The industrial drum market is experiencing robust growth as businesses prioritize durable, reusable, and cost-effective solutions for the storage and transportation of bulk materials. Manufacturers are innovating with advanced materials, ergonomic designs, and eco-friendly production methods to meet the demands of chemical, food, pharmaceutical, and logistics industries. By 2035, this market is projected to exceed USD 21.4 billion, growing at a compound annual growth rate (CAGR) of 5.1%.

The increasing emphasis on operational efficiency, sustainability, and regulatory compliance is driving global adoption of industrial drums. Companies are delivering solutions that enhance durability, environmental responsibility, and adaptability to diverse applications

| Attribute | Details |

|---|---|

| Projected Value by 2035 | USD 21.4 billion |

| CAGR (2025 to 2035) | 5.1% |

Explore FMI!

Book a free demo

Summary

This SWOT analysis highlights the strengths, weaknesses, opportunities, and threats faced by leading players in the industrial drum market. Companies like Greif Inc., Schutz GmbH, and Mauser Group leverage innovation, sustainability initiatives, and robust distribution networks to sustain their leadership. Challenges such as fluctuating raw material costs and regional competition create opportunities for advancements in sustainable materials and global expansion.

Greif Inc.

Greif Inc. leads the market with its durable and customizable industrial drum solutions. Its strength lies in its global presence and focus on sustainability. However, high production costs for advanced designs pose a challenge. Opportunities include developing eco-friendly drum designs and penetrating emerging markets, while competition from regional players remains a threat.

Schutz GmbH

Schutz GmbH excels in delivering lightweight, reusable industrial drums. The company’s strong focus on innovation and recycling initiatives gives it a competitive edge. However, limited market penetration in certain regions could hinder growth. Opportunities lie in expanding into Asia-Pacific and enhancing drum recycling technologies, while evolving regulations may impact operations.

Mauser Group

Mauser Group is renowned for its robust, multi-functional drum designs that cater to diverse industries. The company’s strong R&D capabilities and focus on eco-friendly materials make it a trusted name. However, premium pricing for advanced drums may limit its reach in price-sensitive markets. Opportunities exist in developing smart drums, while raw material price volatility remains a challenge.

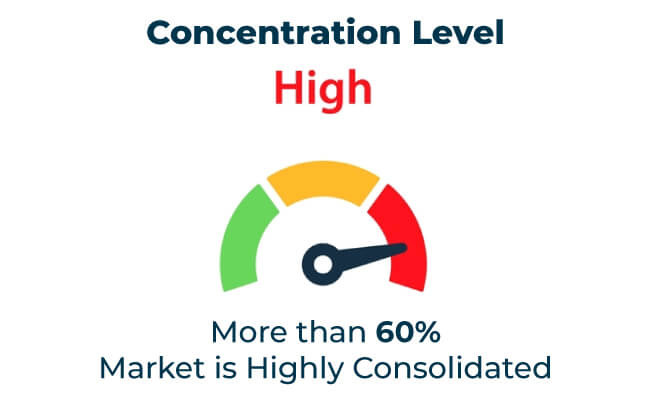

| Category | Market Share (%) |

|---|---|

| Top 3 Players (Greif Inc., Schutz GmbH, Mauser Group) | 17% |

| Rest of Top 5 Players (Industrial Container Services, Time Technoplast) | 9% |

| Next 5 of Top 10 Players | 6% |

Type of Player & Industry Share

| Type of Player | Market Share (%) |

|---|---|

| Top 10 Players | 32% |

| Next 20 Players | 38% |

| Remaining Players | 30% |

North America enforces strict safety and environmental regulations, driving innovation in recyclable and durable industrial drums. Europe leads with policies promoting sustainability and multi-functional drum designs. Asia-Pacific is witnessing rapid growth due to increased demand from chemical and food sectors, offering opportunities for innovative solutions tailored to regional needs.

Emerging markets in Asia-Pacific, Africa, and Latin America present significant growth potential. The expansion of industries such as chemicals, food, and pharmaceuticals in these regions drives demand for high-quality industrial drums. Exporters focusing on compliance and sustainability can seize these opportunities to expand their footprint.

The regional analysis of the industrial drum market reveals growth trends shaped by regulatory compliance, sustainability goals, and industrial applications. Each region offers unique opportunities for manufacturers to align their solutions with local market demands.

| Region | North America |

|---|---|

| Market Share (%) | 40% |

| Key Drivers | Focuses on durability, safety, and regulatory compliance. |

| Region | Europe |

|---|---|

| Market Share (%) | 35% |

| Key Drivers | Leads with advanced sustainability initiatives and innovative designs. |

| Region | Asia-Pacific |

|---|---|

| Market Share (%) | 20% |

| Key Drivers | Experiences rapid growth due to industrial expansion and exports. |

| Region | Other Regions |

|---|---|

| Market Share (%) | 5% |

| Key Drivers | Demand grows for cost-effective, durable solutions in emerging markets |

The industrial drum market will continue to grow through advancements in smart technologies, sustainable materials, and ergonomic designs. Companies focusing on global expansion, compliance with regulations, and innovative product offerings will strengthen their market positions. Collaboration with end-users and policymakers will further drive adoption.

Summary

This section provides a detailed breakdown of the key players in the industrial drum market by tier. Tier 1 companies like Greif Inc., Schutz GmbH, and Mauser Group lead with innovative, eco-friendly solutions and strong global presence. Tier 2 and Tier 3 players focus on niche applications and regional dominance, offering opportunities for growth through innovation and sustainability.

| Tier | Key Companies |

|---|---|

| Tier 1 | Greif Inc., Schutz GmbH, Mauser Group |

| Tier 2 | Industrial Container Services, Time Technoplast |

| Tier 3 | Skolnik Industries, Balmer Lawrie |

The industrial drum market is positioned for steady growth as sustainability, durability, and industrial demand drive adoption. Companies prioritizing innovative designs, eco-friendly materials, and global market expansion will lead the industry. Collaboration with stakeholders in chemicals, food, and logistics will unlock new opportunities.

Key Definitions

Abbreviations

Methodology

This report integrates primary research, secondary data, and expert insights. Findings are validated through interviews with industry professionals and end-users to ensure accuracy and reliability.

The industrial drum market includes the development and application of durable containers designed to store and transport bulk materials efficiently and sustainably. These drums prioritize durability, safety, and environmental responsibility.

Industrial drums are used to store and transport bulk materials safely, including chemicals, food, and pharmaceuticals.

Manufacturers design drums with recyclable and reusable materials while adopting energy-efficient production methods to minimize environmental impact.

North America and Europe lead due to stringent compliance standards and advanced manufacturing capabilities, while Asia-Pacific is rapidly growing.

High material costs, regulatory complexities, and limited recycling infrastructure are key challenges in the industrial drum market.

Paper Loading Machine Market Trend Analysis Based on Product, End-Use, Loading Mechanism, Machine Size/Capacity, Automation Level and Regions 2025 to 2035

Case Closures and Sealers Market Growth – Demand & Forecast 2025 to 2035

Cannabis Packaging Equipment Market Growth – Forecast 2025 to 2035

Cassava Bags Market Growth – Demand & Forecast 2025 to 2035

Butcher Paper Market Insights – Growth & Demand Forecast 2025 to 2035

UV Stabilized Films Market Analysis by Product Type, Material, Thickness, Technology, Application, End-Use Industry, and Region through 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.