The flex pack coating industry is gaining momentum with brands and manufacturers focusing increasingly on sustainability, durability, and aesthetic appeal for flexible packaging. Recent levels of demand have provoked innovations in high-barrier coatings, bio-based materials, and digital printing applied in food, pharmaceutical, personal care, and industrial sectors. Perhaps a few have adopted solventless coatings, and some have antimicrobial layers while yet others are including smart packaging features to ensure enhanced protection of products and consumer interaction.

Manufacturers, on their part, are undertaking the investment to operationalize AI for quality control, speed up the application processes, and set green coating technologies in place for efficiency and environment concerns. These coatings will most probably include compostable, heat-resistant, and oxygen-barrier coatings for shelf-life extension while reducing plastic usage.

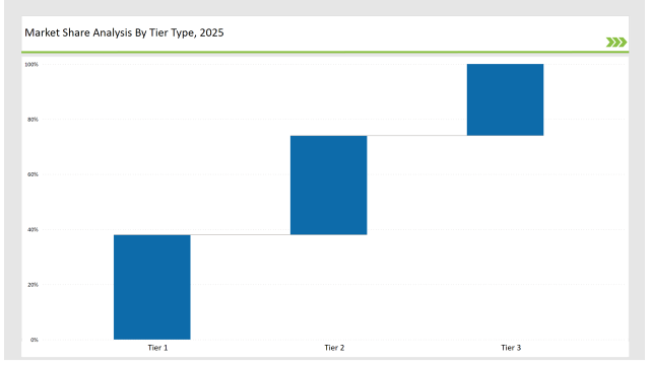

Tier 1 players, comprised of Amcor, Berry Global, and Mondi Group, own 38% of the markets because of their leadership in high-performance coatings and sustainable material solutions with excellent distribution networks.

Tier 2 companies such as Avery Dennison, UPM Raflatac, and Siegwerk offer technologies and products to suit the requirements of food, healthcare, and e-commerce applications by developing cost-effective, high-barrier, and digitally printable coatings, hence maintaining their 36% market share.

Tier 3 is made up of regional and niche players specializing in biodegradable, recyclable, and smart coatings and accounting for 26% of the market share. Adopting a local sustainable production strategy, these companies encompass a sustainability-driven innovation agenda and custom formulations.

Explore FMI!

Book a free demo

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Amcor, Berry Global, Mondi Group) | 18% |

| Rest of Top 5 (Avery Dennison, UPM Raflatac) | 12% |

| Next 5 of Top 10 (Siegwerk, Flint Group, Constantia Flexibles, Huhtamaki, Sonoco) | 8% |

The flex pack coating industry serves multiple sectors where product protection, sustainability, and branding are critical. Companies are developing advanced coating technologies to meet evolving consumer and regulatory demands. They are enhancing coatings with oxygen and moisture barriers to improve product longevity. Additionally, businesses are integrating bio-based coatings to align with sustainability goals and reduce reliance on petroleum-based materials.

Manufacturers are optimizing flex pack coatings with sustainability-driven solutions, advanced protective layers, and smart packaging technologies. They are incorporating nanocoatings to enhance moisture resistance and improve food preservation. Additionally, companies are developing high-performance coatings that maintain flexibility while increasing puncture resistance. Businesses are also integrating odor-barrier coatings to improve product freshness and consumer experience.

Sustainability and digital transformation are bringing in a new order in the flexible pack coating industry. Companies are using approaches and solutions like AI-based defect detection, bio-based coatings, and smart packaging solutions to increase the attractiveness and the compliances of their product. Companies are also coming up with ultra-thin barrier coatings to replace multilayer plastics. Suppliers are launching solvent-free as well as water-based coatings in the market. Companies are in addition equipping their products with RFID and NFC-enabled coatings for real-time tracking and authentication.

Year-on-Year Leaders

Technology suppliers should focus on automation, bio-based coating innovations, and high-speed application techniques to support the evolving flex pack coating market. Partnering with food, pharmaceutical, and personal care brands will accelerate adoption and market expansion.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Amcor, Berry Global, Mondi Group |

| Tier 2 | Avery Dennison, UPM Raflatac, Siegwerk |

| Tier 3 | Flint Group, Constantia Flexibles, Huhtamaki, Sonoco |

Leading manufacturers are advancing flex pack coating technology with AI-powered production, eco-friendly materials, and digital branding solutions. They are developing ultra-thin coatings to enhance flexibility without compromising strength. Additionally, companies are incorporating self-healing coatings to improve durability and extend product lifespan. Manufacturers are also optimizing energy-efficient curing techniques to reduce processing time and lower environmental impact.

| Manufacturer | Latest Developments |

|---|---|

| Amcor | Launched fully recyclable high-barrier coatings in March 2024. |

| Berry Global | Developed solvent-free, antimicrobial coatings in April 2024. |

| Mondi Group | Expanded compostable and water-resistant coatings in May 2024. |

| Avery Dennison | Released heat-sealable e-commerce coatings in June 2024. |

| UPM Raflatac | Strengthened linerless sustainable label coatings in July 2024. |

| Siegwerk | Introduced digital-print compatible, food-safe coatings in August 2024. |

| Flint Group | Pioneered high-gloss, tactile coatings for premium packaging in September 2024. |

The flex pack coating market is evolving as companies invest in bio-based materials, AI-driven defect detection, and interactive packaging solutions. They are incorporating nanotechnology to enhance barrier properties and improve product shelf life. Additionally, manufacturers are developing ultra-thin coatings that maintain durability while reducing material use. Businesses are also optimizing anti-counterfeit coatings to strengthen security in high-value packaging.

Manufacturers will be optimizing AI-powered quality control, while introducing high-barrier bio-based coatings and enhancements in smart packaging. The companies will make advancements in solvent-free and water-based formulations to comply with sustainability regulations. The firms will further develop digital-printable coatings for mass customization. Use of coatings that integrate RFID and NFC will allow better supply chain visibility. Moreover, AI analytics would fasten up the coating applications, which, in turn, will increase efficiency in production and decrease wastage of materials.

Leading players include Amcor, Berry Global, Mondi Group, Avery Dennison, UPM Raflatac, Siegwerk, and Flint Group.

The top 3 players collectively control 18% of the global market.

The market shows medium concentration, with top players holding 38%.

Key drivers include sustainability, digital printing, high-barrier coatings, and automation.

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.