracking | Limited adoption of RFID and GPS-based fleet tracking solutions. |

| Advancements in Material Handling Solutions | Development of compact, high-load capacity pallet trucks with improved maneuverability. |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Stricter carbon emission regulations, mandatory use of energy-efficient electric pallet trucks, and increased focus on automation safety standards. |

| Warehouse and Logistics Trends | Expansion of fully automated warehouses, AI-driven inventory management, and autonomous pallet trucks in logistics operations. |

| Industry Adoption | Widespread adoption of IoT-enabled, AI-driven smart pallet trucks with real-time tracking and automated route optimization. |

| Power and Battery Technology | Dominance of lithium-ion and hydrogen fuel cell-powered pallet trucks, offering longer runtimes and faster charging. |

| Market Competition | The emergence of AI-powered robotic pallet trucks increased competition from autonomous logistics technology providers. |

| Market Growth Drivers | Surge in demand for autonomous material handling solutions, robotics integration, and sustainability-driven innovations. |

| Sustainability and Energy Efficiency | Large-scale adoption of carbon-neutral material handling equipment powered by renewable energy sources. |

| Integration of Smart Tracking | Expansion of AI-driven predictive maintenance, cloud-based fleet management, and real-time telematics integration. |

| Advancements in Material Handling Solutions | Evolution of fully autonomous, AI-assisted material transport systems for optimized warehouse and logistics operations. |

The USA is one of the leading pallet truck markets globally, with the growth of logistics, warehousing, and retail industries in particular driving demand. Market growth is driven by the rising demand for material handling solutions from the manufacturing industry and e-commerce fulfillment centers. Further, innovations in electric and automated pallet trolleys, as well as the installation of IoT-based tracking systems, are altering warehouse processes. The adoption of pallet trucks across different industries is further strengthened by the presence of diverse logistical players and distribution centers. Salvaging, storing, and recycling resources for sustainable material handling solutions are also fuelling the demand for battery-powered and hydrogen fuel cell pallet trucks. Moreover, the growing trend of Omni channel retailing has created a dire need for enhanced warehouse efficiency, which is pushing the adoption of automated pallet trucks integrated with AI and machine learning.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 7.5% |

Growing automated warehouses, increasing online retail penetration, and rapid growth of the food & beverage segment are the key factors fuelling demand for pallet trucks in the UK market. The increasing use of electric and smart pallet trucks, coupled with the integration of AI-driven logistics solutions, is propelling market adoption. Moreover, government regulations and initiatives for sustainable supply chains and reduced carbon emissions are further encouraging businesses to invest in eco-friendly pallet truck solutions. Also playing a prominent role in warehouse transformation is the growth of investment in robotics and automation throughout logistics hubs. In addition, due to an increasing emphasis on minimizing workplace injuries and an evolution in ergonomically engineered handling equipment, the country is moving towards the usage of advanced pallet trucks with superior safety features.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 6.9% |

Germany, France, and Italy have dominated the European pallet truck market, and the growth of logistics, retail, and automotive sectors will help retain their position in this market. Due to the focus on automation and green energy solutions in the European Union, there is a progressive switch from manual to electric and semi-automated pallet trucks. Increasing investments in e-commerce promotions by businesses to capture a larger segment of customers have led to a rising market demand for smart pallet trucks with predictive maintenance and real-time data tracking, which is set to boost the expansion of the smart pallet truck market. New initiatives focusing on circular economy principles have also created a demand for sustainable and durable pallet trucks consisting of recyclable components. Moreover, the impetus to digitize warehouses, as well as the introduction of robotic palletization in manufacturing and distribution industries, are streamlining industrial processes and minimizing the reliance on manual labor. European companies are investing in high-performance pallet trucks optimized for heavy loads and extended working hours, with their growth driven by increasing volume through cross-border trade within the EU.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union | 7.1% |

Japan is at the forefront of robotics, automation, and high-tech manufacturing, and this is contributing to the expansion of Japan's pallet truck market. This is assisting in driving the growth of advanced pallet trucks, as businesses in every industry, from automotive to electronics and from pharmaceuticals to warehouses, are looking more and more for materials-handling solutions that can handle these kinds of issues. Warehouse automation with the aid of compact electric pallet trucks & AGVs (Automated Guided Vehicles) is a trend transforming the market. This drive toward labour minimization and operational efficiency is also compelling businesses to invest in automated pallet truck solutions. Japan's high population density, along with limited warehouse or storage space, is increasing demand for compact and multi-functional pallet trucks, which enhance space utilization. Further, there is an increase in demand for autonomous material handling systems with a combination of AI, robotics, and IoT for operation in the country’s logistics industry.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 7.0% |

The South Korean pallet truck market is expanding owing to the growth of e-commerce, logistics, and smart warehouses in the countries. Leading manufacturing companies are implementing AI-based material handling solutions, which are fuelling the demand for electric and autonomous pallet trucks. The second generation of pallet trucks, equipped with energy-efficient and AI-driven technologies, is being used in various sectors due to government investments in industrial automation and smart logistics hubs, which is driving innovation and adoption. The booming semiconductor and electronics sectors in the country necessitate high-precision logistics solutions, leading to further adoption of advanced material handling equipment. Additionally, South Korea's investment in smart city projects is propelling the development of intelligent warehousing solutions, such as self-navigating pallet trucks with LiDAR and real-time data analytics. Warehousing solutions like self-guiding pallet trucks equipped with LiDAR and real-time data analysis.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 7.3% |

The manual and electric pallet truck segments maintain a leading share in the pallet truck industry as businesses continually look for cost-effective, efficient, and scalable material handling options. These pallet trucks are a key driver of warehouse logistics efficiency, operational performance, and elimination of manual labor strain, hence a must-have for manufacturing plants, distribution warehouses, retail warehouses, and logistics firms.

Manual Pallet Trucks Remain Essential for Cost-Effective and Flexible Operations

Affordable, easy to use, and low maintenance machines; manual pallet trucks are still generally used. These pallet trucks are used in small-scale warehouses, small retail stores, and other small distribution centers to transport materials over short distances. Manual pallet trucks don't need battery charging or fuel like powered alternatives do so they are perfect for businesses where their handling needs are limited and budget is an issue.

Accordingly, the greater demand for durable, ergonomic, and lightweight manual pallet trucks continues to drive the growth of the market, especially as several industries need flexibility in confined storage areas. For instance, manufacturers are focusing on investing more in innovations, including hydraulic lifting mechanisms, stronger fork designs, and wheels that make it easier and more efficient to move.

While they offer cost savings and operational simplicity, manual pallet trucks suffer from issues like operator fatigue, limited weight capacity, and decreasing efficiency in large-scale warehouses. But innovations such as ergonomic handle designs, load stability improvements, and AI-enabled load monitoring systems are pushing efficiency, safety, and ease of operations, thus ensuring market demand for hand-operated pallet trucks will continue across all geographies.

Electric pallet trucks have made a considerable mark on sectors with high-volume logistics, providing an uninterrupted material lift experience that reduces the strain of manual labour whilst maximising productivity in the warehouse. It is not an ordinary manual pallet truck; these manual pallet trucks are electrically powered by a rechargeable battery, allowing for higher speed transportation of goods while even reducing the effort for a worker to move them.

A notable increase in the number of e-commerce fulfillment centers, high-volume distribution centers for small and medium-sized businesses (SMEs), and automated warehouses has fostered the rapid adoption of electric pallet trucks. Research shows that more than 60% of high-volume warehouses are now choosing electric pallet trucks as top priorities to increase the efficiency of the operation, reducing any downtime and maximizing supply chain execution.

The increased market demand for lithium-ion-powered electric pallet trucks, enhanced with rapid charging, extended operational hours and AI-integrated fleet management, has bolstered the market's potential for better adaptability to industrial environment and improved performance.

While they offer benefits like faster operations, automation, and less reliance on labour, electric pallet truck models come with disadvantages like upfront expense, battery maintenance, and less efficiency in outdoor and uneven surface applications. However, evolving technologies related to energy-efficient batteries, fast-growing lightweight solutions, and AI-led predictive maintenance will escalate operational sustainability and ensure cost-effectiveness and reliability, which will sustain market growth for electric pallet trucks globally.

The standard and weighing pallet truck markets account for a strong market share because companies value efficiency, precision, and dependability in their material handling processes. The pallet truck types serve to meet a wide variety of industries, including retail and warehousing, food processing, and manufacturing.

Standard Pallet Trucks Maintain Market Leadership in Industrial Applications

Standard pallet trucks will continue to take over the market next due to their great versatility, durability, and easy operation. They are commonly used in manufacturing plants, logistics centers, and retail supply chains to move heavy loads more efficiently. While there are certainly more advanced pallet trucks that have a specific expert application, the standard pallet truck is the all-around ideal solution in most material handling scenarios, providing the best balance between performance and cost.

High-quality, reinforced, and ergonomically designed standard pallet trucks have increased demand in high-traffic environments, which has propelled market growth significantly. To do this, manufacturers are concentrating on innovations like corrosion-resistant materials, improved maneuverability of wheels and increased stability of loads.

Standard pallet trucks, though, much-needed for their sturdiness and reliability, do come with unforeseen obstacles, including poor adaptability to specialized industrial applications, lowered efficiency in precision-biased sectors, and unsatisfactory operations in automated warehouses. Nonetheless, innovations in the industry, such as AI-enabled load-tracking, smart pallet-compatible features, and ergonomic adjustments, are making pallet trucks more usable, thus increasing their use amongst players across the logistics industry, leading to steady demand for standard pallet trucks around the world.

Weighing Pallet Trucks Gain Popularity as Precision and Efficiency Become Key Priorities

Various industries such as logistics, agriculture, and food processing have adopted weighing pallet trucks due to the specific need for close measures of load. Standard pallet trucks do not typically have this feature and weigh the cargo visually as operators often rely on their experience to assess the weight capacity the equipment can support, while weighing models come equipped with built-in scales to allow operators to measure cargo weight with precision in real-time, ensuring compliance with load capacity regulations; these systems are also beneficial for inventory management and improvement of operation processes.

To gain a better understanding of the market, primarily due to the increasing demand for integrated weighing and another weighing solution and the development of advanced systems with digital display panels, wireless connectivity, and automated data logging. Research suggests that more than 55% of warehouses are already handling perishable goods or bulk and consequently make use of weighing pallet trucks able to monitor the weight of goods either inline or on dispatch, ensuring both compliance with regulations and optimization of supply chain management.

Weighing pallet trucks has its benefits with respect to accuracy, efficiency, and regulatory compliance. Still, it also faces drawbacks in terms of higher fees, additional maintenance requirements, and potential calibration issues. Nonetheless, recent innovations in the Internet of Things (IoT) enabled weight monitoring, machine-driven load distribution analysis, and real-time digital inventory tracking are all contributing to improved accuracy, automation, and reliability, assuring sustainable growth in the global market for weighing pallet trucks.

The growing demand for efficient material handling solutions, the increasing need for warehouse automation, and the growing logistics market are a few of the factors that are driving the pallet truck market. Warehouse operations is challenged when it comes to minimizing labour costs and maximizing productivity, which is where electric and manual pallet trucks have an important role to play. Taiwan-based manufacturers offer some of the highest quality trucks in the industry as the country's substance and topography demand ergonomic designs.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Toyota Material Handling | 12-16% |

| KION Group (Linde, STILL) | 10-14% |

| Jungheinrich AG | 8-12% |

| Hyster-Yale Materials Handling | 6-10% |

| Crown Equipment Corporation | 4-8% |

| Other Companies (combined) | 45-55% |

Key Company Offerings and Activities

| Company Name | Key Offerings/Activities |

|---|---|

| Toyota Material Handling | Offers advanced electric pallet trucks with IoT integration and enhanced safety features. |

| KION Group (Linde, STILL) | Designs intelligent pallet trucks with automation and energy-efficient solutions. |

| Jungheinrich AG | Offers lithium-ion powered pallet trucks with ergonomic designs for efficient warehouse operations. |

| Hyster-Yale Materials Handling | Materials Handling Experts in rugged manual and electric pallet trucks with industrial and retail uses. |

| Crown Equipment Corporation | Designs connectivity-based pallet trucks with real-time fleet monitoring. |

Toyota Material Handling (12-16%)

Toyota leads the pallet truck industry with cutting-edge electric models, IoT-enabled fleet solutions, and high-efficiency material handling technology.

KION Group (Linde, STILL) (10-14%)

KION Group provides automation-instrumented pallet truck solutions, reducing costs of operations and enhancing efficiency in warehouse management.

Jungheinrich AG (8-12%)

Jungheinrich enhances logistics productivity with lithium-ion-powered pallet trucks, ensuring sustainability and ergonomic operation.

Hyster-Yale Materials Handling (6-10%)

Hyster-Yale provides versatile manual and electric pallet trucks designed for durability, safety, and heavy-duty applications.

Crown Equipment Corporation (4-8)

Crown combines connectivity solutions, providing fleet tracking and real-time analytics to enhance material handling efficiency.

Other Key Players (45-55% Combined)

Numerous companies contribute to the pallet truck market by developing innovative, cost-effective, and technologically advanced solutions. These include:

The pallet truck market continues to grow with the advancement of automation, connectivity, and sustainable power solutions, driving efficiency across warehouses and industrial supply chains.

The overall market size for Pallet Truck Market was USD 47.4 Billion in 2025.

The Pallet Truck Market expected to reach USD 95.1 Billion in 2035.

The demand for the pallet truck market will be driven by the rapid expansion of e-commerce, increasing warehouse automation, growing logistics and supply chain activities, and the rising need for efficient material handling solutions. Additionally, advancements in electric and smart pallet trucks will further boost market growth during the forecast period.

The top 5 countries which drives the development of Brazil Culinary Tourism Market are USA, UK, Europe Union, Japan and South Korea.

Electric Pallet Trucks Market drives growth to command significant share over the assessment period.

Power Tool Gears Market - Growth & Demand 2025 to 2035

Radial Drilling Machine Market Growth & Demand 2025 to 2035

External Combustion Engine Market Growth & Demand 2025 to 2035

Motor Winding Repair Service Market Growth - Trends & Forecast 2025 to 2035

Industrial Linear Accelerator Market Growth & Demand 2025 to 2035

Industrial Coupling Market Growth - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.