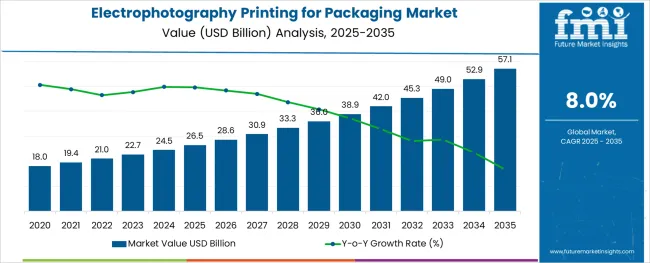

The Electrophotography Printing for Packaging Market is estimated to be valued at USD 26.5 billion in 2025 and is projected to reach USD 57.1 billion by 2035, registering a compound annual growth rate (CAGR) of 8.0% over the forecast period.

The electrophotography printing for packaging market is expanding steadily, fueled by the increasing need for on-demand, variable data printing and brand personalization. As packaging becomes a key medium for consumer engagement and regulatory communication, electrophotographic technologies offer consistent print quality, fine detail reproduction, and compatibility with a range of substrates.

The market is benefitting from the shift toward digital printing methods that reduce waste, speed up turnaround times, and eliminate the need for printing plates. Advancements in toner chemistry and fusing processes are also supporting wider adoption in food, beverage, pharmaceutical, and cosmetic packaging applications

The technology’s ability to comply with low-migration ink standards and food safety regulations is further accelerating its use in sensitive product categories. Future growth is expected to be supported by the development of electrophotographic systems capable of handling flexible packaging materials and the integration of workflow automation tools that enable cost-effective mass customization.

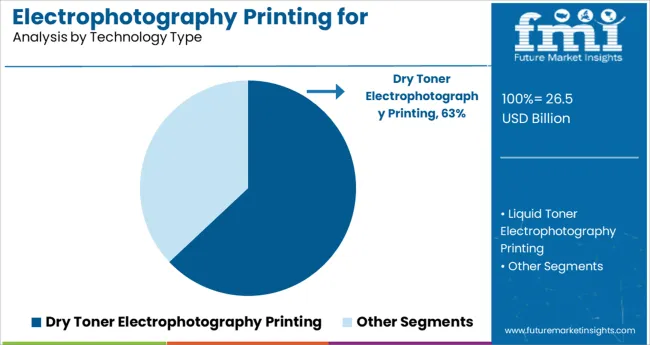

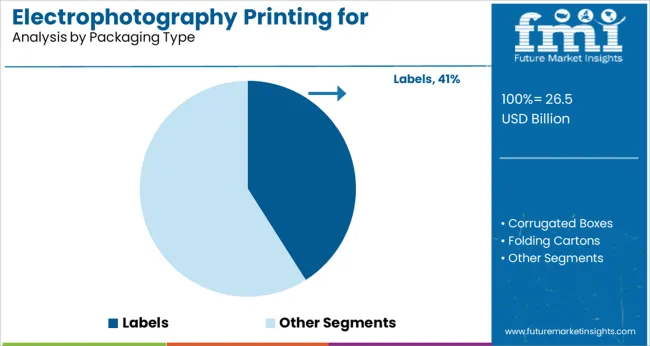

The market is segmented by Technology Type, Packaging Type, and End User Base and region. By Technology Type, the market is divided into Dry Toner Electrophotography Printing and Liquid Toner Electrophotography Printing. In terms of Packaging Type, the market is classified into Labels, Corrugated Boxes, Folding Cartons, Bags & Sacks, and Others.

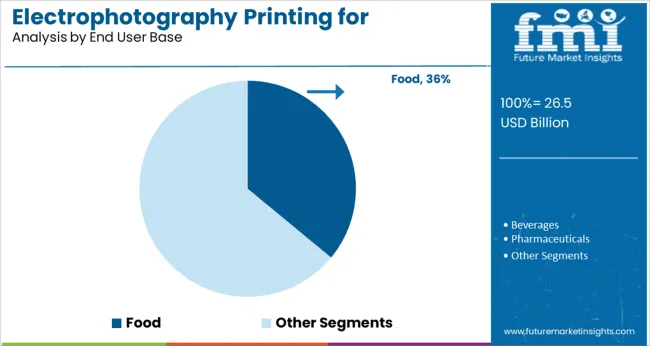

Based on End User Base, the market is segmented into Food, Beverages, Pharmaceuticals, Electronic Components, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Dry toner electrophotography printing is projected to hold 63.0% of the total market revenue in 2025, positioning it as the leading technology type. This segment’s dominance is being driven by its ability to deliver sharp image quality, substrate versatility, and fast-drying output, which are critical for high-throughput packaging lines. Dry toner systems offer minimal ink penetration and excellent adhesion on coated and uncoated materials, making them suitable for diverse packaging formats including folding cartons and synthetic labels.

The absence of liquid solvents enhances sustainability and safety, particularly for food-grade and pharmaceutical applications. Moreover, the simplified maintenance, minimal setup time, and compatibility with short-run and variable data printing workflows have made dry toner systems an attractive choice for converters and brand owners aiming for quick market responsiveness.

As packaging personalization and SKU proliferation rise, dry toner electrophotography is expected to remain the preferred technology for consistent, durable, and regulation-compliant packaging prints.

Labels are expected to account for 41.0% of the market revenue in 2025, making them the dominant packaging type within the electrophotography printing segment. This leadership is being attributed to the growing demand for digitally printed labels that support product authentication, traceability, and consumer engagement. The ability of electrophotographic printing to produce high-resolution graphics, variable text, and scannable codes in a single pass has significantly improved production efficiency for label converters.

Labels serve as critical branding elements across a wide variety of industries and are often required in small batches with rapid turnaround, aligning well with the capabilities of electrophotography. Furthermore, advancements in pressure-sensitive label substrates and high-speed inspection systems are complementing the adoption of this printing technology in pharmaceutical, food, beverage, and personal care markets.

With the continued growth of e-commerce and SKU diversification, demand for visually appealing and information-rich labels is expected to further solidify this segment's top position.

The food industry is projected to lead the electrophotography printing for packaging market with a 36.0% revenue share in 2025. This dominance is being fueled by stringent labeling requirements, increasing demand for shelf-ready packaging, and a strong emphasis on product differentiation. Electrophotography offers food brands the ability to deliver vibrant, legible, and regulation-compliant packaging prints with rapid design changeover and minimal waste.

Dry toner systems, in particular, have gained favor due to their low-migration properties and adherence to global food safety standards. The trend toward clean-labeling, functional packaging, and personalized branding has led food manufacturers to seek printing solutions that support flexibility without compromising on quality or compliance.

In recent few years, the packaging industry has seen a significant demand for increasing application of digital printing techniques. Electrophotography printing for packaging is one of the most preferred digital printing technology.

Electrophotography printing for packaging improves the efficiency of the work process, quicker marketing and empowers innovative marketing. Due to the higher quality of printing and more efficient working speed, the market for electrophotography printing has seen substantial growth over the forecast period.

Electrophotography printing consists of two types, dry toner electrophotography printing, and liquid toner electrophotography printing. Both the type of electrophotography printing have their unique advantages. Liquid electrophotography printing for packaging has faster print speed with high output as compared to dry toner electrophotography printing.

While in dry toner electrophotography printing, the toner is directly printed from air to substrate which would decrease the drying time as compared to liquid toner electrophotography. All these are the few of the key factors driving the market for electrophotography printing for packaging.

Electrophotography printing for packaging is estimated to witness tremendous growth of 14% over the forecast period 2020-2025. Furthermore, the preference for electrophotography printing for packaging due to several values added features such as faster printing speed with high output are driving the market.

In addition, customers are mainly focusing on the print quality; as a result of the better print quality of electrophotography printing for packaging the market is expected to have subsequent growth. All these factors create the growth opportunity for electrophotography printing for the packaging market.

Moreover, the market for electrophotography printing for packaging is restricted by digital printing which incurs high per unit cost for larger volumes, and secondary packaging is preferably printed using conventional printing technology.

Social media trends such as unboxing and sharing brand preference are challenging the labeling and packaging market for electrophotography printing to find branding solutions through the printing of secondary packaging.

The global electrophotography printing for packaging market can be divided into seven major regions which are as follows -

North America is expected to dominate the electrophotography printing for packaging market followed by Europe. Asia-Pacific is anticipated to be the fastest growing market due to the preference for electrophotography printing for packaging.

Europe is expected to have a steady growth of electrophotography printing for packaging market share over the forecast period. Latin America has shown healthy growth of electrophotography printing for the packaging market. The Middle East & Africa region have seen a stagnant growth of electrophotography printing for the packaging market.

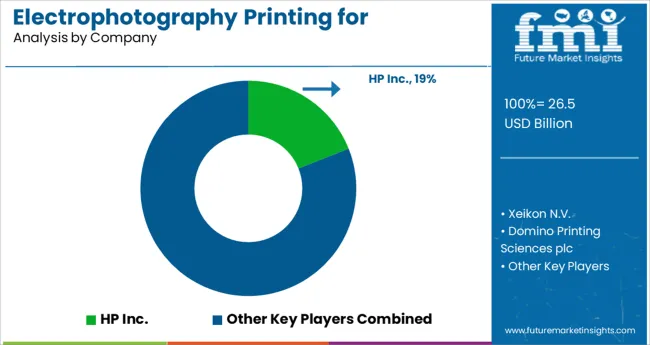

Few of the key players in the electrophotography printing for packaging market are HP Inc., Xeikon N.V., Domino Printing Sciences plc, Eastman Kodak Company, Seiko Epson Corporation, Tailored Label Products, Inc., Quad/Graphics, Inc., Creative Labels Inc., DS Smith Plc, Reynders Label Printing, Traco Manufacturing, Inc., Thimm Group GmbH + Co. KG, Elanders AB, Ws Packaging Group, Inc., Colordruck Baiersbronn W. Mack GmbH & Co. KG, etc.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global electrophotography printing for packaging market is estimated to be valued at USD 26.5 billion in 2025.

It is projected to reach USD 57.1 billion by 2035.

The market is expected to grow at a 8.0% CAGR between 2025 and 2035.

The key product types are dry toner electrophotography printing and liquid toner electrophotography printing.

labels segment is expected to dominate with a 41.0% industry share in 2025.

Explore Similar Insights

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.