The market for Germany protein A resins is looking forward to grow from USD 40.5 million in 2025 up to USD 44.7 million by 2035, at a CAGR of 1.0%.

Market Overview

| Attributes | Values |

|---|---|

| Estimated Germany Market Size 2025 | USD 40.5 million |

| Projected Germany Value 2035 | USD 44.7 million |

| Value-based CAGR 2025 to 2035 | 1.0% |

The Germany protein A resins market is expanding due to increasing demand for highly selective purification resins across the biopharmaceutical industry. Further, next-generation protein A resins and advancements in chromatography techniques are helping even more in the development of better efficiency for purifying antibodies. The growing importance of personalized medicine and monoclonal antibodies produced for cancer and autoimmune diseases are also increasing demand. Bio separation technologies such as multi-cycle and high capacity resins are improving process scalability and reducing production costs. Further regulatory support for biopharmaceutical advancements and the expansion of manufacturing facilities is driving further adoption of protein A resin across multiple applications.

Explore FMI!

Book a free demo

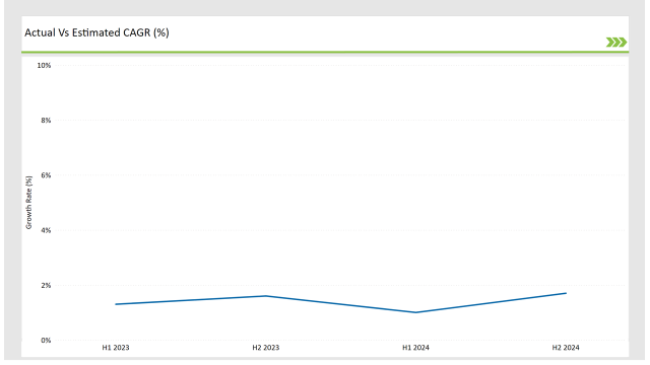

This table shows key changes in the compounded annual growth rate over intervals of six months for the base year in 2024 and the current year of 2025, giving an idea of revenue realization trend of the company.

| Year | 2024 |

|---|---|

| H1 Growth Rate (%) | 1.3 |

| H2 Growth Rate (%) | 1.6 |

| Year | 2025 |

|---|---|

| H1 Growth Rate (%) | 1.0 |

| H2 Growth Rate (%) | 1.7 |

The market has demonstrated steady growth, with an decline of 31 basis points in H1 2025 compared to H1 2024. H2 2025 is projected to grow by 12 basis points, driven by increasing adoption of recombinant protein A resins and innovations in bioseparation technologies. Rising investments in next-generation chromatography systems and automation in downstream processing are further fuelling market expansion. The integration of AI-driven analytics for resin performance optimization is also enhancing process efficiency.

Additionally, growing collaborations between biotech firms and academic institutions are leading to advancement in protein purification methodologies further accelerating the market outlook for protein A resin.

| Date | Development/M&A Activity & Details |

|---|---|

| Sep-25 | Investment: Tosoh Biosciences is mainly contributing in Investment in advanced agarose-based matrix technology for improved antibody purification. |

| Jul-24 | Collaboration: Cytiva is focusing on growth in strategic partnerships between resin manufacturers and biotech firms. |

| Mar-24 | Product Approval: BfArM approves new bio separation technology integrating protein A resins for the Pfizer. |

Biotechnology Advancements in Protein A Resin Development

The integration of advanced biotechnological methods, such as engineered ligands and genetic modifications, is revolutionizing the protein A resins market. Companies, for example, Sartorius AG and Lonza Group, are at the forefront of inventing highly efficient resins that are stable and have better binding capacity. Funding by the government on innovation in biopharmaceuticals is further aiding efforts toward R&D, making the resins have longer lifespans, also very cost-efficient.

Increasing Investment in Sustainable Manufacturing of Resin

Sustainability is becoming an important focus area for protein A resin manufacturers. The giant resin manufacturers are adopting green manufacturing, including minimizing use of solvents and streamlining processes for waste efficiency in resin production. This trend is aligned with regulatory initiatives in Germany promoting green bioprocessing and ensuring environmentally responsible production of chromatography resins.

Automation and AI Integration in Bioprocessing

The AI analytics are bettering the monitoring of resin performance improving yield and quality control. The involvement of automation in chromatography is also lessened, hence improving precision and efficiency in the manufacture of biopharmaceuticals.

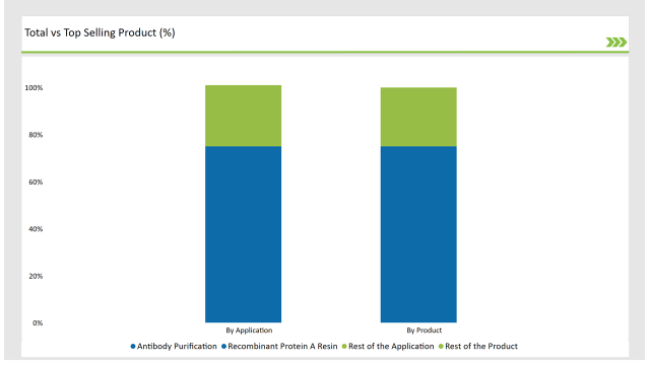

Natural protein A resins continue to be widely used for their high specificity in antibody purification. However, recombinant protein A resins are gaining traction due to their improved binding capacity and stability. By 2035, recombinant resins are expected to capture over 55% of the market share, driven by advancements in engineered ligands and enhanced resin durability.

Agarose-based matrices remain the most commonly used platform for protein A resins due to their superior binding efficiency and scalability. Glass or silica-based matrices are witnessing moderate growth, while organic polymer-based matrices are emerging as alternatives for enhanced purification efficiency and cost-effectiveness.

Antibody purification is the major application segment occupying more than 70% market share of the protein A resins market. High-performance resins are demanded more and more due to increased monoclonal antibody-based drugs and the innovation of new techniques. Immunoprecipitation techniques are rising especially in applications for research use. In precision medicine, such highly selective methods of purification also become necessary.

Several biopharmaceutical producers remain the primary end users of protein A resins with extensive applications in antibody production and downstream processing. Clinical research laboratories are increasingly adopting these resins for experimental and preclinical studies while academic institutes contribute to innovation through novel resin development and application research.

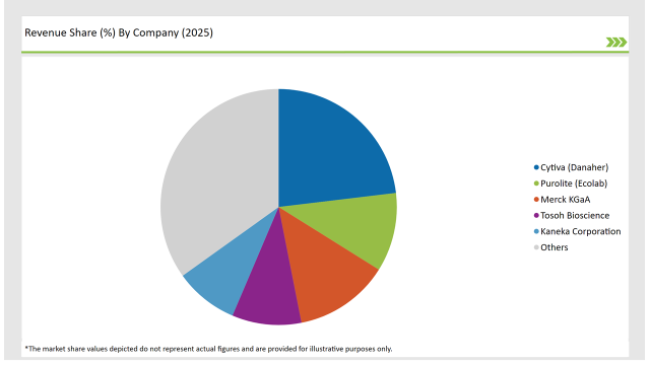

The market for protein A resins in Germany is moderately strengthen with key players including Merck KGaA, Bayer AG, Sartorius AG and Thermo Fisher Scientific. These companies are investing in increasing resin production capacity, high-performance resins, and forming strategic partnerships to strengthen market positions.

Even smaller biotechnology companies and academic research institutions are now entering the market, focused on developing cheaper resin alternatives and improving bioseparation techniques.

The recent Government and Private Investments in Bioprocessing Infrastructure is expected to support market expansion and innovation in protein purification solutions.

By 2025 to 2035 , the Germany Protein A resin market is expected to grow at a CAGR of 1%.

By 2035, the sales value of the Germany protein A resin industry is expected to reach is 44.7 million.

Key factors propelling the Germany protein A resin market include rising focus on cost efficiency,biosimilar development, investment in bioprocessing facilities, and personalized medicine demand.

The top 5 players operating in the global protein A resin market include Cytiva (Danaher), Purolite (Ecolab), Merck KGaA, Tosoh Bioscience and Kaneka Corporation.

Epidemic Keratoconjunctivitis Treatment Market Overview – Growth, Trends & Forecast 2025 to 2035

Eosinophilia Therapeutics Market Insights – Trends & Forecast 2025 to 2035

Endometrial Ablation Market Analysis - Size, Share & Forecast 2025 to 2035

Endotracheal Tube Market - Growth & Demand Outlook 2025 to 2035

Encephalitis Treatment Market - Growth & Future Trends 2025 to 2035

Edward’s Syndrome Treatment Market – Growth & Future Prospects 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.