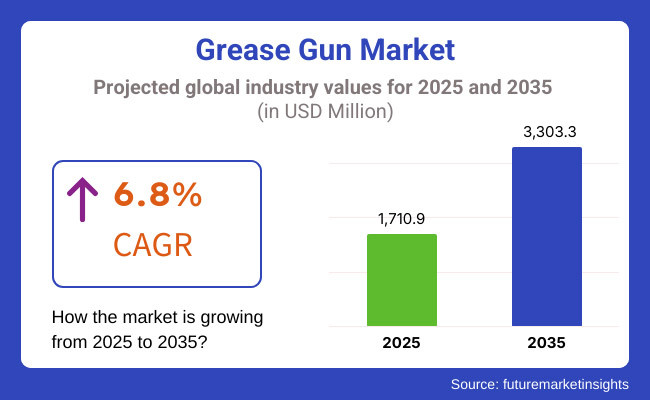

The Grease Gun Market is projected to grow from USD 1,710.9 million in 2025 to USD 3,303.3 million by 2035, reflecting a CAGR of 6.8% over the forecast period. The market is expanding due to rising demand for effective lubrication systems in industrial machinery, automotive maintenance, and heavy equipment servicing.

Grease guns are pivotal for the decline of friction, enhanced machinery life-expectancy, and preventing mechanical failures in many industries such as manufacturing, agriculture, construction, and transportation. Besides, the growth of the market alarmed the adoption of the automated lubrication solutions, cordless grease guns, and precision dispensing technologies is further fuelling the enhancing efficiency and reducing maintenance costs.

The continuous pursuit of preventive maintenance and added machinery perfection is the engine of grease guns across various industries. The increasing use of battery-operated and pneumatic grease guns is the reason lubrication precision and comfort have developed very strongly especially in high-performance automotive and industrial applications.

Technological advancements such as smart grease guns that have digital monitoring systems are the talk of the town because they help the operators to track the grease levels, pressure, and dispensing accuracy in real-time. What's more, the sustainability issues are the driving force for the innovation of eco-friendly lubricants and grease dispensing technologies that create less waste and have less environmental impact.

The increasing automation in the industry, the size of the automotive aftermarket sector, and the necessity for tooling that is efficient in lubrication in heavy-duty applications all are the key factors that are shaping the market's perspective.

Explore FMI!

Book a free demo

The North American grease gun market increases remarkably owing to the rise of the automotive sector, industrial automation, and infrastructure development.The USA and Canada are among the countries where advanced lubrication solutions are primarily used in heavy equipment, vehicle repair, and aerospace.

The main factor stimulating the market is the implementation of the new technology of battery-operated grease guns which are used for exact lubrication and it also reduces the manual effort. Nevertheless, the imposition of regulatory constraints on the industrial lubricant emission and the competition which is presented by the automated lubrication systems can be the major reasons for the market stalling. The integration of IoT in the smart grease guns is expected to increase industrial maintenance efficiency and improve monitoring.

The European grease gun market's growth is attributed to strict maintenance machinery requirements, more automated manufacturing processes, and the rise of electric vehicles (EVs). Countries like Germany, France, and the UK are interested in increasing industrial efficiency and developing sustainable maintenance solutions thus increasing demand for precision lubrication tools.

The increase in wind energy production and railway maintenance projects have also helped the market. However, strict environmental regulations regarding lubricant disposal and lubricant systems changing to be completely automated, are seen as the major challenges. The application of biodegradable lubricants as well as intelligent grease guns is a significant factor that helps companies in achieving their sustainability goals.

The Asia-Pacific region is the grease gun market that is growing the fastest with the help of the industrial boom, the automobile sector, and the agricultural sector and Ja are the top heavy machinery and vehicle maintenance manufacturing and are thus meeting the needs of mechanical and pneumatic grease guns.

The growth of mining, construction, and smart factories is the leading to the high demand of lubrication equipment that use less energy. Problems like increasing raw material costs and fake products may hinder the overall development of the market. The adoption of automated lubrication systems and improved grease keys technologies are the region's solutions to raise productivity and cut down equipment downtime.

The Middle East & Africa's (MEA) market is generating money through oil & gas due to increased government investment in infrastructure projects, and the servicing of heavy equipment. Countries like Saudi Arabia, the UAE, and South Africa are seeing the need for industrial lubrication tools rise in sectors such as energy, mining, and transportation. The fact that large machines are being used in drilling, refining, and logistics is somehow the reason for the rise in the need for grease guns.

The key problems that are encountered are the economic downturn and reliance on imported equipment. The area is characterized by such things as high-performance, corrosion-free grease guns and the implementation of automated lubrication systems, which are looked upon as the growth factors in the business.

The grease gun market in Latin America is boosted by the growing automotive sector, mining industry, and farm sector which is expanding. The countries like Brazil, Mexico, and Argentina are signing deals for the industrial development and equipment amelioration that will perpetuate the use of superior grease dispensing gadgets.

Government programs which support mechanized farming projects as well as initiatives on industrial automation assist largely in the cause of market growth. However, the problems such as frequent economic fluctuations, import duties being sky-high, and the difficulty in obtaining modern lubrication technologies may obstruct development. The growth of aftermarket maintenance services and digital lubrication monitoring systems gives a new range of opportunities for market players.

Challenges

Adoption of Automated Lubrication Systems

The rise of automated lubrication systems in industrial plants, construction machinery, and heavy equipment is reducing reliance on manual grease guns. These systems offer real-time monitoring, precise lubrication, and reduced maintenance effort, making them a preferred choice for large-scale operations. As industries transition toward fully automated and centralized lubrication, demand for traditional grease guns may decline.

However, manual grease guns remain relevant in smaller-scale applications, field operations, and maintenance tasks requiring portability. Manufacturers must innovate with smart and efficient grease guns to compete with the increasing preference for automated lubrication solutions in industrial maintenance.

Stringent Environmental Regulations on Lubricant Use

Governments worldwide are enforcing strict regulations on grease disposal, workplace safety, and lubricant emissions to minimize environmental impact. Restrictions on hazardous grease compounds and excessive lubricant waste require manufacturers to develop biodegradable, low-emission lubrication solutions.

Compliance with sustainability policies and industrial safety standards increases R&D costs and regulatory burdens for grease gun manufacturers. Companies must invest in eco-friendly grease dispensing technologies while ensuring product efficiency and cost-effectiveness. While these regulations create challenges, they also encourage the development of next-generation grease guns with controlled dispensing and environmentally friendly lubrication technologies to meet sustainability goals.

Fluctuating Raw Material Prices

The production of grease guns relies on steel, aluminum, plastics, and electronic components, all of which are subject to price fluctuations and supply chain disruptions. Trade restrictions, geopolitical tensions, and raw material shortages can impact manufacturing costs, product pricing, and profit margins.

The volatility in global markets makes it difficult for manufacturers to stabilize production expenses and maintain competitive pricing. Companies must adopt cost-efficient sourcing strategies, invest in recyclable materials, and optimize manufacturing processes to mitigate these challenges. Additionally, fluctuating fuel prices and transportation costs further influence supply chain dynamics, affecting the availability and affordability of grease guns.

Opportunities

The Incorporation of Smart Grease Guns

The introduction of IoT-enabled grease guns, digital tracking systems, and AI-driven lubrication monitoring is revolutionizing the industry. Smart grease guns help users to measure grease consumption, pressure levels, and lubrication cycles accurately, thus, making it possible to cut down on overuse, waste, and mechanical failures.

The wireless connection and diagnostic tools in real time let maintenance teams achieve optimal lubrication schedules, augment equipment life, and lower downtime. Alongside industries that are progressing toward predictive maintenance and automated monitoring, smart grease guns deliver a competitive edge. Manufacturers that spend on digital pathfinders, sensor-adapted grease guns, and cloud lubricating management will be to a great extent successful and will have very strong future prospects.

The Automotive, Construction, and Industrial Sectors on the Rise

The increasing demand for effective lubrication in the automotive sector, heavy machinery, and industrial automation is the primary source of growth for grease guns. The rising number of global infrastructure projects, cutting-edge factories, and mining operations that necessitate state-of-the-art lubrication tools to increase machinery efficiency and detract from mechanical failures is the cautious but optimistic sign as of now.

The automotive sector, particularly making electric and hybrid vehicles, is predominantly the one that is undertaking precision lubrication in the use of bearings, chassis components, and drivetrain systems. The ongoing expansion of high-performance, preventive maintenance machinery via newcomers into the industry will facilitate the durability and quality increase of grease .

The Idea of Battery-Operated and Cordless Grease Guns Gaining Popularity

The battery-operated grease guns are making work easier and increasing productivity in all entities due to their compact nature and use of technologies that are wireless. Battery-driven grease guns are freed from human inputs as they deliver a regular grease flow and control the pressure of grease making them useful during field work for mechanics, industrial technicians, and operations.

A new initiative for developing lithium-ion battery-powered, lighter, and more usable grease guns has been introduced as this will allow longer hours of work and improved mobility in workshops, construction sites, and agricultural applications. As industries are looking for more efficient and labor-saving solutions for lubrication, manufacturers who focus on ergonomic and high-performance cordless grease guns will take a major part in the market growth.

The grease gun market has been on a continuous upward trend during 2020 to 2024 due to the rise in automotive maintenance, industrial machines, and heavy equipment lubrication.

The quest for additional years of machine life and lower downtime caused the evolution of grease gun technologies. Battery and pneumatic grease guns have been in the spotlight because they are both simple and very effective in large volume applications. The market is expected to be home to the rise of intelligent lubricating systems and automated dispensing of environmentally safe grease alongside the traditional developments in automation.

Comparative Market Analysis:

| Market Shift | 2020 to 2024 |

|---|---|

| Regulatory Landscape | Occupational safety regulations and efficiency standards for lubrication equipment. |

| Technological Advancements | Adoption of battery-powered, pneumatic, and lever-action grease guns for improved efficiency. |

| Industry-Specific Demand | Demand driven by automotive, construction, agriculture, and industrial machinery maintenance. |

| Sustainability & Circular Economy | Initial efforts to reduce grease waste and improve dispensing efficiency. |

| Production & Supply Chain | Stable manufacturing and supply chain with a focus on durable materials and performance. |

| Market Growth Drivers | Rising demand for preventive maintenance, industrial automation, and extended equipment lifespan. |

| Market Shift | 2025 to 2035 |

|---|---|

| Regulatory Landscape | Stricter environmental regulations promoting biodegradable lubricants and energy-efficient tools. |

| Technological Advancements | Smart grease guns with IoT connectivity, automated lubrication systems, and AI-driven maintenance scheduling. |

| Industry-Specific Demand | Expansion into precision lubrication for robotics, electric vehicles, and renewable energy infrastructure. |

| Sustainability & Circular Economy | Increased focus on eco-friendly lubricants, recyclable grease cartridges, and waste-reduction technologies. |

| Production & Supply Chain | AI-driven supply chain optimization, localized production, and advancements in material sustainability. |

| Market Growth Drivers | Integration of smart lubrication, predictive maintenance solutions, and the transition to sustainable lubrication practices. |

The market for grease guns in the United States is constantly on the rise due to the rapid industrialization, automotive maintenance, and construction sector development. The installation of automated lubrication systems into manufacturing and heavy industries is the prime reason behind the increasing demand.

Moreover, the surge in preventive maintenance practices by industries to extend the service life of machines has led to the rise of battery-operated and pneumatic grease guns. The agriculture sector, with its vast farm machinery and need for frequent lubrication, is also a major contributor to the market's growth. The ongoing trend of seeking more efficient and ecological lubrication means has continuously spurred innovations in the preload grease dispenser technology.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 6.9% |

The grease gun market in the UK is progressing rapidly due to the globalization of the industrial sector and increasing vehicle maintenance needs as well as the growing automation in manufacturing facilities. The increasing number of commercial vehicles and machines in the logistics and transport sectors is the driving force for ventilation equipment.

The use of green lubricants and precision lubrication equipment, which meet the environmental standards, further helps the market growth. The introduction of the electronic grease dispenser to other industrial plants is also a contributor to the market demand. The automotive workshop is creating a huge demand for grease guns because of the increased requirement of vehicle maintenance.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 6.6% |

The Grease Gun Market in the European Union is seeing a rapid surge in sales owing to the focus on the industrial sector's efficiency, automotive developments, and the use of lubrication technologies. The leading countries in the implementation of high-tech and high-precision lubrication equipment are Germany, France, and Italy.

The growing automotive, construction, and heavy equipment sectors are the main drivers for the rise of battery-operated and pneumatic grease guns. Moreover, the EU statutes on low-emission lubricants are seen as the driving force behind the new development in the field of environment-friendly lubrication products.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union | 6.7% |

The grease gun market in China is surging high because of the ongoing industrialization and the infrastructural and vehicle developments. The auto industry in China, which is on the verge of expansion with more and more passenger and commercial vehicles being manufactured, is one of the main causes this automated lubrication tool demand.

Also, the construction, mining, and heavy machinery sectors that are growing are the other main reasons behind market expandtion. Precision grease guns are one of the high demands because of the implementation of new lubrication technologies in the manufacturing plants and in the manufacturing processes. The mechanization of the agricultural sector also plays a role in the expansion of the market.

| Country | CAGR (2025 to 2035) |

|---|---|

| China | 7.2% |

The major factors for the growth of the Japan Grease Gun Market are its technological development in manufacturing, automotive innovation, and the use of high-performance lubrication tools. Moreover, the industrial efficiency and robotics concentrate of Japan are the bases for the need of automated grease dispensing systems.

The population is aging and the laborers are not enough which is driving the change to battery-powered and automated lubrication systems even more. Also, the automotive sector, which has a strong presence in Japan, relies on precision engineering which contributes to high lubricant guns.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 6.5% |

The South Korea Grease Gun Market is prospering with the increase in automotive manufacturing, industrial automation, and heavy machinery sectors. Being one of the main car manufacturers, South Korea's automotive industry is obviously the main force pushing demand for the modern lubrication tools.

Besides, rapid development in the international smart factory associating with the robotics and robotics is promoting the installation of the automated lubrication solutions. Encountering with this the construction and agriculture equipment sector is also dealing with the demand for the high-performance grease guns that are available in the market.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 6.8% |

Introducing the Cost-Effective Lubrication Solutions for the Bulk Loading Segment

The segment for bulk loading has taken the first position in the grease gun market share due to its cost efficiency and high-volume lubrication needs. The automotive, construction, and agricultural sectors have bulk-loaded grease guns at the top of their lists because they allow for one-time large-scale lubrication without need to frequently replace cartridges.

This is particularly used in the maintenance of heavy machinery and in industrial settings where f continuous lubrication is required to decrease friction and prolong the life of the machines. Besides, the bulk loading can be messy and time-consuming, and that eventually leads some users to move toward the cartridge-based way for cleaner and faster grease replenishment.

The cartridge loading segment is gaining more and more popularity because of its clean and convenient Operating

The cartridge loading segment is showing the increasing trend of being mostly adopted since it is simple to operate, has a little mess, and a quick refilling process. It is mainly used in car repair workshops, small-scale industrial maintenance, and construction equipment servicing, where convenience is the priority and downtime is minimized.

The increasing number of pre-filled grease cartridges in various formulations is the very reason why this method is so attractive for technicians and mobile service providers. Furthermore, the environmental concern relates grease wastage and contamination to the reason for which industries shift to the cartridge-based systems that provide the requisite accurate and spill-free lubrication.

The Manual Lever Segment is the Top Player with Affordability and Portability

The manual lever grease gun segment holds the number one spot in the market mainly due to its affordability, durability, and is very user-friendly. These grease guns are mainly used in small workshops, automotive repairs, and light industrial maintenance where the lubrication needs are medium.

The lack of a power source line along with the wrong manual grease guns makes them highly portable and suitable in situations where a person is on the field in agriculture, construction, and fleet maintenance. However, to add to these two points, another thing is also thoughtful: it is slow delivery rates that can also be a limiting factor if these units are high-duty ones which is the reason for shift towards pneumatic and battery-powered alternatives.

Demand for High-Volume Lubrication Pushes the Pneumatic Grease Guns into the Main Stage

The pneumatic grease gun segment has been a witness to a surge in rates of adoptions. In industrial plants, heavy machinery servicing, and large vehicle maintenance, high-pressure lubrication is the requirement. These grease guns work with the aid of compressed air which indeed, contributes to the speed and application efficiency with less physical effort. In that sense, pneumatic grease guns are a must-have tool in the construction and mining sectors as they are used for enormous bearings, gears, and hydraulic components. Then again, connecting to an air compressor and a hose might decrease pneumatic units' portability compared to manual and battery-powered ones.

The Automotive Industry Takes the Lead on the Market with its Continuous Lubricant Needs

The automotive industry holds the foremost position and is the biggest customer of grease guns driven by the steady lubrication requirements of the engine parts, chassis, and wheel bearings. Grease guns are crucial tools used for preventive maintenance not only in the service centers but also in the manufacturing plants and fleet management operations.

The introduction of electric vehicles (EVs) brings along spec grease formulations for the new style of high насос performance which is necessary for battery-cooling systems thus giving rise to the development of the latest lubrication technology. On the other hand, the increase in the number of ride-sharing fleets and the commercial vehicle maintenance services is the driving factor for the demand of high-efficiency grease guns in the sector.

The Construction Industry Sees The Increased Demand for Heavy Machinery Maintenance

The construction industry is largely dependent on the grease guns acquired for the maintenance of the excavators, bulldozers, cranes, and other heavy equipment. Correct lubrication is necessary to prevent wear and tear costs on moving parts, reduce the time of downtime, and enhance the lifespan of the equipment.

Wherever the construction sector sees growth worldwide due to the infrastructure projects, there is a note of demand increase for pneumatic and battery-powered, which are mostly high pressure, grease guns to improve efficiency during the lubrication of hydraulic and other structural components.

The Grease Gun Market is growing steadily, driven by rising demand for efficient lubrication tools in automotive, construction, industrial, and agricultural sectors. Grease guns play a crucial role in machinery maintenance, reducing friction, and extending equipment lifespan. The market is witnessing technological advancements, particularly in battery-powered and pneumatic grease guns, which offer higher efficiency, precise grease application, and reduced manual effort.

Increasing industrial automation and the need for preventive maintenance solutions are further fueling market growth. Manufacturers are focusing on ergonomic designs, high-pressure delivery systems, and smart grease monitoring to enhance performance. The push for sustainable and eco-friendly lubrication solutions is also influencing innovation in the market.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Lincoln Industrial (SKF Group) | 18-22% |

| Dewalt (Stanley Black & Decker) | 12-15% |

| Milwaukee Tool (Techtronic Industries) | 10-13% |

| Makita Corporation | 7-9% |

| Plews & Edelmann | 5-7% |

| Other Companies (combined) | 35-45% |

| Company Name | Key Offerings/Activities |

|---|---|

| Lincoln Industrial (SKF Group) | Leading supplier of manual, pneumatic, and battery-powered grease guns for industrial applications. |

| Dewalt (Stanley Black & Decker) | Develops high-pressure cordless grease guns with advanced battery technology and ergonomic designs. |

| Milwaukee Tool (Techtronic Industries) | Offers M18™ battery-powered grease guns with digital pressure control and LED indicators. |

| Makita Corporation | Specializes in compact, lightweight grease guns for precision lubrication in industrial settings. |

| Plews & Edelmann | Provides affordable, manual grease guns for DIY and small-scale industrial applications. |

Key Company Insights

Lincoln Industrial (SKF Group)

Lincoln Industrial, a component of SKF Group, stands out as a global forerunner in lubrication tools and systems, including the manual, pneumatic, and battery-operated grease guns for a myriad of industrial applications.

The company’s PowerLuber™ series product has the company with ultra-high-pressure pumping capacity, automatic grease flow monitoring, and user-friendly construction. Lincoln is now turning its attention to the wireless mode of lubrication and the internet of things enabled maintenance solutions. This ensures grease wastage is minimal, whether the equipment is running continuously or intermittently.

The high-performance automotive, construction, and heavy machinery industries are some of the main sectors where Lincoln is present, and it still pushes the boundaries of technology with the launch of sophisticated lubrication systems, thus contributing to higher efficiency, safety, and performance in extreme environmental conditions.

Dewalt (Stanley Black & Decker)

Dewalt is a brand of Stanley Black & Decker that is good at the production of high-performance grease guns operating on battery power and designed for the use in the automotive, industrial, and heavy equipment maintenance sectors. The 20V MAX grease gun featuring the Dewalt logo is both practical and user-friendly as it comes with variable speed control, high-pressure output, and LED lighting that allows it to work efficiently under low-light conditions.

Dewalt is linking brushless motor technology with lithium-ion battery development through the introduction of longer-than-ever runtime, redundancy, and, of course, significant maintenance savings. Dewalt is a solid brand that always comes to mind for the robust, job-site-ready instruments that are associated with. The firm is now presenting a new line of smart lubrication systems that will be simpler to use, more ergonomic for the operator, and will provide more accurate grease application.

Milwaukee Tool (Techtronic Industries)

Milwaukee Tool is at the forefront of the production of battery-operated lubrication tools. It has two models: the M12™ and M18™ grease guns, both featuring the digital control, REDLINK™ intelligence, and good ergonomics. The manufacturer prioritizes innovative lubrication solutions, such as automatic monitoring through IoT and grease flow regulation for the efficient maintenance of machinery.

Milwaukee grease guns are characterized by high-power output, long battery life, and sturdy design which makes them the preferred choice among construction, heavy equipment, and industrial applications. They've got the cutting-edge engineering, digitized communication, and advanced power tools innovations to thank for being the auto-lube system leader.

Makita Corporation

Makita has become a notable company in the lightweight, battery-powered grease gun market, focusing on Windfield precision lubrication tools for industrial and automotive maintenance. They, in turn, design low-noise, high-efficiency products since they are the ones responsible for developing ergonomic cordless grease guns that are very user-friendly in small and hard-to-reach areas.

Makita has launched a range of portable, high-pressure grease guns that tackle the trade-off of a longer battery life against faster grease delivery through a rigorous user-friendly program. Also, the company is committed to drive the innovation of power tools and equipment in the industrial sector, adding brushless motor technology and batteries with greater efficiency into their line that makes it possible to provide long-lasting, pest-free, and energy-efficient lubrication techniques in multiple fields of expertise.

Plews & Edelmann

Plews & Edelmann has a solid reputation as a manufacturer of economic manual and lever-action grease guns targeted towards DIY users, small workshops, and agriculture applications. The firm relies on durable and low-cost designs to become the go-to product in small and starter-level industries it is often used in assembly and repair settings.

Plews & Edelmann grease guns are affordable and straightforward tools for lubrication; they are easy to use and last long which means they are reliable. These days, pneumatic and manual lubrication tools are becoming more popular, therefore, the firm is continually releasing highly resilient, high-end grease guns while diversifying into the development of lubrication accessories and users' needs maintenance.

The global Grease Gun market is projected to reach USD 1,710.9 million by the end of 2025.

The market is anticipated to grow at a CAGR of 6.8% over the forecast period.

By 2035, the Grease Gun market is expected to reach USD 3,303.3 million.

The manual grease gun segment is expected to dominate due to its cost-effectiveness, ease of use, and widespread application in automotive and industrial maintenance.

Key players in the Grease Gun market include Lincoln Industrial, Dewalt, Macnaught, SKF, Milwaukee Tool, and Plews & Edelmann.

Surge Tanks Market Growth - Trends & Forecast 2025 to 2035

Radial Drilling Machine Market Growth & Demand 2025 to 2035

External Combustion Engine Market Growth & Demand 2025 to 2035

Motor Winding Repair Service Market Growth - Trends & Forecast 2025 to 2035

Industrial Linear Accelerator Market Growth & Demand 2025 to 2035

Vision Guided Robots Market - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.