The business for interlocking boxes is escalating due to a growing priority of organizations for safe, sturdy, and environment-friendly packaging. Increasing demands from various sectors such as e-commerce, retail, food, and industry are leading manufacturers into innovation with new dimensions of sustainable materials and tamper-proof designs, with highly advanced die-cutting technologies. Today, a lot of efforts have been put toward designing lightweight but sufficiently strong interlocking mechanisms, introducing smart packaging features, and benefiting from custom designs for better protection and branding.

Manufacturers optimize production using AI for defect detection, automatic folding systems, and recycled materials for greater cost efficiency and lower impact on the environment. The trend in the industry is shifting to biodegradable board options and PCR-based (post-consumer recycled) as well as reusable interlocking boxes that would suit consumer preferences and regulatory policies.

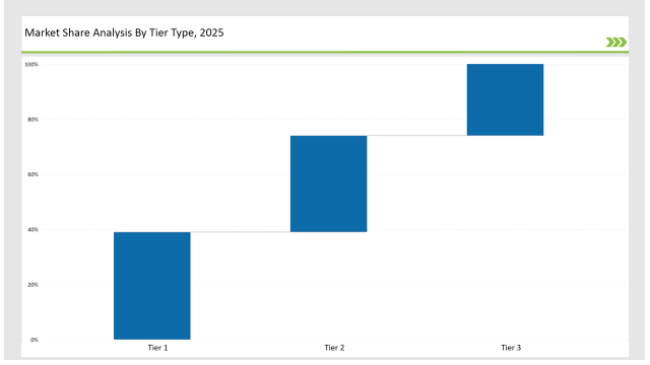

Among all Tier 1 players, WestRock, Smurfit Kappa, and DS Smith hold 39% of the market due to their leadership in the field in high-performance corrugated packaging, sustainability solutions, and vast distribution networks.

Tier 2 companies include International Paper, Mondi Group, and Pratt Industries, representing 35% of the market for their portfolio of affordable, highly customizable, and specialty interlocking boxes designed for different purposes.

Regional and niche players with a focus on premium, eco-friendly, and high-strength interlocking boxes comprise Tier 3, holding 26% of the market. These companies tend to focus their efforts on producing localized manufacturing, specialized coatings, and ergonomic packaging designs.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (WestRock, Smurfit Kappa, DS Smith) | 20% |

| Rest of Top 5 (International Paper, Mondi Group) | 13% |

| Next 5 of Top 10 (Pratt Industries, Rengo Co., Stora Enso, Oji Holdings, Georgia-Pacific) | 6% |

Market Concentration (2025E)

The interlocking boxes industry serves multiple sectors where durability, security, and sustainability are crucial. Companies are developing innovative packaging solutions to ensure product safety and enhance branding. They are incorporating reinforced edges and double-locking mechanisms to improve box strength and stability. Additionally, manufacturers are adopting water-resistant coatings to protect packaging from moisture damage and extend shelf life.

Manufacturers are optimizing interlocking boxes with sustainable materials, enhanced security features, and smart tracking integrations. They are enhancing box durability by integrating reinforced corner designs for added strength. Additionally, companies are adopting water-resistant coatings to protect products from moisture damage. Businesses are also implementing AI-driven quality control systems to detect defects and maintain consistency in packaging production.

Automation and sustainability are revolutionizing the interlocking boxes industry. Companies are employing AI-powered manufacturing, ultra-light corrugated boards, and high-strength locking devices to make packaging more efficient. Companies are designing ultra-thin but very durable materials in a bid to reduce material consumption. Companies are bringing in packaging with embedded QR codes for tracking and interactive branding. Companies are employing water-based adhesives and coatings in a bid to increase recyclability. They are also enhancing impact resistance to offer better product protection during shipping. Furthermore, businesses are integrating modular designs that facilitate quick assembly and efficient stacking.

In the Interlocking Boxes Industry Technology suppliers should prioritize automation, eco-friendly materials, and smart packaging innovations to support the growing interlocking boxes market. Collaborating with e-commerce, logistics, and retail brands will drive adoption and market growth.

1. Sustainability Trends: Develop biodegradable and recyclable interlocking box solutions to meet eco-friendly packaging demands.

2. Automation & Efficiency : Enhance manufacturing with high-speed die-cutting, folding, and assembly technologies.

3. Customization & Scalability: Offer personalized branding, tamper-evident features, and modular design options for various industries.

4. Regional Growth Dynamics: North America and Europe emphasize sustainability, while Asia-Pacific focuses on cost-effective, high-volume production.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | WestRock, Smurfit Kappa, DS Smith |

| Tier 2 | International Paper, Mondi Group |

| Tier 3 | Pratt Industries, Rengo Co., Stora Enso, Oji Holdings, Georgia-Pacific |

Leading manufacturers are advancing interlocking box technology with AI-powered production, eco-friendly materials, and ergonomic designs. They are incorporating high-speed automation to enhance precision and reduce production time. Additionally, companies are developing reinforced locking mechanisms to improve structural integrity and withstand heavy loads. Businesses are also integrating digital printing for customizable branding and traceability solutions.

| Manufacturer | Latest Developments |

|---|---|

| WestRock | Launched recyclable, tamper-proof interlocking boxes in March 2024. |

| Smurfit Kappa | Developed moisture-resistant, high-strength packaging in April 2024. |

| DS Smith | Expanded lightweight, compostable box solutions in May 2024. |

| International Paper | Released greaseproof, food-safe interlocking boxes in June 2024. |

| Mondi Group | Strengthened anti-static, protective packaging for electronics in July 2024. |

| Pratt Industries | Introduced smart-tracking, QR-enabled packaging in August 2024. |

| Rengo Co. | Pioneered ultra-thin, high-load-bearing interlocking materials in September 2024. |

The boxes interlocking business is evolving as companies invest in green materials, AI-driven defect detection, and tamper-evident packaging technology. They are designing high-strength, low-weight corrugated materials to enhance strength at reduced costs. Smart tracking features are also incorporated by businessmen to provide supply chain visibility and security. Manufacturers also apply automated folding and sealing machines to maximize production and reduce wastage.

Manufacturers will continue to advance AI-based defect detection, modular pack designs, and smart tracking technologies. Companies will continue to use high-strength, light-weight materials for cost savings and recyclability. Companies will add digital printing to personalized, branded packages. Smart packaging with such features as embedded NFC tags and anti-theft will gain popularity. In addition, AI-based analytics will enhance supply chain efficiency and reduce packaging waste. Businesses will develop impact-resistant designs to ensure products are safer during transit. Businesses will also develop moisture-repellent coatings to enhance the longevity of interlocking boxes in different storage conditions.

Leading players include WestRock, Smurfit Kappa, DS Smith, International Paper, Mondi Group, Pratt Industries, and Rengo Co.

The top 3 players collectively control 20% of the global market.

The market shows medium concentration, with top players holding 39%.

Key drivers include sustainability, automation, high-strength materials, and smart tracking solutions.

Explore Packaging Consumables and Supplies Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.