Manufacturers are shifting towards automation, efficiency, and sustainability in packaging processes, thus evolving the landscape of flow wrap machines. One major driving force for innovation in high-speed wrapping technologies, eco-friendly materials, and smart packaging features have been demand from food, pharmaceutical, personal care, and industrial sectors. To further enhance packaging efficiency while minimizing waste, companies have begun to invest heavily in AI-based defect detection, predictive maintenance, and precision sealing technologies.

Manufacturers are optimizing the design of machines to offer compatibility with a wide variety of materials, such as biodegradable films, recyclable plastics, and paper wraps. Therefore, the machinery is moving towards smaller, more energy-efficient, and multi-functional designs that increase throughput and minimize carbon emissions.

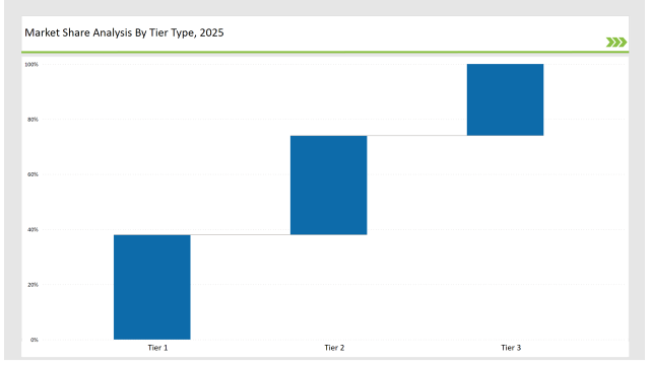

38% of the market is held by Tier 1 players like Bosch Packaging Technology, Syntegon, and ULMA Packaging due to their proficiency in high-performance automation solutions, advanced material handling systems, and global distribution networks.

Tier 2 firms like IMA Group, PFM Packaging, and Coesia Group comprise 36% of the market and offer cost-effective, flexible, and customized flow wrap machines for various applications.

Tier 3 companies comprise several regional and niche players who specialize in high-speed, compact, and specialty wrapping machines and capture 26% of the market. These are companies that emphasize localized production, sustainability in packaging solutions, and advanced sealing technologies.

| Category | Market Share (%) |

|---|---|

| Top 3 (Bosch Packaging Technology, Syntegon, ULMA Packaging) | 18% |

| Rest of Top 5 (IMA Group, PFM Packaging) | 14% |

| Next 5 of Top 10 (Coesia Group, MULTIVAC, FUJI Machinery, Cavanna Packaging, Omori Machinery) | 6% |

The flow wrap machines industry serves multiple sectors where speed, precision, and sustainability are essential. Companies are innovating to enhance packaging reliability, reduce waste, and meet evolving regulatory demands.

The manufacturers are optimizing these flow wrap machines for high-speed wrapping, sustainable material compatibility, and intelligent automation features. They are also equipping sophisticated servo motors to achieve speed and precision during the packing process. Ultra-thin sealing technologies are being developed by companies to reduce consumption while ensuring product integrity.

Automation and sustainability are driving the transformation of the flow wrap machines industry. Companies are integrating AI-powered quality control, robotic product handling, and energy-efficient heating elements to enhance machine performance. Businesses are investing in ultra-thin, high-barrier films to improve packaging sustainability. Manufacturers are developing smart touch interfaces with real-time diagnostics to minimize downtime. Additionally, firms are adopting fully recyclable wrapping films to comply with sustainability regulations.

Year-on-Year Leaders

Technology suppliers should focus on automation, eco-friendly wrapping solutions, and smart packaging advancements to support the evolving flow wrap machines market. Partnering with food, pharmaceutical, and personal care brands will accelerate innovation and adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Bosch Packaging Technology, Syntegon, ULMA Packaging |

| Tier 2 | IMA Group, PFM Packaging, Coesia Group |

| Tier 3 | MULTIVAC, FUJI Machinery, Cavanna Packaging, Omori Machinery |

Top companies in the field are integrating their top machine technology with AI-powered automation, sustainable packaging materials, and high-speed processing capabilities. In addition to improving heat-sealing precision for better integrity of packaging, some companies are designing modular structures that allow rapid reconfiguration of a machine for different packaging formats. Businesses are also optimizing the conditions for use of films so that they can minimize the costs incurred on packaging material and improve their efficiency.

| Manufacturer | Latest Developments |

|---|---|

| Bosch Packaging | Launched AI-powered defect detection for high-speed wrapping in March 2024. |

| Syntegon | Developed recyclable wrapping film compatibility in April 2024. |

| ULMA Packaging | Expanded automated multi-lane flow wrappers in May 2024. |

| IMA Group | Released energy-efficient compact flow wrap machines in June 2024. |

| PFM Packaging | Strengthened modified atmosphere packaging (MAP) capabilities in July 2024. |

| Coesia Group | Introduced smart IoT-enabled wrappers in August 2024. |

| MULTIVAC | Pioneered paper-based flow wrap technology in September 2024. |

The flow wrap machines market is evolving as companies invest in AI-driven defect detection, high-speed automation, and sustainable materials. They are integrating next-generation servo motors to enhance precision and energy efficiency. Additionally, manufacturers are developing ultra-fast sealing mechanisms to increase productivity while reducing packaging waste. Businesses are also incorporating real-time data analytics to optimize workflow and improve overall equipment efficiency.

The focus of manufacturers will remain on continued integration of AI-based defect detection, modular machine design, and ultra-thin film technology developments. Meanwhile, companies will improve upon their high-speed automation for added production efficiency. Sustainable materials will have a broadened acceptance with increased regulatory need. Smart monitoring with predictive maintenance will ensure up times for machines. Furthermore, AI-based analytics will help streamline packaging practices and reduce material waste.

Leading players include Bosch Packaging Technology, Syntegon, ULMA Packaging, IMA Group, PFM Packaging, Coesia Group, and MULTIVAC.

The top 3 players collectively control 18% of the global market.

The market shows medium concentration, with top players holding 38%.

Key drivers include automation, sustainability, high-speed processing, and smart packaging solutions.

Explore Packaging Machinery Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.