The flip tops caps and closures industry is going to grow with manufacturers focusing on convenience, hygiene, and eco-friendliness. The rising demand is already compelling food & beverage, personal care, pharmaceuticals, and household product businesses to innovate through designs, recyclable materials, and precise mold techniques. Businesses are in the process of perfecting smart closures, leak-proof devices, and child-resistant features for enhanced safety and usability.

Investments in artificial intelligence-based quality control, automated assembly lines, and lightweight material innovations by the manufacturers ensure cost benefits and positive environmental impacts. Biodegradables are gradually replacing normal plastics by transforming the industry into evolutions involving post-consumer recycling (PCR) plastics and bio-derived resins.

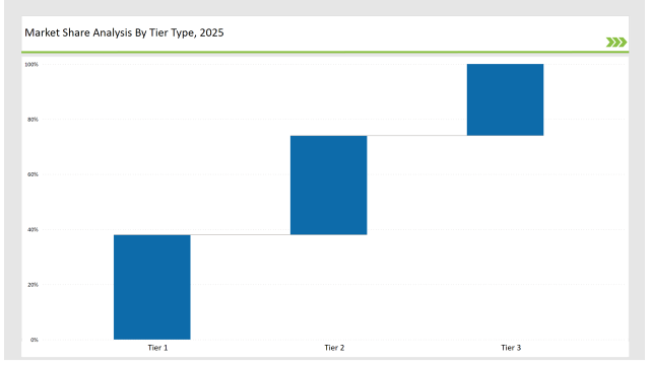

39% of the market concerning the participation of Tier 1 players, such as Berry Global and AptarGroup, is due to their high-performance solutions in closure performance, superior material engineering capability, and a worldwide supply network.

40% of the market captured by Tier 2 companies such as Bericap, ALPLA, and Mold-Rite Plastics, which are coming along with custom-price, cost-efficient, and special closures for different applications.

Regional and niche players occupy the last segment, Tier 3, with specialized focus on sustainable, tamper-proof, and ergonomic closures, which account for about 21% of the entire market. Localized production and a sustainable packaging solution are emphasized, and product differentiation is the focus of these firms.

Explore FMI!

Book a free demo

| Category | Market Share (%) |

|---|---|

| Top 3 (Berry Global, AptarGroup, Silgan Holdings) | 17% |

| Rest of Top 5 (Bericap, ALPLA) | 13% |

| Next 5 of Top 10 (Mold-Rite Plastics, United Caps, Closure Systems International, Phoenix Closures, Blackhawk Molding) | 9% |

The flip top caps and closures industry caters to different markets where superlative convenience, hygiene, and sustainability matter. Companies are designing closures with an eye to functionality and brand enhancement. Advanced sealing mechanisms are being incorporated to avoid leakage and secure product freshness. Easy-opening features are also being introduced by manufacturers for overall consumer convenience.

Manufacturers are working on optimizing flip top caps and closures with ultra-durable materials, leak-proof designs, and smart dispensing functions. They introduced self-sealing mechanisms for hygiene and contamination prevention. Further, ultra-lightweight closures are being developed with minimal plastic use while keeping maximum strength. Companies also incorporated tactile grip surfaces to assist users and ensure easy opening.

The flip top caps and closures industry is undergoing major changes through sustainability and automation. AI-assisted defect detection technologies in concert with lightweighting and solvent-free coatings that help recyclability are being implemented by the companies. Bio-resin solutions are being advanced in place of fossil fuel-based plastics. Manufacturers are now launching smart closures embedded with sensors to track freshness. Furthermore, the firms are innovating Resealable and multi-use closure designs to promote product longevity and thereby reduce waste.

Year-on-Year Leaders

Technology suppliers should focus on automation, smart packaging innovations, and sustainable material advancements to support the evolving flip top caps and closures market. Partnering with food, pharmaceutical, and personal care brands will drive innovation and adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Berry Global, AptarGroup, Silgan Holdings |

| Tier 2 | Bericap, ALPLA, Mold-Rite Plastics |

| Tier 3 | United Caps, Closure Systems International, Phoenix Closures, Blackhawk Molding |

Leading manufacturers are advancing flip top caps and closures technology with AI-powered production, sustainable materials, and smart packaging solutions. They are developing ultra-light closures to minimize plastic use while maintaining strength. Additionally, companies are integrating antimicrobial coatings to enhance hygiene and prevent contamination. Manufacturers are also adopting energy-efficient molding techniques to reduce carbon footprints.

| Manufacturer | Latest Developments |

|---|---|

| Berry Global | Launched lightweight PCR-based closures in March 2024. |

| AptarGroup | Developed child-resistant, tamper-proof closures in April 2024. |

| Silgan Holdings | Expanded high-barrier spill-proof closure solutions in May 2024. |

| Bericap | Released ergonomic, easy-dispensing caps in June 2024. |

| ALPLA | Strengthened biodegradable closure offerings in July 2024. |

| Mold-Rite Plastics | Introduced UV-resistant closures in August 2024. |

| United Caps | Pioneered smart NFC-enabled closures in September 2024. |

The flip top caps and closures market is evolving as companies invest in sustainable materials, AI-driven defect detection, and interactive packaging solutions. They are enhancing closure durability with reinforced hinge designs to improve longevity. Additionally, manufacturers are optimizing production processes to reduce energy consumption and material waste. Businesses are also integrating antimicrobial coatings to enhance hygiene and extend product shelf life.

Manufacturers will be integrating AI-based defect detection and high-barrier coatings along with smart dispensing technology. Companies will further develop ultra-light and sustainable designs to minimize the use of material. Businesses will also enhance child-resistant and tamper-proof closure features in compliance with regulations. The smart packaging improvements of freshness indicators and anti-counterfeiting features will gain traction. Also, AI plays an important role by analyzing performance for closures and improving efficiency in production.

Leading players include Berry Global, AptarGroup, Silgan Holdings, Bericap, ALPLA, Mold-Rite Plastics, and United Caps.

The top 3 players collectively control 17% of the global market.

The market shows medium concentration, with top players holding 39%.

Key drivers include sustainability, automation, tamper-evidence, and smart packaging solutions.

Nitrogen Flushing Machine Market Report – Trends, Size & Forecast 2025-2035

Pan Liner Market Insights – Demand, Growth & Industry Trends 2025-2035

Perfume Filling Machine Market Report – Trends, Demand & Industry Forecast 2025-2035

Molded Pulp Packaging Machines Market Analysis - Growth & Forecast 2025 to 2035

Packaging Tensioner Market Analysis - Growth & Forecast 2025 to 2035

Packaging Films Market Analysis by Product Type, Material Type and End Use Through 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.