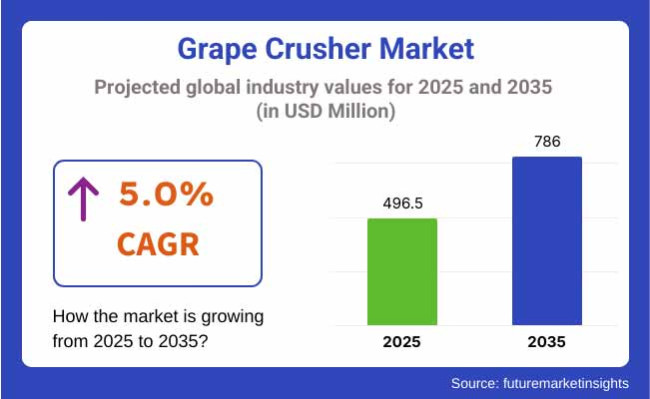

The grape crusher market was valued at USD 456.7 Million in 2023, and by 2025, the international market value was reached USD 496.5 million. During this period, it is expected that global sales will increase at an approximate 5.0% CAGR, closing in at a market worth USD 786 million at the end of 2035.

The grape crusher market is driven by the growing demand for the production of wine across the globe. As vineyards continue to be planted and wineries are buying high-tech processing equipment, they want modern grape crushers for the job. Automated and electric grape crushers are swiftly gaining ground for both their efficiency and consistency and also for their labour-saving benefits, but the trial and error aspect of their design does not go unnoticed.

Furthermore, mechanical innovations are made like pneumatic and hydraulic crushers are more utilized. They ensure precise pressure control, which enhances juice extraction and helps to prevent seed breakage, which can cause bitter flavors in the resultant wine.

Furthermore, sustainability trends in viticulture contribute to the transition to the use of environmentally friendly and energy-efficient models of the equipment. To sustain a better market outlook, market blockers have been discussed in this report and how these blockers will impact global market growth has also been covered in this report.

The Global Grape Crusher Industry over 6 months This analysis helps to underscore the degree of difference in performance and enables stakeholders to assess revenue-generating momentum for the year.

| Particular | Value CAGR |

|---|---|

| H1 (2024 to 2034) | 4.4% |

| H2 (2024 to 2034) | 4.7% |

| H1 (2025 to 2035) | 5.2% |

| H2 (2025 to 2035) | 5.5% |

The growth in the grape crusher market is 5.2% from 2025 to 2035 (H1) and it is anticipated to retain the growth rate at 5.5% from 2025 to 2035 (H2). The market is likely to grow as new wineries are continuously opened for establishment during this time period, due to the growing investment in wine production up to October 2023 as well as the increasing preference for boutique wineries and home wine making.

In this regard, automation hydraulic and pneumatic grape crushers are developed and being used in order to achieve high juice yield, high crushing quality, greatly reducing breaking seeds, thus, improving quality of wine automation hydraulic and pneumatic grape crushers. All types of crushers can be energy-efficient and environmentally friendly, to comply with sustainable winemaking principles.

With the increasing demands to optimise productivity and cut down on labour costs, vineyards have been increasingly gravitating towards performance heavy, automation driven systems for crushing. Growing such creative productions in tandem with the marketplace on an international scale in the wine market will be two of the most valuable elements of public relations over the next decade, and a key public relations success story for each of the organizations and events around the world.

Tier 1: The most competitive set of companies alongside Tier 1 companies dominate the grape crusher market with high revenue generation, market share, and global presence. These companies enjoy and invest heavily in R&D, advertising and product development and maintain considerable brand equity as well.

High-performance, automated grape crushers are highly recognized among global players like Zambelli Enotech, Bucher Vaslin, and Pellenc Group. Its extensive distribution networks and technological expertise allows it to serve large-scale wineries and commercial growers. These companies prioritize the efficiencies, durability, and precision required for industrial-size wine production.

Tier 2 represents mid-revenue companies that maintain strong market presence. The prices in this range make them suitable for medium-sized wineries and small vineyards, brands such as Enoitalia, Rauch GmbH, Amos Industrie, etc. Their equipment is appealing to developing wine producers because these companies emphasize cost and adaptability. Their approach is predicated on affordability alongside effective performance, allowing them to achieve significant market stability.

Tier 3 as emerging players and smaller manufacturers where they continue to attract market share with niche, creative and highly cost-effective solutions. Firms like Marchisio and Grifo Marchetti sell manual and small electric grape crushers aimed at home winemakers and boutique wineries.

These brands emphasize affordability, simplicity, and ease of use, appealing to the hobbyist and artisanal wine segments. They often employ strategies that include direct sales, social media, local distribution channels, and niche marketing to compete directly with bigger companies by addressing specialized consumer needs.

Recruitment process will be two-way automation and two-way efficiency.

Shift: The demand for high-efficiency and automated crushers is expected to rise in the grape crusher space owing to the need for improved productivity, repeatability and reduced dependence on labor. These are, for example, hydraulic, pneumatic and sensor-based automated grape-crushers to start with, allowing for more accurate crushing control, extraction of more juice and reduction of crushed seed.

This is evident by the demand for fully automated crushing lines in high scale commercial wineries found in the Italy, France, USA, and Australia where speed and consistency are primary concerns. The trend towards smart solutions is being also realized at the crushing level, where IoT-powered solutions for remote monitoring and predictive maintenance continue to reduce downtime.

Strategic Response: To combat this trend, Bucher Vaslin introduced its Delta series of auto de-stemmers and adjustable crushing rollers, maintaining grape flow in-line with productivity. Pellenc Group also introduced IoT-integrated smart crushers that enable winemakers to remotely monitor crushing parameters for data-driven adjustments in real time.

Included in the portfolio are the innovative fully automatic crushers by Zambelli Enotech, featuring adjustable crushing intensity for wineries with the precision and efficiency in focus. It is a great technological evolution that the industry if going through. It is benefiting the quality, storage, and production capacity of wine, and therefore is a critical differentiator between market competitors.

Growing Demand for Environment-Friendly and Energy-Efficient Products

Shift: With sustainability being a cornerstone in the winemaking process, wineries are now looking for grape crushers that are energy-efficient and environmentally friendly that can make a big reduction in their carbon footprint as well as help them comply with the environment regulations.

The growing preference for low-energy crushers with water and waste consumption and recyclable components, are transforming the crushers market. Eco-friendly practices like solar-powered crushers and energy-efficient motors are growing in popularity, especially in Europe and North America, which are increasingly adopting greener production techniques.

Strategic Response: I n response to the increasing demand, Rauch GmbH provided environmental-friendly grape crushers with energy-optimized motors that allowed up to 20 percent less electricity consumption with highly efficient operation.

Amos Industrie launches a series of water-saving crushes that consume 30% less water the solution for eco-friendly wineries Enoitalia developed solar-powered crushers, allowing small and medium sized wineries a way to reduce their energy dependence without sacrificing efficiency. They’re among a growing set of brands that are adopting sustainability-driven innovation to attract the increasingly green-hearted segment of the consumer marketplace.

Demand for Multi-Function Crushers on An Upswing

Shift: Evolution of grape crusher market towards multi-function machines which can crush, de-stem and sort in one unit. This integration allows wineries to bring their processing operations together to get more out of their equipment investments, while producing more at the same time.

These small, cost-effective units are proving increasingly helpful to very large and medium-sized wineries, who have very little horizontal real estate and desire to maximize their little footprint with appropriate machinery. Modular crushers - which can be improved with attachments including, but not limited to, sorting tables and automated conveyors - also continue to gain popularity, in part because of their scalability and flexibility.

Strategic Response: In order to counter this trend, Bucher Vaslin introduced its Delta E series multi-function crushers that integrate crushing, de-stemming and juice separation into a single system, which can provide processing times that are up to 30% speedier. Pellenc Group - Selectiv’ Process 2-in-1 Crusher-Destemmer A much gentler adjustable processing system for various sorts of grapes.

Coincidentally, Zambelli Enotech turned out its modular crusher systems which allow wineries to adjust to changing production demands by adding sorting and de-stemming modules. Such innovations enhance the efficiency and scalability of grape crushers.

The little expert you might have in home and local winemaking?

Shift: A burgeoning interest in home winemaking and small-scale wineries is increasing demand for small, affordable, and simple-to-use grape crushes. Hobbyist winemakers and boutique producers are seeking manual and electric crushers that offer reliability, ease of use and affordability. The hobby of home winemaking is gaining traction, particularly in regions such as North America, Australia and parts of Europe.

Strategic Response: In response to this trend, Marchisio created a line of manual grape crushers for at-home winemakers that were affordable and ease to use. Although Grifo Marchetti is one of the oldest crush manufacturers, they also make one of the smallest eco-friendly ones, with their stainless steel rollers, that are ideal for boutique wineries or hobbyists that want a little more efficiency without breaking the bank.

For those low-example buyers, Enoitalia makes entry-level crushers with adjustable crushing rollers for light use. To fill the gap, these firms are addressing the growing class of home winemakers, creating smaller, accessible-cousin crushers for less unreasonable price points.

Crushing equipment range for the mining industry.

Shift: Winemakers are now asking for customized grape crushers that allow for fine-tuning of crushing intensity, seed breakage and juice extraction. As such, adjustable rollers, variable speeds, and pressure settings have provided evidence for the need for variable in the number of crushers, and this demand is particularly robust in the premium and high-end wine producers focused on quality and consistency. Precision crushing preserves grape integrity, reduces bitter compounds that come from broken seeds and enhances wine quality.

Strategic Response: To meet this demand, Pellenc Group developed fully adjustable grape crushers, with variable spacing between the rollers and speed controls, enabling winemakers to tailor the crushing to the respective grape variety and ripeness. Bucher Vaslin talked about its adjustable pressure crushers, which can enable more gentle crushes of sensitive grape varieties and help avoid contamination of aromas and flavors.

Zambelli Enotech manufactures crushers that can be programmed, allowing winemakers to specify how much, or how little, they crush grapes so that every batch is consistent. These technologies also allow wineries to tighten the reins of their control over wine quality more than ever before.

Emerging Wine-Producing Regions Continue to Grow

Shift: As new wine regions are emerging in Asia, South America and Eastern Europe the demand for effective and cheap grape crushers is increasing. Demand in the forecast period will also benefit grape crusher manufacturers, as countries like China, India, Brazil and Bulgaria have witnessed a boom in investment in winemaking. Wineries in these regions depend a lot on semi-processing, time-efficient and budget-friendly equipment to ensure efficiency during production and fermentation control.

Strategic Response: As this growth continued, Bucher Vaslin and Rauch GmbH turned their attention to Africa and South America in terms of their distribution networks, offering mid-range and entry-level crushers developed specifically for these new wineries.

Recognising this gap in the oenological requirements of Eastern Europe, Pellenc Group further investigated distribution collaborations within the region, concentrating on compressor power in the 12-50 kW class compact, cost-effective types of crusher for small and medium-sized wineries. Amos Industrie had marketed very inexpensive multi-function crushers targeted to the emerging wine producing market and they had the advantage of being scalable to expand with the needs of production.

Focus on After-Sales Service and Maintenance Support

Shift: The increasing investment by wineries in high-tech grape crushers has been a boon for many suppliers, but has also increased the importance of reliable after-sales service and maintenance support. As a consequence, wineries seek manufacturers that offer integrated service packages from on-site service to remote diagnostics and spare parts availability. Xtractd completed the transition simply because of a need to reduce downtime, and maintain consistent performance throughout the harvest.

Strategic Response: In response, Pellenc Group introduced remote monitoring services to allow wineries to receive real-time equipment diagnostics and proactive maintenance. Bucher Vaslin has long maintenance contracts which include priority servicing and available spare parts because they know to minimize downtime during peak seasons.

Rauch GmbH offered 24/7 customers support080 and on-site servicing option instilled in two of its plants augmenting customer satisfaction. Firms are extending their after-sales support to cultivate decades-long customer ties.

Using E-Commerce and Web Sales Platforms

Shift: Growing trend towards the e-commerce and more specifically DTC (Direct-to-consumer) sales channels in the grape crusher market, especially for the Small and Mid-sized crushers. Whether it’s price competition for home winemaking gear or customer review sites, wine makers are buying crushers on the Internet from care providers who respect the ways to provide the service.

Strategic Response: Enoitalia and Grifo Marchetti launched online stores peddling their range of crushers to consumers. Online sales systems increased for Bucher Vaslin and Pellenc Group, enabling in-depth specifications, pricing and online demonstrations. Now these firms are adapting their e-commerce playbooks to enhance access and, in some cases, sales.

The following table shows the estimated growth rates of the top five territories. These are set to exhibit high consumption through 2035.

| Countries | CAGR, 2025 to 2035 |

|---|---|

| USA | 4.3% |

| Germany | 3.8% |

| China | 6.1% |

| Japan | 4.5% |

| India | 6.7% |

Technological innovation in Grape Crushers, growing sustainability, and increasing premium wine production are expected to drive the Grape Crusher Market in the USA Automation and Smart Crushers The rise in the adoption of AI-based crushers that monitor data in real-time for accuracy and performance.

Trend 3: Wineries are investing in energy-efficiency crushers to decrease their carbon footprint. Organic Wine Trends Growing preference for organic and artisanal wines is propelling the demand for precision crushers. FDA Compliance: Ensure food safety standards to create trust among producers and consumers.

The Chinese grape crusher market is booming due to a number of reasons.Vineyards Regions like Ningxia, Xinjiang, and Shandong are growing grapes; an avid demand for industrial crushers Increasing Bootstrap Tourism: The increase of wine tasting and vineyard tours increases the demand for modern crushing systems. Technological Integration: The Arrival of AI-Powered Crushers POLICY SUPPORT Agricultural modernization policies promote the demand of high-end crushing equipment.

Key Trends: Demand of multi-function crushers which can perform both crushing and destemming operation simultaneously. Increasing investment in automated cleaning systems for low-maintenance crushers.

By technology, the Grape Crusher Market in Japan is further divided into automated and non-automated market. High-grain Market for Individual Genders Demand for high-precision crushers is on the rise due to the growing inclination towards boutique and niche wines, especially among wealthy and young consumers.

Automation and Efficiency: Robotic and AI-driven wine crushers are streamlining processes, cutting down on long-term labor costs, and maximizing the consistency of output quality. Clean-Label Production The demand for minimally processed, additive-free wines is driving the need for gentle crushing systems that preserve grape integrity and limit oxidation, adding freshness and purity to the wine. Major Trend Increasing use of low-vibration crushers to reduce damage and enhance quality of juice extraction

| Segment | Value Share (2025) |

|---|---|

| Stainless Steel (By Material) | 67.8% |

World Grapes Crusher Market Analysis By Product Type As designs of grape crushers evolve and users have a need for convenience and durability, stainless steel segment will hold a value share of 67.8% by 2015 in global market for grape crushers. Durable Stainless Steel has excellent resistance to corrosion, staining and wear, making it ideal for wineries.

Performance & Hygiene: It has non-reactive surface that does not effect flavor while crushing and keep the wine elegant. And they are easier to clean and sterilize as they have to adhere to strict food safety regulations.

Technology made progress: The vast majority of present-day grape crushers made of stainless steel nowadays are usually automatic, both avidly absorbing these grapes and extending their processing time, and as a result, we obtain a more homogeneous consistency.

Sustainability & Investment: The sustainability issue has also raised a demand for environment-friendly and low-maintenance equipment such as stainless steel crushers because of the recyclability, and low maintenance cost associated with it.

| Segment | Value Share (2025) |

|---|---|

| Large Industry (By Application) | 45.6% |

On The Back Of Growing Demand From Large-Scale Wineries However, during the forecast period, the largest value share (45.6%) of the Grape Crusher Market will be held by Large Industry segment, 2019 to 2025. High-Volume Production The global wine market continues to expand, and this has led to larger-scale wineries and commercial wine producers dependent on high-capacity grape crushers.

Operational Efficiency: Automated and high-speed crushers reduce human effort, improve efficiency, and provide uniformity in crushing quality. Technological innovations high-tech grape-crushers, which provide precise operation, allow to increase juice yield and reduce waste.

Scalability and Consistency: In large-scale operations, crushing systems are designed for scalability and uniformity, which helps maintain consistency in wine quality even across extensive vintages. Market Growth The global wine industry is growing, and large-scale wineries are expanding production capacity, which creates demand for industrial crusher equipment.

The technological advancements, product innovation and strategic partnerships. By providing various models of efficient, automated grape crushers suited for small, medium, and large wineries, these companies have firmly established themselves. Precision-controlled crushing machines help winemakers maximize juice output while maintaining the integrity of the grapes.Additionally, manufacturers are consistently releasing new designs and features that increase efficiency, lessen manual labor, and make systems easier to operate.

This modern grape processing is set by these companies through innovative integration of smart technology and automation. Their market presence was further strengthened through strategic partnerships with winemakers, vineyard owners, and distributors, which has allowed for wider adoption of the product.

For instance

By material, the market includes wood and stainless steel crushers

It is divided into small industry, medium industry, and large industry.

By distribution channel, grape crushers are sold through multi-specialty suppliers, wholesalers, manufacturers, and online platforms

The market is analyzed across North America, Latin America, Western Europe, Eastern Europe, Balkans & Baltic, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Table 1: Global Market Value (US$ Million) Forecast by Region, 2018 to 2033

Table 2: Global Market Volume (MT) Forecast by Region, 2018 to 2033

Table 3: Global Market Value (US$ Million) Forecast by Material Type, 2018 to 2033

Table 4: Global Market Volume (MT) Forecast by Material Type, 2018 to 2033

Table 5: Global Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 6: Global Market Volume (MT) Forecast by Application, 2018 to 2033

Table 7: Global Market Value (US$ Million) Forecast by Distribution channel, 2018 to 2033

Table 8: Global Market Volume (MT) Forecast by Distribution channel, 2018 to 2033

Table 9: North America Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 10: North America Market Volume (MT) Forecast by Country, 2018 to 2033

Table 11: North America Market Value (US$ Million) Forecast by Material Type, 2018 to 2033

Table 12: North America Market Volume (MT) Forecast by Material Type, 2018 to 2033

Table 13: North America Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 14: North America Market Volume (MT) Forecast by Application, 2018 to 2033

Table 15: North America Market Value (US$ Million) Forecast by Distribution channel, 2018 to 2033

Table 16: North America Market Volume (MT) Forecast by Distribution channel, 2018 to 2033

Table 17: Latin America Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 18: Latin America Market Volume (MT) Forecast by Country, 2018 to 2033

Table 19: Latin America Market Value (US$ Million) Forecast by Material Type, 2018 to 2033

Table 20: Latin America Market Volume (MT) Forecast by Material Type, 2018 to 2033

Table 21: Latin America Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 22: Latin America Market Volume (MT) Forecast by Application, 2018 to 2033

Table 23: Latin America Market Value (US$ Million) Forecast by Distribution channel, 2018 to 2033

Table 24: Latin America Market Volume (MT) Forecast by Distribution channel, 2018 to 2033

Table 25: Europe Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 26: Europe Market Volume (MT) Forecast by Country, 2018 to 2033

Table 27: Europe Market Value (US$ Million) Forecast by Material Type, 2018 to 2033

Table 28: Europe Market Volume (MT) Forecast by Material Type, 2018 to 2033

Table 29: Europe Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 30: Europe Market Volume (MT) Forecast by Application, 2018 to 2033

Table 31: Europe Market Value (US$ Million) Forecast by Distribution channel, 2018 to 2033

Table 32: Europe Market Volume (MT) Forecast by Distribution channel, 2018 to 2033

Table 33: East Asia Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 34: East Asia Market Volume (MT) Forecast by Country, 2018 to 2033

Table 35: East Asia Market Value (US$ Million) Forecast by Material Type, 2018 to 2033

Table 36: East Asia Market Volume (MT) Forecast by Material Type, 2018 to 2033

Table 37: East Asia Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 38: East Asia Market Volume (MT) Forecast by Application, 2018 to 2033

Table 39: East Asia Market Value (US$ Million) Forecast by Distribution channel, 2018 to 2033

Table 40: East Asia Market Volume (MT) Forecast by Distribution channel, 2018 to 2033

Table 41: South Asia Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 42: South Asia Market Volume (MT) Forecast by Country, 2018 to 2033

Table 43: South Asia Market Value (US$ Million) Forecast by Material Type, 2018 to 2033

Table 44: South Asia Market Volume (MT) Forecast by Material Type, 2018 to 2033

Table 45: South Asia Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 46: South Asia Market Volume (MT) Forecast by Application, 2018 to 2033

Table 47: South Asia Market Value (US$ Million) Forecast by Distribution channel, 2018 to 2033

Table 48: South Asia Market Volume (MT) Forecast by Distribution channel, 2018 to 2033

Table 49: Oceania Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 50: Oceania Market Volume (MT) Forecast by Country, 2018 to 2033

Table 51: Oceania Market Value (US$ Million) Forecast by Material Type, 2018 to 2033

Table 52: Oceania Market Volume (MT) Forecast by Material Type, 2018 to 2033

Table 53: Oceania Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 54: Oceania Market Volume (MT) Forecast by Application, 2018 to 2033

Table 55: Oceania Market Value (US$ Million) Forecast by Distribution channel, 2018 to 2033

Table 56: Oceania Market Volume (MT) Forecast by Distribution channel, 2018 to 2033

Table 57: MEA Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 58: MEA Market Volume (MT) Forecast by Country, 2018 to 2033

Table 59: MEA Market Value (US$ Million) Forecast by Material Type, 2018 to 2033

Table 60: MEA Market Volume (MT) Forecast by Material Type, 2018 to 2033

Table 61: MEA Market Value (US$ Million) Forecast by Application, 2018 to 2033

Table 62: MEA Market Volume (MT) Forecast by Application, 2018 to 2033

Table 63: MEA Market Value (US$ Million) Forecast by Distribution channel, 2018 to 2033

Table 64: MEA Market Volume (MT) Forecast by Distribution channel, 2018 to 2033

Figure 1: Global Market Value (US$ Million) by Material Type, 2023 to 2033

Figure 2: Global Market Value (US$ Million) by Application, 2023 to 2033

Figure 3: Global Market Value (US$ Million) by Distribution channel, 2023 to 2033

Figure 4: Global Market Value (US$ Million) by Region, 2023 to 2033

Figure 5: Global Market Value (US$ Million) Analysis by Region, 2018 to 2033

Figure 6: Global Market Volume (MT) Analysis by Region, 2018 to 2033

Figure 7: Global Market Value Share (%) and BPS Analysis by Region, 2023 to 2033

Figure 8: Global Market Y-o-Y Growth (%) Projections by Region, 2023 to 2033

Figure 9: Global Market Value (US$ Million) Analysis by Material Type, 2018 to 2033

Figure 10: Global Market Volume (MT) Analysis by Material Type, 2018 to 2033

Figure 11: Global Market Value Share (%) and BPS Analysis by Material Type, 2023 to 2033

Figure 12: Global Market Y-o-Y Growth (%) Projections by Material Type, 2023 to 2033

Figure 13: Global Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 14: Global Market Volume (MT) Analysis by Application, 2018 to 2033

Figure 15: Global Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 16: Global Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 17: Global Market Value (US$ Million) Analysis by Distribution channel, 2018 to 2033

Figure 18: Global Market Volume (MT) Analysis by Distribution channel, 2018 to 2033

Figure 19: Global Market Value Share (%) and BPS Analysis by Distribution channel, 2023 to 2033

Figure 20: Global Market Y-o-Y Growth (%) Projections by Distribution channel, 2023 to 2033

Figure 21: Global Market Attractiveness by Material Type, 2023 to 2033

Figure 22: Global Market Attractiveness by Application, 2023 to 2033

Figure 23: Global Market Attractiveness by Distribution channel, 2023 to 2033

Figure 24: Global Market Attractiveness by Region, 2023 to 2033

Figure 25: North America Market Value (US$ Million) by Material Type, 2023 to 2033

Figure 26: North America Market Value (US$ Million) by Application, 2023 to 2033

Figure 27: North America Market Value (US$ Million) by Distribution channel, 2023 to 2033

Figure 28: North America Market Value (US$ Million) by Country, 2023 to 2033

Figure 29: North America Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 30: North America Market Volume (MT) Analysis by Country, 2018 to 2033

Figure 31: North America Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 32: North America Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 33: North America Market Value (US$ Million) Analysis by Material Type, 2018 to 2033

Figure 34: North America Market Volume (MT) Analysis by Material Type, 2018 to 2033

Figure 35: North America Market Value Share (%) and BPS Analysis by Material Type, 2023 to 2033

Figure 36: North America Market Y-o-Y Growth (%) Projections by Material Type, 2023 to 2033

Figure 37: North America Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 38: North America Market Volume (MT) Analysis by Application, 2018 to 2033

Figure 39: North America Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 40: North America Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 41: North America Market Value (US$ Million) Analysis by Distribution channel, 2018 to 2033

Figure 42: North America Market Volume (MT) Analysis by Distribution channel, 2018 to 2033

Figure 43: North America Market Value Share (%) and BPS Analysis by Distribution channel, 2023 to 2033

Figure 44: North America Market Y-o-Y Growth (%) Projections by Distribution channel, 2023 to 2033

Figure 45: North America Market Attractiveness by Material Type, 2023 to 2033

Figure 46: North America Market Attractiveness by Application, 2023 to 2033

Figure 47: North America Market Attractiveness by Distribution channel, 2023 to 2033

Figure 48: North America Market Attractiveness by Country, 2023 to 2033

Figure 49: Latin America Market Value (US$ Million) by Material Type, 2023 to 2033

Figure 50: Latin America Market Value (US$ Million) by Application, 2023 to 2033

Figure 51: Latin America Market Value (US$ Million) by Distribution channel, 2023 to 2033

Figure 52: Latin America Market Value (US$ Million) by Country, 2023 to 2033

Figure 53: Latin America Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 54: Latin America Market Volume (MT) Analysis by Country, 2018 to 2033

Figure 55: Latin America Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 56: Latin America Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 57: Latin America Market Value (US$ Million) Analysis by Material Type, 2018 to 2033

Figure 58: Latin America Market Volume (MT) Analysis by Material Type, 2018 to 2033

Figure 59: Latin America Market Value Share (%) and BPS Analysis by Material Type, 2023 to 2033

Figure 60: Latin America Market Y-o-Y Growth (%) Projections by Material Type, 2023 to 2033

Figure 61: Latin America Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 62: Latin America Market Volume (MT) Analysis by Application, 2018 to 2033

Figure 63: Latin America Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 64: Latin America Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 65: Latin America Market Value (US$ Million) Analysis by Distribution channel, 2018 to 2033

Figure 66: Latin America Market Volume (MT) Analysis by Distribution channel, 2018 to 2033

Figure 67: Latin America Market Value Share (%) and BPS Analysis by Distribution channel, 2023 to 2033

Figure 68: Latin America Market Y-o-Y Growth (%) Projections by Distribution channel, 2023 to 2033

Figure 69: Latin America Market Attractiveness by Material Type, 2023 to 2033

Figure 70: Latin America Market Attractiveness by Application, 2023 to 2033

Figure 71: Latin America Market Attractiveness by Distribution channel, 2023 to 2033

Figure 72: Latin America Market Attractiveness by Country, 2023 to 2033

Figure 73: Europe Market Value (US$ Million) by Material Type, 2023 to 2033

Figure 74: Europe Market Value (US$ Million) by Application, 2023 to 2033

Figure 75: Europe Market Value (US$ Million) by Distribution channel, 2023 to 2033

Figure 76: Europe Market Value (US$ Million) by Country, 2023 to 2033

Figure 77: Europe Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 78: Europe Market Volume (MT) Analysis by Country, 2018 to 2033

Figure 79: Europe Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 80: Europe Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 81: Europe Market Value (US$ Million) Analysis by Material Type, 2018 to 2033

Figure 82: Europe Market Volume (MT) Analysis by Material Type, 2018 to 2033

Figure 83: Europe Market Value Share (%) and BPS Analysis by Material Type, 2023 to 2033

Figure 84: Europe Market Y-o-Y Growth (%) Projections by Material Type, 2023 to 2033

Figure 85: Europe Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 86: Europe Market Volume (MT) Analysis by Application, 2018 to 2033

Figure 87: Europe Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 88: Europe Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 89: Europe Market Value (US$ Million) Analysis by Distribution channel, 2018 to 2033

Figure 90: Europe Market Volume (MT) Analysis by Distribution channel, 2018 to 2033

Figure 91: Europe Market Value Share (%) and BPS Analysis by Distribution channel, 2023 to 2033

Figure 92: Europe Market Y-o-Y Growth (%) Projections by Distribution channel, 2023 to 2033

Figure 93: Europe Market Attractiveness by Material Type, 2023 to 2033

Figure 94: Europe Market Attractiveness by Application, 2023 to 2033

Figure 95: Europe Market Attractiveness by Distribution channel, 2023 to 2033

Figure 96: Europe Market Attractiveness by Country, 2023 to 2033

Figure 97: East Asia Market Value (US$ Million) by Material Type, 2023 to 2033

Figure 98: East Asia Market Value (US$ Million) by Application, 2023 to 2033

Figure 99: East Asia Market Value (US$ Million) by Distribution channel, 2023 to 2033

Figure 100: East Asia Market Value (US$ Million) by Country, 2023 to 2033

Figure 101: East Asia Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 102: East Asia Market Volume (MT) Analysis by Country, 2018 to 2033

Figure 103: East Asia Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 104: East Asia Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 105: East Asia Market Value (US$ Million) Analysis by Material Type, 2018 to 2033

Figure 106: East Asia Market Volume (MT) Analysis by Material Type, 2018 to 2033

Figure 107: East Asia Market Value Share (%) and BPS Analysis by Material Type, 2023 to 2033

Figure 108: East Asia Market Y-o-Y Growth (%) Projections by Material Type, 2023 to 2033

Figure 109: East Asia Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 110: East Asia Market Volume (MT) Analysis by Application, 2018 to 2033

Figure 111: East Asia Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 112: East Asia Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 113: East Asia Market Value (US$ Million) Analysis by Distribution channel, 2018 to 2033

Figure 114: East Asia Market Volume (MT) Analysis by Distribution channel, 2018 to 2033

Figure 115: East Asia Market Value Share (%) and BPS Analysis by Distribution channel, 2023 to 2033

Figure 116: East Asia Market Y-o-Y Growth (%) Projections by Distribution channel, 2023 to 2033

Figure 117: East Asia Market Attractiveness by Material Type, 2023 to 2033

Figure 118: East Asia Market Attractiveness by Application, 2023 to 2033

Figure 119: East Asia Market Attractiveness by Distribution channel, 2023 to 2033

Figure 120: East Asia Market Attractiveness by Country, 2023 to 2033

Figure 121: South Asia Market Value (US$ Million) by Material Type, 2023 to 2033

Figure 122: South Asia Market Value (US$ Million) by Application, 2023 to 2033

Figure 123: South Asia Market Value (US$ Million) by Distribution channel, 2023 to 2033

Figure 124: South Asia Market Value (US$ Million) by Country, 2023 to 2033

Figure 125: South Asia Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 126: South Asia Market Volume (MT) Analysis by Country, 2018 to 2033

Figure 127: South Asia Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 128: South Asia Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 129: South Asia Market Value (US$ Million) Analysis by Material Type, 2018 to 2033

Figure 130: South Asia Market Volume (MT) Analysis by Material Type, 2018 to 2033

Figure 131: South Asia Market Value Share (%) and BPS Analysis by Material Type, 2023 to 2033

Figure 132: South Asia Market Y-o-Y Growth (%) Projections by Material Type, 2023 to 2033

Figure 133: South Asia Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 134: South Asia Market Volume (MT) Analysis by Application, 2018 to 2033

Figure 135: South Asia Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 136: South Asia Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 137: South Asia Market Value (US$ Million) Analysis by Distribution channel, 2018 to 2033

Figure 138: South Asia Market Volume (MT) Analysis by Distribution channel, 2018 to 2033

Figure 139: South Asia Market Value Share (%) and BPS Analysis by Distribution channel, 2023 to 2033

Figure 140: South Asia Market Y-o-Y Growth (%) Projections by Distribution channel, 2023 to 2033

Figure 141: South Asia Market Attractiveness by Material Type, 2023 to 2033

Figure 142: South Asia Market Attractiveness by Application, 2023 to 2033

Figure 143: South Asia Market Attractiveness by Distribution channel, 2023 to 2033

Figure 144: South Asia Market Attractiveness by Country, 2023 to 2033

Figure 145: Oceania Market Value (US$ Million) by Material Type, 2023 to 2033

Figure 146: Oceania Market Value (US$ Million) by Application, 2023 to 2033

Figure 147: Oceania Market Value (US$ Million) by Distribution channel, 2023 to 2033

Figure 148: Oceania Market Value (US$ Million) by Country, 2023 to 2033

Figure 149: Oceania Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 150: Oceania Market Volume (MT) Analysis by Country, 2018 to 2033

Figure 151: Oceania Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 152: Oceania Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 153: Oceania Market Value (US$ Million) Analysis by Material Type, 2018 to 2033

Figure 154: Oceania Market Volume (MT) Analysis by Material Type, 2018 to 2033

Figure 155: Oceania Market Value Share (%) and BPS Analysis by Material Type, 2023 to 2033

Figure 156: Oceania Market Y-o-Y Growth (%) Projections by Material Type, 2023 to 2033

Figure 157: Oceania Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 158: Oceania Market Volume (MT) Analysis by Application, 2018 to 2033

Figure 159: Oceania Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 160: Oceania Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 161: Oceania Market Value (US$ Million) Analysis by Distribution channel, 2018 to 2033

Figure 162: Oceania Market Volume (MT) Analysis by Distribution channel, 2018 to 2033

Figure 163: Oceania Market Value Share (%) and BPS Analysis by Distribution channel, 2023 to 2033

Figure 164: Oceania Market Y-o-Y Growth (%) Projections by Distribution channel, 2023 to 2033

Figure 165: Oceania Market Attractiveness by Material Type, 2023 to 2033

Figure 166: Oceania Market Attractiveness by Application, 2023 to 2033

Figure 167: Oceania Market Attractiveness by Distribution channel, 2023 to 2033

Figure 168: Oceania Market Attractiveness by Country, 2023 to 2033

Figure 169: MEA Market Value (US$ Million) by Material Type, 2023 to 2033

Figure 170: MEA Market Value (US$ Million) by Application, 2023 to 2033

Figure 171: MEA Market Value (US$ Million) by Distribution channel, 2023 to 2033

Figure 172: MEA Market Value (US$ Million) by Country, 2023 to 2033

Figure 173: MEA Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 174: MEA Market Volume (MT) Analysis by Country, 2018 to 2033

Figure 175: MEA Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 176: MEA Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 177: MEA Market Value (US$ Million) Analysis by Material Type, 2018 to 2033

Figure 178: MEA Market Volume (MT) Analysis by Material Type, 2018 to 2033

Figure 179: MEA Market Value Share (%) and BPS Analysis by Material Type, 2023 to 2033

Figure 180: MEA Market Y-o-Y Growth (%) Projections by Material Type, 2023 to 2033

Figure 181: MEA Market Value (US$ Million) Analysis by Application, 2018 to 2033

Figure 182: MEA Market Volume (MT) Analysis by Application, 2018 to 2033

Figure 183: MEA Market Value Share (%) and BPS Analysis by Application, 2023 to 2033

Figure 184: MEA Market Y-o-Y Growth (%) Projections by Application, 2023 to 2033

Figure 185: MEA Market Value (US$ Million) Analysis by Distribution channel, 2018 to 2033

Figure 186: MEA Market Volume (MT) Analysis by Distribution channel, 2018 to 2033

Figure 187: MEA Market Value Share (%) and BPS Analysis by Distribution channel, 2023 to 2033

Figure 188: MEA Market Y-o-Y Growth (%) Projections by Distribution channel, 2023 to 2033

Figure 189: MEA Market Attractiveness by Material Type, 2023 to 2033

Figure 190: MEA Market Attractiveness by Application, 2023 to 2033

Figure 191: MEA Market Attractiveness by Distribution channel, 2023 to 2033

Figure 192: MEA Market Attractiveness by Country, 2023 to 2033

The global industry is estimated at a value of USD 496.5 million in 2025.

Some of the leaders in this industry include Enoveneta, VLS technology, Della Toffols Group Mori Tem.

The North America is projected to hold a revenue share of 40% over the forecast period.

The industry is projected to grow at a forecast CAGR of 5.0% from 2025 to 2035.

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.