The worldwide industrial marking equipment market will increase gradually from 2025 to 2035 due to the growing need for robust, precise, and traceable marks in production and manufacturing processes. From dot peen marker mark machines for industrial applications to laser engravers are required to produce behind identification codes, serial numbers, and logos on products and parts, meeting industry needs, enhancing quality inspection, and establishing traceability in supply chains. Applications find their way in such wide industries as the manufacture of automobiles, aerospace, manufacture of electronics, and manufacture of healthcare equipment.

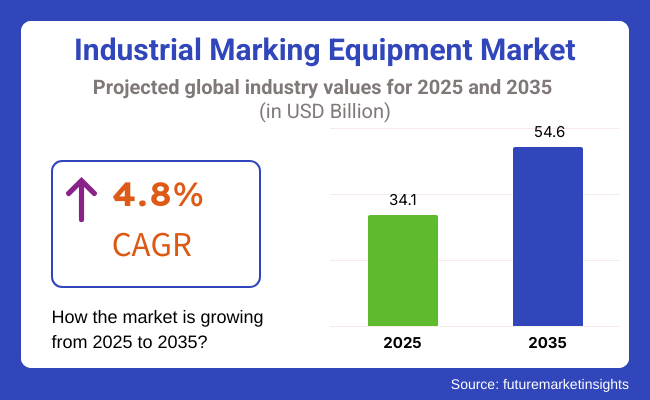

The industrial marking machinery industry was approximately USD 34.1 Billion in 2025. The market will be USD 54.6 Billion in 2035 growing at a compound annual growth rate (CAGR) of 4.9%. Increased demand for accuracy marking solutions, increase in regulatory requirements for product traceability, and increased application of automated manufacturing lines are some of the key factors driving the market. Advancements in laser marking technology and development of eco-friendly marking solutions are also driving market growth.

Explore FMI!

Book a free demo

North America is a prominent industrial marking machinery market due to the mature manufacturing base within the region and stringent product identification regulations. High concentration of auto, aerospace, and medical device manufacturers in the United States and Canada all necessitate precise marking solutions. Pressure towards greater automation as well as adoption of Industry 4.0 technologies has created demand for laser marking machines as well as sophisticated marking tools.

Europe remains a significant market for the industrial marking equipment industry through assistance by stringent quality requirements as well as environmental issues. Italian, French, and German production is highly robust with excellent demand rates for marking equipment for the automotive and electronics sectors.

Adoption of high-tech marking technology like fiber lasers and green-inks due to stringent product traceability in some EU directives is propelling the applications. Market growth is backed by additional investment in automated production lines and increasing requirements for direct part marking solutions.

The Asia-Pacific market will be expected to post the highest growth among industrial marking equipment markets. Due to the industrialization being spurred, more manufacturing companies, and increased focus on product traceability, countries like China, India, and Japan are generating demand for sophisticated marking technologies.

East Asia's successful electronics industry, which is accelerating automotive and airplane production, has fostered an enormity of demands for hard and accurate marking systems. The demand for the optimization of production quality and sustainability for the world's market within the region is adding more demands to laser and dot peen marking systems, and thus the Asia-Pacific region is a new-emerging market.

Challenge

High Equipment Costs and Compliance with Industrial Standards

High precision marking equipment serves automotive, aerospace, electronics, and packaging with product traceability, compliance, and anti-counterfeit. On the other hand, retrofitting existing production lines with industrial marking systems involves a considerable investment in automation systems, software integration, and an upgrade to the latest laser or inkjet technologies.

Global regulations are also evolving including ISO standards and serialization mandates requiring regular updates to marking systems. The solution lies in investing in modular, AI-integrated marking paradigms, predictive maintenance systems and sustainable marking alternatives to help the manufacturers save on cost and simultaneously improve compliance.

Opportunity

Growth in Smart Manufacturing and Sustainable Marking Solutions

The growth of Industry 4.0, automation, and environmentally friendly marking solutions is expected to create lucrative opportunities in the Industrial Marking Equipment Market. Laser marking, RFID-based tagging, and high-grip inkjet systems are in higher demand as industries transition to digital manufacturing. This includes using AI-powered inspection systems, cloud-based traceability platforms, and IoT-enabled marking devices that enhance accuracy and efficiency.

The growing trend for sustainable marking solutions such as water-based inks, recyclable laser etching, and solvent-free printing further propels the market. Innovative smart tracking solutions, cloud-based digital marking software, and energy-efficient marking systems will give companies a competitive edge in the evolving industrial landscape.

Between 2020 and 2024, increasing demand for traceability, prevention of counterfeiting, and adherence to serialization laws. So, to focus on factors: An industry for progressed marking precision, to coordinate versatile laser marking systems, and to embrace eco-friendly marking alternatives.

But this market has seen limited expansion due to challenges such as the high implementation costs system, the need for frequent equipment maintenance, and issues related to technical integration. As a counter measure to these problems, industry participants turned to AI-powered laser etching, cloud-based marking management systems and advanced vision inspection solutions to enhance operational efficiency.

Looking ahead to 2025 to 2035, envision a future in which new heights are powered by AI-driven marking automation, hybrid digital-print marking, and secured traceability through distributed ledger technology (e.g. block chain). The increasing use of autonomous production lines, robotic-assisted marking systems, and quantum dot coding for high-security applications will transform the industrial marking landscape.

Moreover, the growing emphasis on environmentally friendly marking technologies, green UV-curable inks, and energy-efficient fiber lasers in the marking process are expected to steer the overall market towards greener and more economical marking solutions. The industrial marking equipment market will be defined by companies combining AI-based predictive maintenance tools, automated quality testing, and sustainable ink options.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Compliance with ISO, FDA, and anti-counterfeit regulations |

| Technological Advancements | Growth in laser marking, inkjet printing, and RFID tagging |

| Industry Adoption | Increased use in automotive, aerospace, and electronics |

| Supply Chain and Sourcing | Dependence on conventional ink and laser marking materials |

| Market Competition | Dominance of traditional marking equipment manufacturers |

| Market Growth Drivers | Rising demand for traceability, serialization, and anti-counterfeiting |

| Sustainability and Energy Efficiency | Initial adoption of water-based inks and laser marking |

| Integration of Smart Monitoring | Limited real-time tracking of marked products and process efficiency |

| Advancements in Marking Technology | Use of traditional laser etching, dot peen, and inkjet marking |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Expansion of blockchain-based traceability, AI-driven compliance monitoring, and zero-emission marking policies. |

| Technological Advancements | Widespread adoption of AI-powered inspection, hybrid digital-print marking, and real-time cloud-based tracking. |

| Industry Adoption | Expansion into medical devices, AI-driven smart packaging, and next-gen product authentication. |

| Supply Chain and Sourcing | Shift toward biodegradable inks, nanomaterial-based etching, and sustainable marking solutions. |

| Market Competition | Growth of AI-integrated marking providers, digital serialization solutions, and eco-friendly printing technology startups. |

| Market Growth Drivers | Increased investment in AI-driven authentication, quantum dot security coding, and carbon-neutral marking systems. |

| Sustainability and Energy Efficiency | Full-scale deployment of recyclable ink technologies, energy-efficient laser systems, and emission-free marking alternatives. |

| Integration of Smart Monitoring | AI-enhanced defect detection, IoT-connected marking solutions, and predictive failure analytics. |

| Advancements in Marking Technology | Evolution of automated robotic marking, UV-curable nano-printing, and self-learning marking machines. |

Growing demand for industrial marking equipment in United States due to stringent regulatory labeling requirements, automation of manufacturing, and growing demand for product traceability. High-precision laser marking, inkjet printing, and dot peening for permanent part identification and compliance with safety standards are in demand in industries such as automotive, aerospace, electronics, and medical devices.

The demand for modern automated marking systems will only continue to grow as smart manufacturing and IoT-enabled production lines become more prevalent. Moreover, growth in industrial marking solutions is also driven by government regulations, such as FDA labelling standards for medical devices and UDI (Unique Device Identification) mandates.

| Country | CAGR (2025 to 2035) |

|---|---|

| USA | 5.2% |

The market in the United Kingdom is steadily growing due to increasing regulatory scrutiny towards marking for counterfeit prevention and advances in packaging technology. High-resolution inkjet, laser, and thermal transfer marking solutions are being adopted by food & beverage, pharmaceuticals, and automotive industries to fulfil stringent labeling and coding specifications.

Changes to product regulations as a result of Brexit, combined with the UK’s expanding export sector, mean that companies are investing in advanced marking systems to comply with requirements globally throughout the supply chain.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK | 4.6% |

The strict regulatory framework and robust manufacturing output drives the growth of the European Union (EU) industrial marking equipment market. Germany, France, and Italy are at the forefront of adopting high-performance marking and coding systems across industries such as industrial automation, pharmaceuticals, and precision engineering.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union (EU) | 4.9% |

Japan is one of the largest consumers of industrial marking equipment, known for high-tech manufacturing, precision engineering, and broader adoption of automatic robotics. The automotive, semiconductor and medical device industries in the country depend on ultra-precise laser and dot peening marking systems for product authentication, traceability and quality assurance.

Japan is placing more emphasis on miniaturization, particularly regarding electronics and IoT devices that influences the adoption of micro-marking technologies in the country, while a highly regulated medical sector in Japan requires unique device identification (UDI) coding for traceability.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 5.0% |

The South Korean industrial marking equipment market is booming, thanks to the country’s flourishing electronics and semiconductor sectors, adoption of smart factory systems, and the emergence of electric vehicle (EV) manufacturing..

South Korea is also at the forefront of 5G and AI-powered manufacturing, and where high-speed, automated marking systems are increasingly important to supply chain traceability. The rising pharmaceutical industry and expanding government initiatives for anti-counterfeiting are also providing impulses to demand for secure marking solutions.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 5.1% |

Laser marker systems and inkjet printers dominate the industrial marking equipment market, with a number of industries such as aerospace, electronics, and automotive spending on high-precision marking technologies to facilitate compliance, enhance product traceability, and create product branding. Due to this, such high-level marking solutions are in the focus when permanent, high-grade markings on the industrial parts have to be achieved while keeping tampering at the lowest level possible, thereby making the market compatible with regulations and traceable in terms of the inventory, deterring counterfeits.

As a result, laser marker systems are one of the most favoured industrial marking solutions; they achieve high-speed, permanent markings with a highly accurate level of precision and low material damage. With distinct advantages of non-contact and wear-resistance, as well as environmental protection, laser marking technology has been widely used in this area, gaining permanent readability and traceability compared with the traditional marking method.

Increasing need for low-cost, permanent and high-resolution industrial marking like barcodes, serial numbers, QR codes and branding elements are one of the key factors that are fuelling the adoption of this technology, as industries focus on traceability, anti-counterfeiting, and compliance with international product identification standards. Researchers predict that more than 65% of industrial sectors use laser marking technology, ensuring end-use sectors with precision and durability for better demand for this segment.

The growing automation-driven manufacturing such as robotic-based assembly lines, Integration of Industry 4.0, Smart tracking system, and others have bolstered the market demand assuring high adoption of laser marker systems to enable uninterrupted production workflows.

Further adoption by the integration of AI-powered marking solutions with real-time defect detection, automated positioning adjustment, and laser intensity optimization have encouraged adoption, ensuring better efficiency, no human taking control.

The growth of fiber laser marking technology, whose high energy efficiency facilitates precision deep engraving, and which can be applied to a spectrum of industrial materials, has further optimized market growth ensuring greater versatility for application in aerospace, medical, and electronics.

The emergence of hybrid laser marking systems with integrated CO₂, fiber and UV laser marking, was another factor that led to greater flexibility in the marking of a high variety of material compositions and market needs, spurring growth.

Laser marker systems provide permanent marking, high precision, and is maintenance-free; however, the initial investment cost can be higher, and safety hazards can arise from high-power lasers, with restrictions on marking heat-sensitive and highly reflective materials. In contrast, since AI-based laser automation, intelligent marking software, next-gen laser scanning, and other advanced developments are heightening productivity, affordability, and functional safety, they are supporting the growth of the laser marker systems market.

Ink jet printers have quickly captured much of the market, especially in high-speed production settings such as large scale packaging and batch coding, where industries are placing greater emphasis on flexible and cost effective marking technologies. Continuous ink jet printing is a fast, flexible, contactless marking solution ideal for dynamic production lines and high-volume industrial processes, as opposed to laser markers.

Owing to the industrial requirement to integrate solutions for high-speed coding & batch marking, with real-time variable data printing, expiry date coding, and lot number marking, the demand for inkjet printers is on the rise as industries are finding it lucid to adapt for more reliable and cost-effective marking processes. According to studies, more than 55% of industrial packaging and labelling applications utilize inkjet technology, maintaining strong demand for this industry.

The booming e-commerce and supply chain tracking that includes features such as smart packaging, automated inventory labelling, and just-in-time production workflows have consolidated market demand leading to widespread adoption of inkjet printers in logistics and warehousing applications.

Smart ink technologies that include quick-dry, UV-protected, and solvent-based inks for maximum operational efficiency in extreme environmental conditions have also contributed to growth, allowing superior performance even in harsh industrial environments.

The emergence of AI-enabled print management systems with real-time ink consumption tracking, automatic maintenance scheduling, and predictive analytics for print head operation has streamlined market development, leading to enhanced operational efficacy and cost savings.

The integration of hybrid inkjet marking solutions that include thermal and continuous inkjet (CIJ) printing systems has further bolstered market growth by providing enhanced compatibility for various printing needs.

However, disadvantages such as ongoing maintenance requirements, risk of ink smudging in high humidity, and the comparatively temporary nature of the inkjet process when compared with permanence of laser marking inhibit the inkjet printer segment despite advantages of speed, cost, high compatibility with various substrates, and suitability for flexible structures. But with new developments in AI-powered inky media optimization, environmentally friendly green ink formulations, and intelligent IoT-enabled ink-jetting technologies all helping reduce waste, create customized operations and enable overall longevity, inkjet is set for continued growth in the industrial marking sector.

The automotive and electronics & semiconductors segments are among the two prominent market drivers as industries are progressively incorporate advanced industrial marking solutions in an effort to boost product traceability, anti-counterfeiting efforts, and regulatory compliance.

The automotive segment is one of the largest markets for industrial marking solutions, which includes high-precision component labelling, engraving of VIN (vehicle identification number), and permanent branding of parts for traceability. The automotive sector does not have the luxury to implement simple frosting solutions, as it demands long-lasting and fast marking technology for safety compliance and operations in global supply chain.

Increasing demand for serialized tracking of automotive parts with features such as real time production tracking, counterfeit prevention, and supply chain security has driven adoption of industrial marking systems, as OEMs and auto parts manufacturers focus on regulatory compliance and recall management. According to studies, more than 70 percent of the global automotive manufacturers use laser and inkjet marking to identify the components and will continue to have significant demand for this segment.

The growing production of electric vehicles (EVs) with battery serialization, electronic circuit marking, and lightweight material branding has bolstered market demand, leading to increased adoption of high-precision marking solutions in next-generation automotive manufacturing.

The automotive marking segment accounts for the aforementioned aspects as well as the challenges related with the differences in levels of regulatory standardization prevalent between many global markets, the durability of marking on lightweight materials and the cost aspects related to mass production. Emerging innovations in AI-supported VIN tracking, laser-enhanced component serialization, and RFID-integrated marking solutions are not only improving operational efficiency, legislative compliance, and supply chain transparency amongst the manufacturers, but are also ensuring continued expansion of the industrial marking solutions in the automotive applications.

Strong market adoption across the electronics and semiconductor sector has been noted, particularly in the area of microchip manufacturing, PCB (Printed Circuit Board) identification and high resolution, and high-speed component coding, as manufacturers continue to invest in industrial marking technology to ensure traceability and authenticity. In contrast to typical product labelling, semiconductor marking must use ultra-precise, non-product-damaging solutions to avoid negatively affecting the performance of electronic components.

As electronics manufacturers increasingly opt for sophisticated authentication solutions due to emerging counterfeit protection needs in electronic components, for instance, with permanent micro-markings, anti-tampering labels, and laser-engraved serial numbers, growing adoption of industrial marking systems has been witnessed in the global industrial marking systems market.

While its precision, product authentication, and compliance with regulatory norms offer several benefits, the segment for electronics marking is confronted with challenges like minimal marker surface area on the miniaturized components, sensitivity of material handling restrictions, and environmental durability standards. Nevertheless, advancements in AI-based ultra-fine laser marking, nanoscale engraving and RFID-enabled electronic part authentication are enhancing efficacy, product security and durability, paving the way for growth of industrial marking solutions market within electronics and semiconductor manufacturing.

The global industrial marking equipment market is witnessing significant growth driven by the increasing demand for product traceability and compliance with regulations, as well as the growing automation in manufacturing and packaging industries. Vendors are emphasizing laser marking, inkjet printing, and AI-based marking systems to improve efficiency, accuracy, and durability. In addition to Global marking equipment, Industrial coding and labeling solution providers, Automation technology companies also boost technological advancement in permanent marking, high-speed coding, and RFID-integrated tracking solutions.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Videojet Technologies Inc. | 15-20% |

| Markem-Imaje (A Dover Company) | 12-16% |

| Domino Printing Sciences (Brother Industries Ltd.) | 10-14% |

| Trotec Laser GmbH | 8-12% |

| Hitachi Industrial Equipment & Solutions Ltd. | 5-9% |

| Other Companies (combined) | 40-50% |

| Company Name | Key Offerings/Activities |

|---|---|

| Videojet Technologies Inc. | Develops inkjet, laser, and thermal transfer marking solutions for packaging, industrial, and pharmaceutical applications. |

| Markem-Imaje | Specializes in high-resolution coding and marking systems, integrating traceability and anti-counterfeiting technology. |

| Domino Printing Sciences | Manufactures inkjet, laser, and print-and-apply labeling systems with AI-powered monitoring for industrial applications. |

| Trotec Laser GmbH | Provides high-precision laser marking systems for durable product identification and metal engraving applications. |

| Hitachi Industrial Equipment & Solutions Ltd. | Offers industrial inkjet printers and marking solutions optimized for high-speed production environments. |

Key Company Insights

Videojet Technologies Inc. (15-20%)

With AI-assisted quality assurance, Videojet they are a leader in the smart inkjet, laser, and coding industrial marking equipment market.

Markem-Imaje (12-16%)

Markem-Imaje specializes in high-speed, permanent marking solutions, enabling traceability and compliance in manufacturing and logistics.

Domino Printing Sciences (10-14%)

Domino specializes in advanced digital marking technologies and high-resolution printing with RFID-ready labeling systems.

Trotec Laser GmbH (8-12%)

Trotec is into developing laser engraving and marking solutions including integrating precision marking for a variety of automotive, electronics, and other industrial components.

Hitachi Industrial Equipment & Solutions Ltd. (5-9%)

Hitachi produces high-volume, industrial-grade inkjet printers and marking systems used for fast and low-cost product identification.

Other Key Players (40-50% Combined)

Various industrial marking and coding equipment manufacturers drive next-generation marking innovations, AI-based quality control, and high-speed automatic marking designs These include:

The overall market size for Industrial Marking Equipment Market was USD 34.1 Billion in 2025.

The Industrial Marking Equipment Market is expected to reach USD 54.6 Billion in 2035.

The demand for the industrial marking equipment market will grow due to increasing regulations on product traceability, rising adoption in manufacturing and packaging industries, advancements in laser and inkjet marking technologies, and the growing need for durable and high-precision marking solutions.

The top 5 countries which drives the development of Industrial Marking Equipment Market are USA, UK, Europe Union, Japan and South Korea.

Automotive and Electronics & Semiconductors Drive Market to command significant share over the assessment period.

Automated Material Handling Systems Market - Market Outlook 2025 to 2035

Industrial Vacuum Evaporation Systems Market Analysis - Size & Industry Trends 2025 to 2035

Industrial Temperature Controller Market Analysis - Size & Industry Trends 2025 to 2035

Domestic Booster Pumps Market Growth - Trends, Demand & Innovations 2025 to 2035

Condition Monitoring Service Market Growth - Trends, Demand & Innovations 2025 to 2035

Industrial Robotic Motors Market Analysis - Size & Industry Trends 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.