This lubricant package industry is continuously innovating under factors like sustainability, durability, and efficiency. The manufacturers in the automotive, industrial, and marine sectors are increasingly producing environmentally friendly, leak-proof, and high-barrier solutions across their respective categories according to their need. Smart packaging, tamper-proof designs, lightweight materials, and other forms of product safety and regulatory compliance are the priorities of brands.

Thus, various manufacturers such as high-performance plastic resins, biodegradable materials and smart tracking technologies have taken up the course of product integrity enhancement measures. This portion of the industry is also shifting to more recyclable HDPE containers, flexible pouches, and RFID-enabled caps for global transparency and anti-counterfeiting.

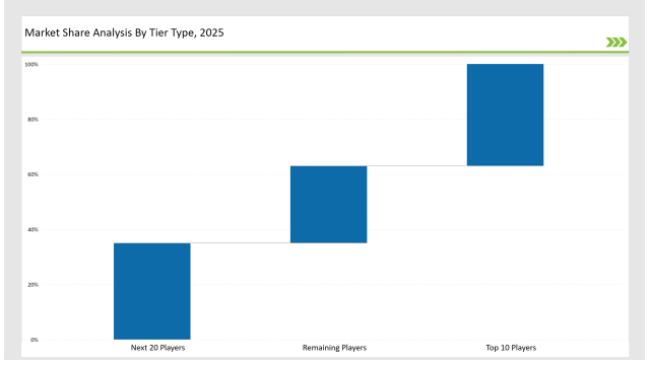

They control 37% of the market along with Tier 1 companies like Berry Global, Greif Inc and Mauser Packaging Solutions because of their leadership in high-performance lubricant containers, extensive distribution networks and commitment towards sustainability. Cost-effective light-weight and innovative lubricant packaging solutions are provided by Tier 2 companies like Mold-Tek Packaging, Scholle IPN and Balmer Lawrie and these companies capture 35% of the market.

This Tier 3 is composed of regional and niche players that also specializes in smart packaging, biodegradable lubricant containers, and custom design solutions. They hold an important 28 % of the market. These companies promote localizing production with sustainable ecological and technologically advanced dispensing technologies packaging.

Explore FMI!

Book a free demo

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Berry Global, Greif Inc., Mauser Packaging Solutions) | 18% |

| Rest of Top 5 (Mold-Tek Packaging, Scholle IPN) | 11% |

| Next 5 of Top 10 (Balmer Lawrie, Time Technoplast, CDF Corporation, Glenroy, SIG Combibloc) | 8% |

The lubricant packaging industry serves multiple sectors where product protection, dispensing efficiency, and sustainability are essential. Companies are developing advanced packaging solutions to enhance usability and reduce waste.

Manufacturers are optimizing lubricant packaging with innovative materials, smart technology, and sustainability-driven solutions.

The lubricant packaging industry is transforming thanks to the new trends in sustainability and anti-counterfeiting measures. Toward improving efficiency and ecological impact, companies are introducing refillable packages with AI-powered quality control and smart tracking. While companies are innovating even more sophisticated, lightweight containers that would improve product longevity, at the same time, they are working toward further reducing the carbon footprints of those containers.

An increasing number of manufacturers are venturing into new digital packaging solutions, including QR code-based authentication systems, so that they can also include digital means in combating counterfeiting. Companies may also use flexible packaging alternatives as part of their efforts to decrease plastic use while maximizing storage efficiency.

Year-on-Year Leaders

Technology suppliers should focus on automation, sustainable materials, and digital tracking systems to support the evolving lubricant packaging market. Partnering with automotive and industrial lubricant brands will accelerate adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Berry Global, Greif Inc., Mauser Packaging Solutions |

| Tier 2 | Mold-Tek Packaging, Scholle IPN, Balmer Lawrie |

| Tier 3 | Time Technoplast, CDF Corporation, Glenroy, SIG Combibloc |

Leading manufacturers are advancing lubricant packaging technology with AI-driven production, sustainable materials, and smart tracking solutions.

| Manufacturer | Latest Developments |

|---|---|

| Berry Global | Launched recyclable lubricant containers in March 2024. |

| Greif Inc. | Developed high-barrier tamper-proof packaging in April 2024. |

| Mauser Packaging | Expanded RFID-enabled smart closures in May 2024. |

| Mold-Tek Packaging | Released in-mold labeled premium lubricant packaging in June 2024. |

| Scholle IPN | Strengthened bag-in-box lubricant packaging in July 2024. |

| Balmer Lawrie | Introduced corrosion-resistant metal containers in August 2024. |

| Time Technoplast | Pioneered ultra-durable, lightweight packaging in September 2024. |

The lubricant packaging market is evolving as companies invest in sustainable materials, digital tracking, and advanced dispensing solutions.

The sector will continue integrating AI-driven quality control, digital authentication, and lightweight packaging materials. Manufacturers will continue to investigate sustainable formulations for HDPE for reduced plastic waste. Refillable packaging models would be adopted by companies to encourage circular economy initiatives.

Anti-counterfeiting smart closures with QR codes embedded in them are being developed by companies for authentication purposes. Digital tracking along the supply chain will fortify product safety while eliminating counterfeit sales. In addition, firms will work on automating lubricant packaging processes for greater efficiency and cost-effectiveness.

Leading players include Berry Global, Greif Inc., Mauser Packaging Solutions, Mold-Tek Packaging, Scholle IPN, Balmer Lawrie, and Time Technoplast.

The top 3 players collectively control 18% of the global market.

The market shows medium concentration, with top players holding 37%.

Key drivers include sustainability, smart tracking, lightweight materials, and anti-counterfeiting solutions.

Nitrogen Flushing Machine Market Report – Trends, Size & Forecast 2025-2035

Pan Liner Market Insights – Demand, Growth & Industry Trends 2025-2035

Perfume Filling Machine Market Report – Trends, Demand & Industry Forecast 2025-2035

Molded Pulp Packaging Machines Market Analysis - Growth & Forecast 2025 to 2035

Packaging Tensioner Market Analysis - Growth & Forecast 2025 to 2035

Packaging Films Market Analysis by Product Type, Material Type and End Use Through 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.