The liquid packaging board industry is expanding as a result of brands seeking sustainable, durable, and food-safe packaging solutions. There is a big demand across dairy, beverages, and pharmaceuticals, so manufacturers are focusing on recyclable, lightweight, and high-barrier packaging materials. However, there is a visible shift toward renewable resources and plastic-free coatings, so it is safe to say that this market is transforming in conjunction with sustainability regulations and the average consumer's preference toward eco-friendly packaging.

Companies are investing in fiber-based, multi-layer liquid packaging boards that enhance product safety and shelf life. Barrier innovations, biodegradability of coatings, and digital branding solutions are some approaches needed to address market requirements while still delivering high performance in packaging.

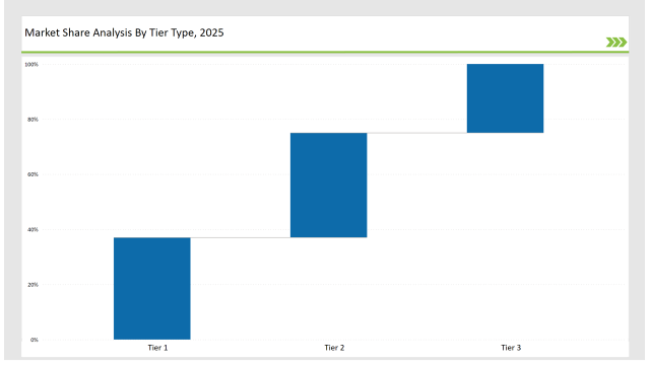

The market is held by some tier 1 players such as Tetra Pak, SIG Combibloc, and Stora Enso, which account for 37% of the overall market due to their advanced processing capability, strong distribution network, and sustainability leading edge in liquid packaging solutions.

Tier 2 includes those companies like BillerudKorsnäs, Greatview Aseptic, and Evergreen Packaging that grab 38% of the market by providing cost-efficient, high-performance liquid packaging board solutions for dairy, juice, and liquid food products.

Tier 3 comprises mainly regional and niche players providing a whole bunch of custom-made solutions for liquid boards, paper-based barriers, and some enhancements in digital printing, holding 25% of the market. The focus of these firms is local production, advanced coatings, and sustainability innovations.

Explore FMI!

Book a free demo

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Tetra Pak, SIG Combibloc, Stora Enso) | 17% |

| Rest of Top 5 (BillerudKorsnäs, Greatview Aseptic) | 12% |

| Next 5 of Top 10 (Evergreen Packaging, Elopak, Nippon Paper, Mondi Group, WestRock) | 8% |

The liquid packaging board industry serves multiple sectors where sustainability, food safety, and convenience are essential. Companies are developing innovative liquid board solutions to meet stringent industry requirements.

The entire process of manufacturing a liquid-packaging board is being optimized by the manufacturers with the coating of high-barrier coatings, fiber-based materials, and innovations in digital branding. These companies have helped improve moisture-resistant barriers to render boards more robust for extended shelf life. They are also integrating smart tracking technologies for real-time monitoring of the supply chain. Furthermore, lightweight and strong liquid packaging boards are being produced to enhance transportation cost savings and handling efficiency.

Sustainability and food safety innovations are transforming the liquid packaging board industry. Companies are integrating AI-driven manufacturing, water-based barrier coatings, and ultra-lightweight board materials to enhance performance and reduce environmental impact. Businesses are developing plant-based polymer coatings for fully biodegradable liquid packaging. Manufacturers are expanding their range of smart packaging solutions with QR codes for traceability and consumer engagement. Additionally, firms are launching advanced liquid barrier coatings that replace traditional plastic laminates.

Technology suppliers should focus on automation, sustainable coating solutions, and digital printing advancements to support the evolving liquid packaging board market. Partnering with beverage, dairy, and pharmaceutical brands will drive innovation and adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Tetra Pak, SIG Combibloc, Stora Enso |

| Tier 2 | BillerudKorsnäs, Greatview Aseptic, Evergreen Packaging |

| Tier 3 | Elopak, Nippon Paper, Mondi Group, WestRock |

Leading manufacturers apply AI-optimised production processes, high-barrier coatings, and sustainability-inspired innovations to enhance liquid packaging board technology. They incorporate intelligent packaging features such as embedded freshness indicators into packaging for improved product tracking. Producers are further improving lighter materials with impact resistance and durability while increasing investments in digital printing technology for high-quality and customizable branding on liquid packaging boards.

| Manufacturer | Latest Developments |

|---|---|

| Tetra Pak | Launched fiber-based, fully recyclable liquid board cartons in March 2024. |

| SIG Combibloc | Developed plant-based polymer-coated packaging in April 2024. |

| Stora Enso | Expanded plastic-free, high-barrier liquid packaging in May 2024. |

| BillerudKorsnäs | Released moisture-resistant, compostable liquid board in June 2024. |

| Greatview Aseptic | Strengthened aseptic carton technology in July 2024. |

| Evergreen Packaging | Introduced digital-printable liquid cartons in August 2024. |

| Elopak | Pioneered AI-driven production control in September 2024. |

The liquid packaging board market is under transformation as companies are investing in aspects like sustainability, smart coatings, and digital printing solutions. Biodegradable coatings have replaced the plastic-based laminates to enhance recyclability. Advanced moisture barriers are also installed to improve durability and preservation of liquid integrity. Integration of AI-controlled quality management systems is also seen among manufacturers for optimizing production technique efficiency and minimum material wastage.

The industry will continue integrating AI-driven production, smart packaging, and sustainable materials. Manufacturers will refine bio-based liquid barriers to replace plastic coatings. Businesses will adopt digital branding innovations for custom-printed liquid cartons. Companies will expand lightweight packaging to reduce shipping costs. Smart liquid cartons with QR codes will enhance supply chain traceability. High-barrier coatings will further improve shelf life and product freshness. Additionally, firms will enhance production efficiency with automated, energy-efficient machinery.

Leading players include Tetra Pak, SIG Combibloc, Stora Enso, BillerudKorsnäs, Greatview Aseptic, Evergreen Packaging, and Elopak.

Companies use FSC-certified paperboard, bio-based coatings, and recyclable fiber-based materials.

Manufacturers are replacing plastic coatings with plant-based barriers to improve recyclability.

Dairy, beverage, pharmaceutical, and liquid food industries use liquid packaging board extensively.

Nitrogen Flushing Machine Market Report – Trends, Size & Forecast 2025-2035

Pan Liner Market Insights – Demand, Growth & Industry Trends 2025-2035

Perfume Filling Machine Market Report – Trends, Demand & Industry Forecast 2025-2035

Molded Pulp Packaging Machines Market Analysis - Growth & Forecast 2025 to 2035

Packaging Tensioner Market Analysis - Growth & Forecast 2025 to 2035

Packaging Films Market Analysis by Product Type, Material Type and End Use Through 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.