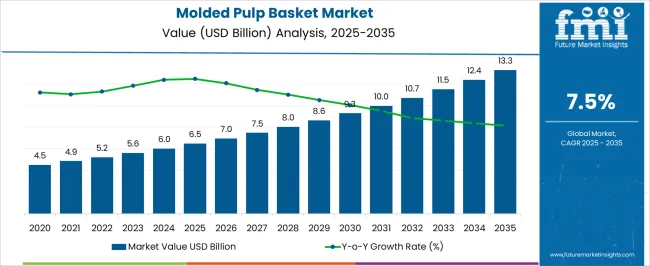

The Molded Pulp Basket Market is estimated to be valued at USD 6.5 billion in 2025 and is projected to reach USD 13.3 billion by 2035, registering a compound annual growth rate (CAGR) of 7.5% over the forecast period.

| Metric | Value |

|---|---|

| Molded Pulp Basket Market Estimated Value in (2025 E) | USD 6.5 billion |

| Molded Pulp Basket Market Forecast Value in (2035 F) | USD 13.3 billion |

| Forecast CAGR (2025 to 2035) | 7.5% |

The molded pulp basket market is witnessing considerable expansion driven by the global shift toward eco-friendly and compostable packaging solutions. Increasing restrictions on single-use plastics and mounting pressure from environmental regulatory frameworks have accelerated the demand for biodegradable alternatives such as molded pulp. Industries such as food and agriculture are embracing molded pulp baskets for their protective structure, recyclability, and low environmental impact.

Manufacturers are enhancing pulp molding technologies to achieve higher precision and strength while minimizing material wastage. Additionally, consumer preference for sustainable packaging in fresh produce, bakery, and beverage categories is driving greater penetration of molded pulp baskets across retail and distribution networks.

As governments worldwide implement circular economy models and retailers commit to plastic reduction pledges, molded pulp packaging is expected to become a mainstream solution. Continued innovation in raw material sourcing, molding equipment, and surface finishing is likely to open up new applications and improve adoption in high-volume, automated production environments.

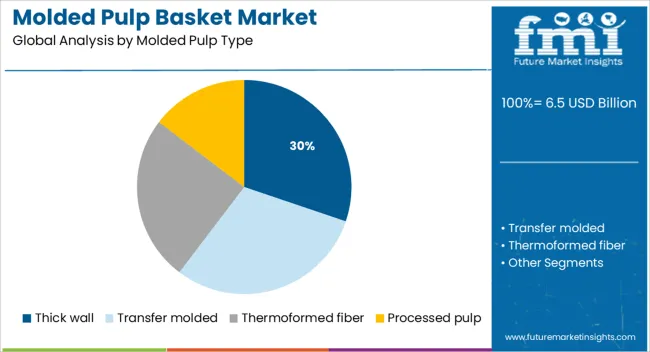

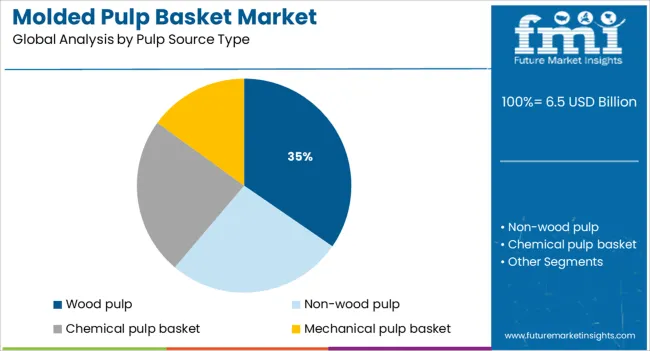

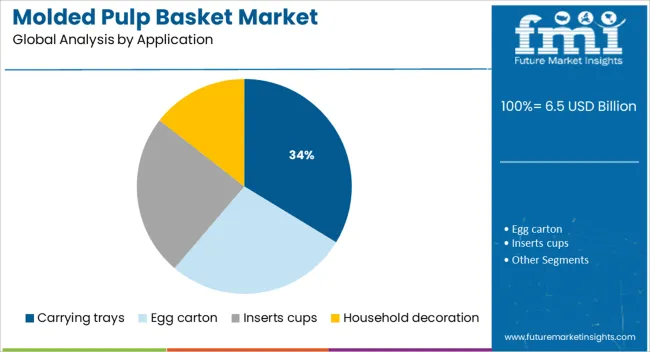

The market is segmented by Molded Pulp Type, Pulp Source Type, Application, and End Users and region. By Molded Pulp Type, the market is divided into Thick wall, Transfer molded, Thermoformed fiber, and Processed pulp. In terms of Pulp Source Type, the market is classified into Wood pulp, Non-wood pulp, Chemical pulp basket, and Mechanical pulp basket. Based on Application, the market is segmented into Carrying trays, Egg carton, Inserts cups, and Household decoration. By End Users, the market is divided into Food and beverage, Medical, Cosmetics and beauty products, and Logistics industry. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The thick wall segment is anticipated to account for 30.2% of the molded pulp basket market revenue in 2025, establishing it as the leading molded pulp type. Its dominance is driven by its structural integrity, thermal insulation, and shock resistance, making it ideal for packaging and transporting heavy or delicate goods.

Thick wall pulp baskets are typically manufactured using a lower drying temperature and longer pressing cycle, which results in a denser and more durable product. This format is particularly favored in produce handling and industrial packaging due to its strength and capacity to protect goods during extended transit.

The segment’s growth is further supported by the compatibility of thick wall molding with renewable pulp materials and closed-loop water recycling systems in manufacturing. As sustainability initiatives and packaging durability requirements intersect, the thick wall segment continues to gain preference across multiple end-use sectors.

Wood pulp is projected to contribute 34.6% of total market revenue by 2025 within the pulp source category, making it the leading material input. Its leadership is attributed to the abundant global availability of softwood and hardwood fibers, which provide strong bonding and structural consistency required for molded pulp baskets.

Wood pulp offers optimal fiber length and composition for forming rigid, resilient packaging while remaining cost-effective and easily processed through conventional pulping methods. Furthermore, certification standards such as FSC and PEFC are enabling manufacturers to align wood pulp sourcing with environmental compliance and traceability demands.

Investments in sustainable forestry practices and advanced pulping techniques have improved the resource efficiency of wood pulp utilization. These factors combined with the versatility of wood pulp in creating both basic and premium basket formats have contributed to its dominant share in the molded pulp basket market.

The carrying trays application segment is expected to represent 33.7% of molded pulp basket market revenue in 2025, ranking it as the top application. This leading position stems from the segment’s alignment with logistics efficiency, shelf display requirements, and consumer convenience.

Carrying trays are widely used across fresh produce, eggs, beverages, and confectionery items to provide structure, cushioning, and stackability. Their lightweight nature and low carbon footprint have made them the preferred choice for retailers and distribution centers transitioning away from plastic-based crates.

Additionally, molded pulp trays can be customized with partitioning and reinforcement to support various shapes and weights, enhancing their functionality in both retail-ready and industrial packaging environments. The rising demand for recyclable and compostable secondary packaging formats further reinforces the strong positioning of carrying trays within the molded pulp basket market.

Molded pulp products are made from cellulose fiber. Molded pulp baskets are used as a protective packaging for many products in food and beverage. Molded pulp basket has properties such as high strength, durability and low cost. Molded pulp baskets are recyclable, biodegradable. Sustainable and reduces input and disposal costs compared to other petroleum-based materials.

The applications of molded pulp basket includes egg cartons, packaging in logistics, carrying trays and for the decorating purposes in the households. Molded pulp basket are primarily used for the packaging of manufactured products or for food related carriers, such as food containers and serving trays.

Due to increasing number of end users in this market, there is slight increase for the demand in the molded pulp basket market. Globally, the molded pulp basket market in the Northern American and Western European region is likely to grow gradually in the forecast period.

With the increasing urbanization and consciousness for better packaging and awareness towards environment among the people are the leading factors for the growth of molded pulp basket market globally. Molded pulp basket are generally made from recycled newspapers that makes it eco-friendly.

Molded pulp basket used for packaging not only protects the material but also prevents from rupture during transportation across the supply chain. As molded pulp baskets are totally renewable and bio degradable in nature which makes it more popular than its alternatives.

Due to the properties like high strength, durability and cost efficiency and eco-friendliness, the molded pulp baskets can hamper the plastic industry in the market.

In the recent years, consumers are seeking sustainable packaging to the extent that it affects the choices that plays important role in the escalation of molded pulp baskets market. With the technological developments the molded pulp basket designs are more sturdy and effective.

The growth of e-commerce will create a demand for standardized packaging sizes which is likely to escalate the demand for molded pulp baskets market. Most of the manufacturing companies focus on the recyclability rather than sustainability of the molded pulp basket which can affect the growth of market. Also the stringent government regulation across the globe can affect the market of molded pulp baskets.

The regions such as Middle East and Africa, Northern Africa, GCC countries are likely to incline towards the molded pulp basket market. In the Asia Pacific regions the molded pulp basket industry proved to be dominant throughout the forecast period. The Western and Eastern European molded pulp basket market account for a significant market share in the European packaging market.

Some of the global key players in the molded pulp basket market are as follows:

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry exp

erts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Global molded pulp basket market can be segmented on the basis of molded pulp type, pulp source type, applications, end users and regions.

The global molded pulp basket market is estimated to be valued at USD 6.5 billion in 2025.

The market size for the molded pulp basket market is projected to reach USD 13.3 billion by 2035.

The molded pulp basket market is expected to grow at a 7.5% CAGR between 2025 and 2035.

The key product types in molded pulp basket market are thick wall, transfer molded, thermoformed fiber and processed pulp.

In terms of pulp source type, wood pulp segment to command 34.6% share in the molded pulp basket market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Breakdown of the Molded Pulp Basket Industry

Molded Fiber Bowl Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded FRP Grating Market Size and Share Forecast Outlook 2025 to 2035

Molded Foam Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Cup Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Wine Packs Market Size and Share Forecast Outlook 2025 to 2035

Molded Underfill Material Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber End Caps Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Containers Market Size and Share Forecast Outlook 2025 to 2035

Molded Wood Pallets Market Analysis - Size, Share & Forecast 2025-2035

Competitive Overview of Molded Wood Pallets Market Share

Molded Fiber Tray Market Trends – Growth & Forecast 2024-2034

Molded Case Circuit Breaker (MCCB) Market Growth – Trends & Forecast 2023-2033

Molded Interconnect Devices (MID) Market

Molded Pulp Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Pulp Packaging Machines Market Analysis - Growth & Forecast 2025 to 2035

Molded Fiber Pulp Packaging Industry Analysis in Australia and New Zealand Forecast Outlook 2025 to 2035

Molded Fiber Pulp Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Cap Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA