The Germany pharmaceutical intermediate market is expected to reach USD 1,729.8 million in 2025 and is projected to reach a total value of USD 2,394.7 million by 2035. This represents a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2025 to 2035.

| Attributes | Values |

|---|---|

| Estimated Germany Industry Size (2025) | USD 1,729.8 million |

| Projected Global Value (2035) | USD 2,394.7 million |

| Value-based CAGR (2025 to 2035) | 3.3% |

Germany pharmaceutical intermediates market is likely to grow sizably. The pharmaceutical industry has the strong, dynamic manufacturing capacity and cutting-edge research, currently best in class. Several large multinationals, biotechnology, and contract pharmaceutical companies operate within this country and are creating new products and capacity through a very large pool of scientists and engineers.

The target market is expected to grab a huge size in the worldwide market. Hence, in the year 2025, this is going to be 1,729.8 million along with an incredibly high CAGR of 3.3% from 2035.

Skilled labor along with good infrastructures in Germany supports the pharmaceutical intermediates of development and scalability. Furthermore, Germany is centrally located within Europe, offering access to key markets and making trade and collaboration easier.

Government support for the life sciences sector in general, with incentives for R&D and manufacturing, adds to the market's growth, ensuring continuous growth in pharmaceutical intermediates.

Explore FMI!

Book a free demo

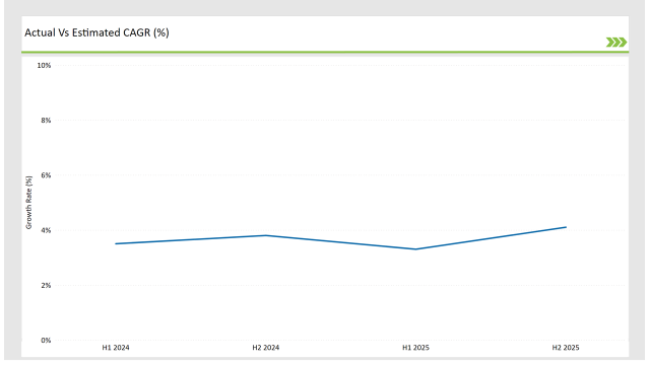

The table below offers a detailed comparative assessment of the changes in the compound annual growth rate (CAGR) over six months for the base year (2024) and the current year (2025) specifically for the Germany pharmaceutical intermediate market.

This bi-annual report highlights all major shifts in the dynamics of market and reveals patterns of revenue realization so that the stakeholders will understand the trajectory of growth much better within the calendar year. The first half of the calendar year is January to June, called H1, and the second half is July to December, H2.

H1 represents time between January and June, H2 Represents time between July and December

Germany is likely to achieve a growth in the pharmaceutical intermediate sector with 3.5% CAGR in the first half of the year 2024, then to rise for an increase at 3.8% for the second half of the year.

Growth Rate in 2024 will show a slight marginal decline to 3.3% in H1 and it will increase by 4.1% in H2. This pattern is down 24 basis points from the first half of 2024 to the first half of 2025, but in the second half of 2025, it increased up by 22 basis points than that of the second half of 2024.

This figure candidly depicts the changing and dynamic nature of the scenario of the German pharmaceutical intermediate market, brought about by regulatory change, consumer preferences, and innovation of complex intermediates. This semi-annual breakdown is critical for businesses planning their strategies to capitalize on the anticipated growth and navigate the complexities of the market.

| Date | Development/M&A Activity & Details |

|---|---|

| 2025 | Strategic Collaboration: Cambrex is emphasizing on making strategic collaborations for expansion of their production capabilities |

| 2024 | Launch: BASF and other Manufacturers are focusing on Launch of Complex Intermediates to the Market |

| 2024 | International Conferences: Pharmaceutical intermediate manufacturers such as Interchem is focusing on participating in international conferences |

Availability of Advanced Infrastructure for Manufacturing Anticipates Growth of Pharmaceutical Intermediate market in the Country

The growth of pharmaceutical intermediates is supported by advanced infrastructure for manufacturing in Germany, enabling large-scale and efficient production.

It assures scalability and high quality standards with state-of-the-art technologies such as automated systems, precision equipment, and high-throughput processes. This will enable the synthesis of complex intermediates rapidly and at low cost to meet growing demand in both domestic and international markets.

Strong quality control measures put in place have ensured that German manufacturers can produce intermediates reliably according to the most exacting regulatory standards. Quick scaling of operations is very conducive to meeting rising demand for the pharmaceutical intermediates created by innovative and market-penetrating activities.

Growing focus of key players on Outsourcing Production Process In Germany

Strategic partnerships can help pharmaceutical firms reduce production costs, enhance efficiency, and improve capacity without heavy investment in infrastructures. Many of the CMOs are specialist manufacturers of intermediates and can ensure continuous supply at reduced costs.

This model allows pharmaceutical firms to concentrate on R&D and marketing while outsourcing complex intermediate manufacturing to specialists. Due to the high demand for new drugs, CMOs will become highly essential in meeting the increased demand for specialty intermediates required in drug manufacture.

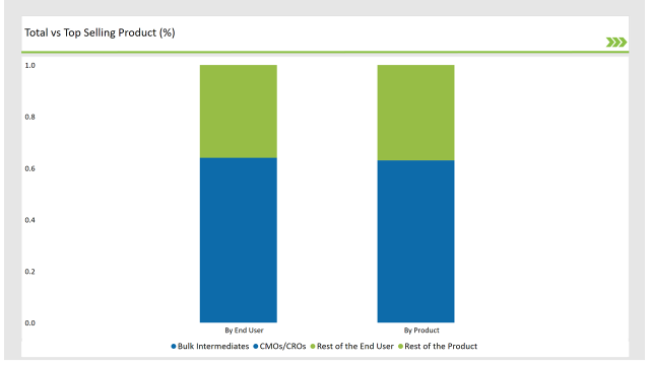

% share of Individual categories by Product Type and End User in 2025

Bulk drug intermediates records significant surge in the market owing to its growing adoption in manufacturing of dietary supplements

The growing trend of cost containment in the healthcare sector could be a prime reason for the dominance of bulk drug intermediates in Germany's pharmaceutical intermediate market. Bulk intermediates provide an economy of scale approach to manufacture active pharmaceutical ingredients in large quantities; this is where controlling the drug price becomes easy, especially generics.

Increasingly, biosimilars demand more of such bulk intermediates, as those drugs are mostly manufactured in mass production. Furthermore, Germany's legal regime has adequately ensured that the quality of bulk intermediates is high, thereby becoming more appealing in domestic markets as well as global markets.

The incorporation of digital and automation technologies into bulk drug intermediates production enhances efficiency and scalability, supporting growth. Partnerships between pharmaceutical companies and CMOs focused on bulk intermediates help advance the reliability and flexibility required by supply chains for meeting global demand.

Emphasis on outsourcing their production facilities has aided CMOs to hold dominant position

In terms of end user, CMOs hold dominant position by holding 64.8% of the Germany pharmaceutical intermediate market. Various reasons make CMOs dominant in the Germany pharmaceutical intermediate market.

Firstly, they are cost-effective as companies just need to outsource their production instead of investing in an expensive facility to manufacture the medicine themselves. This also enables pharmaceutical firms to focus on research and development. CMOs also offer scalability, flexibility, and specialized expertise in complex manufacturing processes.

The number of CMOs addressing large volumes of production accordingly increases with the increasing demand for generic drugs and biologics. In addition, regulatory compliance and quality control make them alluring to pharmaceutical companies in ensuring the safe and efficient production of intermediates while minimizing risk and time to market.

Note: above chart is indicative in nature

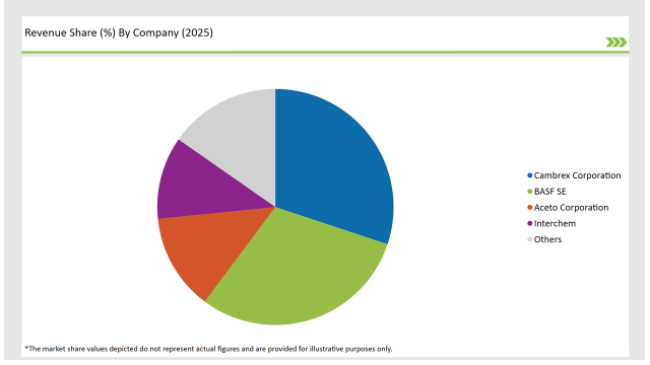

The Germany pharmaceutical intermediate market is moderately fragmented, with a mix of multinational corporations and regional players contributing to a dynamic competitive environment.

Companies like Cambrex Corporation, BASF SE, Aceto Corporation, Interchem, Cambrex Corporation, Arkema Inc. dominate the market by leveraging advanced technologies for streamlining their production process. However, smaller companies are also carving out niches by specializing in unique color solutions and catering to specific consumer needs.

The competitive landscape of the Germany pharmaceutical intermediate market features a blend of major multinational corporations and innovative regional companies.

By 2035, the Germany pharmaceutical intermediate market is expected to grow at a CAGR of 3.3%.

By 2035, the sales value of the Germany pharmaceutical intermediate industry is expected to reach USD 2394.7 million.

Key factors propelling the Germany pharmaceutical intermediate market include the growing strategic collaboration of market players, and increased focus towards development of new intermediate products.

Prominent players in the Germany pharmaceutical intermediate manufacturing include BASF SE, Cambrex Corporation, Interchem, Arkema Inc, Pfizer, BMSetc, Midas Pharma GmbH, Chiracon GmbH, Codexis, Inc, A.R. Life Sciences Private Limited, Dishman Group and Dextra Laboratories Limited.

The industry includes chemical intermediates, bulk drug intermediates and custom intermediates.

Available in forms branded drug intermediates, and generic drug intermediates.

The industry is divided into analgesics, anti-inflammatory drugs, Cardiovascular Drugs, Anti-diabetic Drugs, Antimicrobial Drugs, Anti-cancer Drugs and others.

The industry is classified by end user as biotech and pharma companies, research laboratory and CMOs/CROs

The Prurigo Nodularis (PN) Treatment Market is segmented by product, and end user from 2025 to 2035

Warm Autoimmune Hemolytic Anemia (WAIHA) Treatment Market Analysis by Drug Class, Distribution Channel, and Region through 2035

Atrophic Vaginitis Treatment Market Analysis And Forecast by Diagnosis, Treatment, Therapy Type, Distribution Channel, and Region through 2035

Adrenal Crisis Management Market Analysis and Forecast, By Diagnosis Method, Treatment Method, Distribution Channel, and Region, through 2035

Birch Allergy Treatment Market Analysis by Drug Class, Route of Administration, Distribution Channel and Region: Forecast from 2025 to 2035

Cancer Vaccines Market Analysis by Technology, Treatment Method, Application and Region from 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.