The global leak testing machine market grows steadily, supported by the standards for greater safety in industries and environmental issues. With a projected growth of 4.7% CAGR, the market is going to reach USD 14,740.6 million by 2035 with strong demand for advanced leak detection solutions. The power plants, oil & gas refineries, and HVAC systems are giving more importance to leak testing. This is mainly for efficient working and maintaining compliance with regulatory requirements. The rate of adoption is likely to be high in those sectors where failure of safety might have severe consequences.

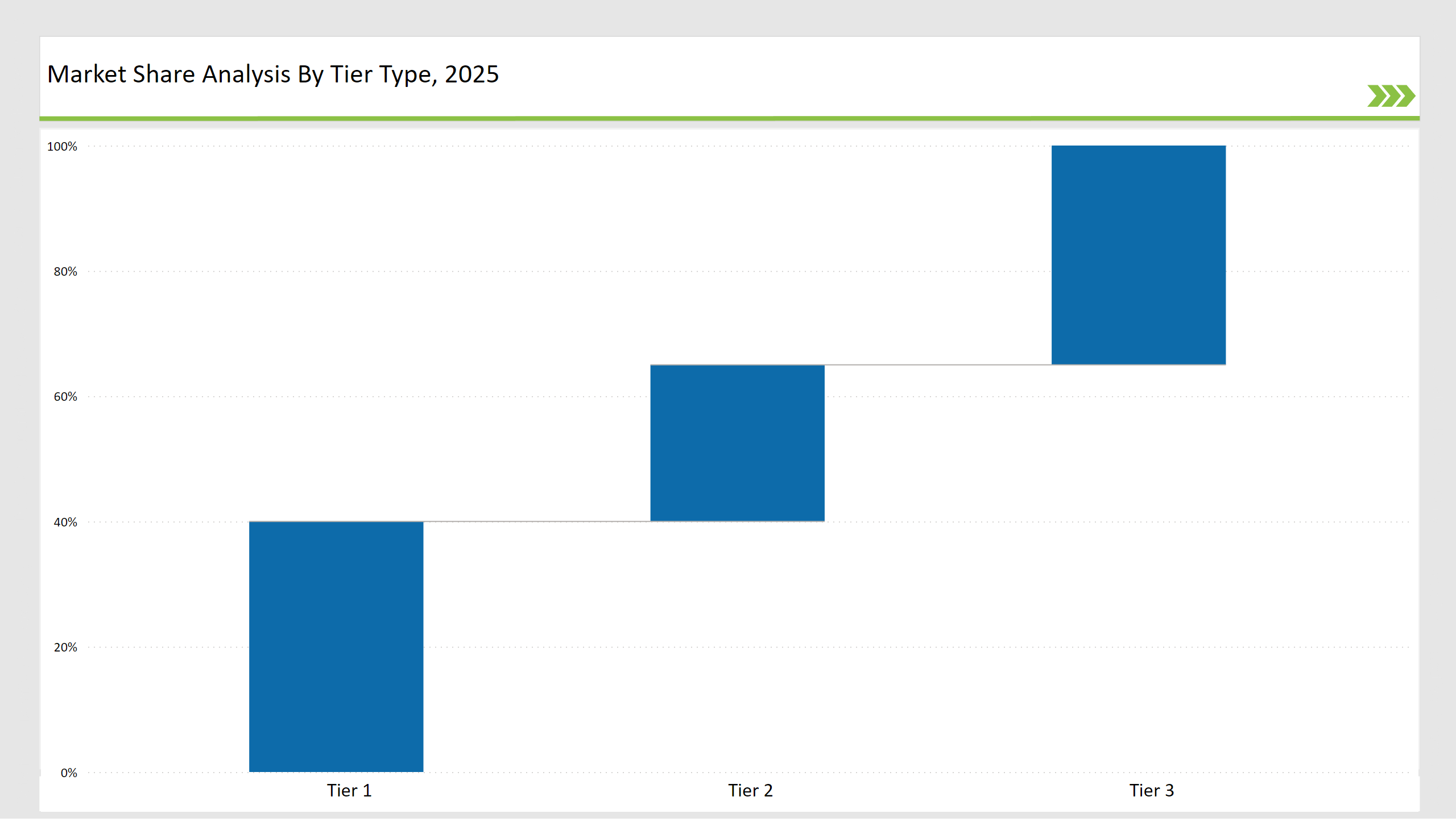

Market structure has a medium degree of consolidation in which Tier 1 companies like ATEQ Group, INFICON, and Pfeiffer Vacuum Technology own 40% of the market share around the world. Effective distribution networks, technological know-how, and high product portfolio make these firms able to continue competing in such an environment. Air pressure-based leak testing accounts for 50% of market share due to its adaptability and efficiency in various industrial applications. Included in the list of end-use sectors are chemical plants, which have the largest share of 25% due to the strict regulation requirements and the hazardous risk materials leak through.

Competitive strategies are seen to focus on automation and digital integration, where Tier 1 players introduce IoT-enabled and helium-based leak detection systems. Meanwhile, the Tier 2 players LACO Technologies and CETA Testsysteme gain 20% of the market share by being niche players catering to specific applications and low-cost solutions for small facilities. Regional manufacturers that also gain 40% of the market share through application-specific innovation targeting price-sensitive industries. Given the continuous progress in leak detection methodologies and efforts at standardization, the market is bound to experience further technological advancement and consolidation.

| Attribute | Details |

|---|---|

| Projected Value by 2035 | USD 14,740.6 million |

| CAGR during the period 2025 to 2035 | 4.7% |

Explore FMI!

Book a free demo

| Category | Industry Share (%) |

|---|---|

| Top 3 Players (ATEQ Group, INFICON, Pfeiffer Vacuum Technology) | 40% |

| Rest of top 5 (LACO Technologies, CETA Testsysteme) | 20% |

| Rest of Top 10 | 40% |

The market is fragmented, with top players influencing pricing strategies, technological advancements, and key partnerships with industrial sectors. Regional and niche players sustain themselves by offering affordable and application-specific products to localized markets.

Air pressure-based leak testing represents the market leader by holding 50% of the market because of its high precision, versatility and cost-effectiveness. It applies widely in various sections of the HVAC, chemical and oil & gas industries where a tight seal on their systems is imperative.

Even companies like ATEQ Group and Pfeiffer Vacuum Technology are at the helm to give air pressure-based solutions a much-needed edge using IoT and automation for real-time monitoring and improved detection of micro leaks. As a non-destructive test technique adaptable to mass production lines, air pressure testing is bound to remain at the top, especially considering the growing need for efficiency and regulatory compliance within industries.

Gas-based leak detection by using helium or hydrogen as tracer gases is important for high-sensitivity applications, such as power plants and water treatment facilities. In this regard, INFICON leads this market with innovative gas-based solutions that provide unparalleled accuracy in detecting minute leaks. Pipeline storage tanks remain a hydrostatic testing favorite, particularly for oil & gas and water treatment.

LACO Technologies is a modular hydrostatic solution company catering to large-scale applications that are very much safety- and durability-conscious in those industries. All three methodologies will be further innovated with emphasis on automation and data-driven diagnostics in light of increasing global leak prevention and sustainability requirements

Chemical plants are accounted for 25% of leak testing machine, driven by high safety and environmental regulations that make it necessary to detect leaks exactly to avoid hazards spills and emission. ATEQ Group tops this segment due to advanced air pressure and tracer gas-based systems tailored for the critical infrastructure: reactors and pipelines under high-pressure. The HVAC and refrigeration sector is another large user, where air pressure and gas-based testing are used to improve system efficiency and achieve new standards of environmental standards.

Pfeiffer Vacuum Technology plays a leading role in these efforts by making specialized solutions for HVAC manufacturers to ensure they meet ultra-stringent leakage limits. The oil & gas refineries pay particular emphasis on leak detection as safety risks and operational cessation in such highly volatile refinery processes are at significant risk.

INFICON has made a strong presence in this market by developing helium-based detection technologies that allow for the early detection of leaks in high-risk equipment such as heat exchangers, storage tanks, and transmission pipelines.

ATEQ Group:

ATEQ Group has solidified its leadership position in the market for leak testing by enhancing air pressure testing systems, mainly catering to the chemical and HVAC sectors. Considering that chemical processing units require the precise detection of leakage, ATEQ has established solutions that are capable of identifying even minute leakage in reactors, pipelines, and storage units. The company's HVAC-specific solutions ensure compliance with changing energy efficiency regulations, thereby helping the manufacturer minimize refrigerant loss and the lifespan of systems.

IoT-enabled leakage-testing products have also been implemented by ATEQ to help manufacturers test remotely. The advancement allows for real-time diagnostic and predictive maintenance and ultimately reduces downtime and issues related to quality control. The cloud-based analytics integration enhances the value proposition of ATEQ, wherein data-driven insights are used for the optimization of industrial clients' leak detection process. With the new developments in the company, ATEQ is further increasing its stronghold on the high-precision leak testing in critical industries where end usage takes place.

INFICON:

INFICON has further consolidated its position in the helium-based leak detection segment by concentrating on high-precision applications in power plants and oil & gas refineries. The company's solutions are targeting the rising demand for leak detection in high-risk settings, where even the smallest leak might pose major safety hazards and inefficiencies in operation.

It offers more efficient testing technology based on helium in comparison to the traditional leakage detection that is used by INFICON with respect to following industry standards regarding the heat exchanger, storage gas tank, and refining equipment.

The company has expanded its regional reach after recognizing growth prospects in Asia-Pacific by forming strategic partnerships with local distributors and industrial players. With this step, INFICON is in a better position to address the growing need for innovative leak detection in developing markets, especially where industrial activities are increasing, and environmental rules are getting stringent. By continuously innovating helium-based detection methodologies, INFICON is well-positioned to cater to ultra-sensitive leak detection solutions that many industries are requiring.

Pfeiffer Vacuum Technology:

Pfeiffer Vacuum Technology has strengthened its leadership in the HVAC and refrigeration industry with its new generation micro-leak detection systems. They have improved the sensitivity and the testing speed. This is where the industry, increasingly demanding more accurate, faster, and eco-friendly leak testing, comes into play. Tightening regulations regarding refrigerant emissions have made it necessary for HVAC manufacturers to reduce leakage in cooling and refrigeration systems, for which Pfeiffer's gas-based solutions can be used.

The company has heavily invested in R&D into making its mass spectrometry and tracer gas detection technologies much more accurate and reliable for the critical applications for which they are being used. With advanced vacuum technology, Pfeiffer improved the detection of even the smallest leaks, thereby ensuring that its system efficiency could be optimized with lower maintenance costs.

The company’s focus on innovation extends to automation, with intelligent leak detection systems designed to support large-scale manufacturing processes. As the HVAC regulations keep changing, Pfeiffer's focus on R&D ensures it is a preferred partner for manufacturers seeking precision leak testing solutions.

LACO Technologies:

LACO Technologies now adds modular hydrostatic testing solutions made for large-sized water treatment plants and thermal ones to its wide market. With this, critical infrastructure applications remain highly relevant and are made with industries requiring utmost structural integrity preservation under high pressure. LACO Technologies brings modular systems within industrial facilities.

These are done to allow customization of leak detection configurations as regards the facility's specific operation demands. LACO has further consolidated its position in North America by establishing strategic relationships with utility companies and industrial manufacturers to build further strength in the leak testing capabilities.

The company meets the increasingly growing demand for cost-effective, reliable, leak detection at water treatment facilities, energy plants, and thermal power generation units through its scalable, highly efficient testing solutions.The rising investments in water infrastructure and energy efficiency measures have already driven LACO's hydrostatic solutions to support the industries wanting to enhance operational safety and regulatory compliance.

CETA Testsysteme:

CETA Testsysteme has cemented its position in providing affordable leak testing solutions via air pressure and hydrostatic solutions to mainly water treatment plants as well as the smaller chemical processing facilities. With industries demanding leak detection methods that are rather affordable yet effective, CETA has concentrated on perfecting the precision and effectiveness of its leak detection systems provided via compressed air pressure.

The CETA Testsysteme solutions offer balanced performance with cost-effectiveness, making them suitable for mid-sized applications in industry. The company also expanded its network of distribution throughout Europe to continue to further increase its market strength in the significant markets where regulations for leak detection are stricter.

By strengthening regional partnerships and the supply chain capability, CETA can offer prompt delivery and locally available technical assistance, ensuring smoother adoption of the solutions. Based on affordability, practical implementation, and a sense of value addition, CETA continues to fulfill the needs of industrial players that are seeking tough and cost-effective leak testing technologies.

| Tier | Examples |

|---|---|

| Tier 1 | ATEQ Group, INFICON, Pfeiffer Vacuum Technology |

| Tier 2 | LACO Technologies, CETA Testsysteme |

| Tier 3 | Regional and niche players |

| Company | Initiative |

|---|---|

| ATEQ Group | Expanded air pressure testing systems for chemical and HVAC sectors; introduced IoT-enabled solutions for remote leak monitoring. |

| INFICON | Focused on helium-based leak detection for power plants and oil & gas refineries; strengthened presence in Asia-Pacific through regional partnerships. |

| Pfeiffer Vacuum Technology | Launched advanced micro-leak detection systems for HVAC and refrigeration; invested in R&D to enhance sensitivity and speed of gas-based solutions. |

| LACO Technologies | Introduced modular hydrostatic testing solutions for water treatment and thermal plants; expanded footprint in North America through strategic collaborations. |

| CETA Testsysteme | Developed cost-effective air pressure and hydrostatic solutions for water treatment plants and small chemical facilities; enhanced European distribution network. |

The leak testing machine market is to witness continuous growth as industries increasingly focus on safety, quality compliance, and efficiency in operations. Key leaders need to invest in air pressure and gas-based leak detection techniques that continue to dominate the globe primarily for their precision and capability across critical applications. Emerging opportunities in water treatment and power generation are driven by infrastructure upgrades and stringent environmental policies.

Chemical plants and HVAC systems drive the overall market demand, but with a strong presence of IoT-enabled and automated leak testing solutions that make a difference for real-time monitoring and predictive maintenance, this solution will have more room for competition in performance.

Manufacturers should then invest in improving sensitivity, speed, and automation capabilities in order to be able to remain ahead in competition. Besides, strategic alliances with regional distributors will be vital for market penetration in cost-sensitive regions. As industrial safety standards continue to change, companies that take proactive steps in integrating digitalization, precision testing, and scalable solutions will be best placed for long-term market leadership.

Leading companies in the global leak testing machine market include ATEQ Group, INFICON, and Pfeiffer Vacuum Technology, which collectively hold a significant share due to their strong technological expertise, extensive product portfolios, and established global distribution networks.

Key hardware types include detectors and sensors, which play a crucial role in identifying and measuring leaks in various systems. These devices are central to leak testing machines as they provide the necessary accuracy and sensitivity for detecting even the smallest leaks.

The chemical plants, water treatment, and oil & gas refineries are the primary drivers of demand for leak testing machines globally. These industries require precise leak detection to comply with stringent safety regulations, prevent hazardous spills, and maintain operational efficiency, with growing adoption of advanced and automated solutions.

The market is expected to experience steady growth, driven by increasing industrial safety regulations, environmental concerns, and the rising adoption of advanced, automated testing solutions.

Technological advancements are significantly enhancing the precision, efficiency, and automation of leak testing machines. Innovations like IoT-enabled solutions allow real-time monitoring and predictive maintenance, improving operational efficiency.

ADAS Calibration Equipment Market Analysis by Vehicle Type, End User, and Region from 2025 to 2035

Capillary Electrophoresis Market Analysis by Application, End-user, and Region Through 2025 to 2035

Cable Fault Locator Market Analysis by Portability, Product, End User, and Region to 2025 to 2035

Digital LUX Meter Market Growth - Trends & Forecast 2025 to 2035

Industrial Insulation Tester Market Growth - Trends & Forecast 2025 to 2035

Pavement Tester Market Growth - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.