The in-mold label (IML) market is experiencing significant growth as industries seek efficient, durable, and visually appealing labeling solutions. These labels, integrated directly into packaging during the molding process, are widely used in food, beverages, personal care, and industrial applications due to their superior aesthetics, durability, and cost-effectiveness.

By 2035, the market is projected to reach USD 1494.5 million, growing at a compound annual growth rate (CAGR) of 2.8%. Key growth drivers include advancements in packaging technology, increasing demand for premium product branding, and sustainability initiatives.

| Attribute | Details |

|---|---|

| Projected Value by 2035 | USD 1494.5 Million |

| CAGR during the period 2025 to 2035 | 2.8% |

Manufacturers are focusing on innovative label designs, recyclable materials, and automation in production processes. Collaborations with packaging and consumer goods companies ensure alignment with market demands and regulatory goals.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

Factors Driving Market Growth

The in-mold label market is driven by several key trends:

| Category | Market Share (%) |

|---|---|

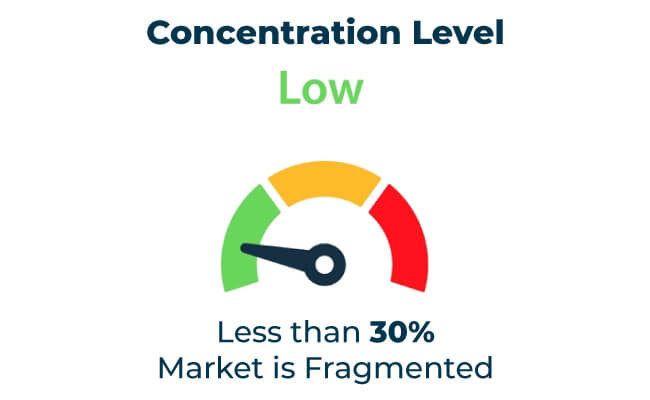

| Top 3 Players (CCL Industries, Huhtamaki, Constantia Flexibles) | 12% |

| Rest of Top 5 Players (Multi-Color Corporation, Coveris) | 06% |

| Next 5 of Top 10 Players | 8% |

Type of Player & Industry Share (%)

| Type of Player | Market Share (%) |

|---|---|

| Top 10 Players | 26% |

| Next 20 Players | 20% |

| Remaining Players | 34% |

Low concentration highlights the industry to be fragmented setting a competitive environemnt with room for emerging players to innovate and grow.

Year-on-Year Leaders

Check Free Sample Report & Save 40%!

Select your niche segments and personalize your insights for smart savings. Cut costs now!

Emerging regions such as Asia-Pacific, Africa, and South America present significant growth potential. Scalable and cost-effective IML solutions are in high demand.

In-House vs. Contract Manufacturing

| Region | North America |

|---|---|

| Market Share (%) | 35% |

| Key Drivers | Strong focus on premium branding and sustainable solutions. |

| Region | Europe |

|---|---|

| Market Share (%) | 30% |

| Key Drivers | Sustainability regulations and advanced manufacturing. |

| Region | Asia-Pacific |

|---|---|

| Market Share (%) | 25% |

| Key Drivers | Growth in consumer goods and packaging industries. |

| Region | Other Regions |

|---|---|

| Market Share (%) | 10% |

| Key Drivers | Demand for affordable and durable labeling solutions. |

The in-mold label market will advance through innovations in material science, digital printing, and sustainable practices. Companies prioritizing eco-friendly solutions and enhanced functionality will lead the market.

| Tier | Key Companies |

|---|---|

| Tier 1 | CCL Industries, Huhtamaki, Constantia Flexibles |

| Tier 2 | Multi-Color Corporation, Coveris |

| Tier 3 | Inland Packaging, EVCO Plastics |

The in-mold label market is poised for significant growth, driven by advancements in packaging technology, sustainability initiatives, and demand for premium branding. Companies investing in innovative designs and eco-friendly practices will secure a competitive edge.

Key Definitions

Abbreviations

Research Methodology

This report is based on primary research, secondary data analysis, and market modeling, validated through industry expert consultations.

Market Definition

The in-mold label market encompasses solutions for food, beverages, personal care, and industrial applications, focusing on innovation, branding, and sustainability.

Advancements in packaging technology, sustainability initiatives, and rising demand for premium branding drive growth.

The market is projected to reach USD 1494.5 million, growing at a compound annual growth rate (CAGR) of 2.8%.

CCL Industries, Huhtamaki, and Constantia Flexibles are among the leading companies.

High initial investment, technical challenges, and recycling infrastructure limitations are key challenges.

Opportunities include growth in premium packaging, technological innovations, and increased consumer demand for sustainability-focused solutions.

Explore Tech in Packaging Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.