The egg carton industry is expanding as sustainability, durability, and branding become top priorities for producers. With rising demand from poultry farms, retail stores, and e-commerce platforms, manufacturers are focusing on recyclable, compostable, and biodegradable materials. Companies are incorporating molded fiber, PET plastic, and foam alternatives to enhance egg protection while reducing environmental impact.

Manufacturers are adopting AI-driven quality control, automation in molding processes, and digital printing for custom branding. The industry is shifting toward lightweight, moisture-resistant cartons with tamper-proof features and smart tracking technologies to improve supply chain transparency.

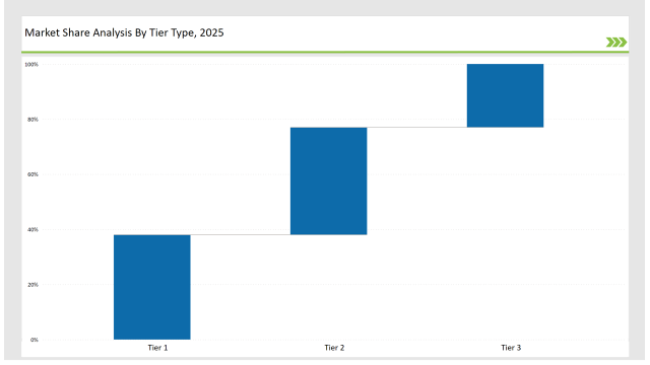

Tier 1 companies, such as Hartmann, Huhtamaki, and Cascades, control 38% of the market based on their superiority in molded fiber technology, large-scale production capabilities, and global distribution channels.

Tier 2 companies, such as Tekni-Plex, Pactiv Evergreen, and DFM Packaging, capture 39% of the market by offering cost-effective, high-strength, and customizable egg cartons for regional and mid-size producers.

Tier 3 represents regional and specialty players offering creative, compostable, and digitally printed egg cartons, controlling 23% of the market. These firms concentrate on local production, environmental-friendly designs, and industry-customized solutions.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

Global Market Share by Key Players (2025)

| Category | Market Share(%) |

|---|---|

| Top 3 (Hartmann,Huhtamaki,Cascades) | 18% |

| Rest of Top 5 (Tekni-Plex,Pactiv Evergreen) | 12% |

| Next 5 of Top 10 (DFM Packaging,CDL Omnipac,Europack,Al Ghadeer Group,Primapack) | 8% |

The egg carton industry caters to many industries wherein safety, sustainability, and branding become paramount. Companies are working towards developing innovative carton solutions to cater to industry requirements. They are incorporating advanced shock-absorption technology to avoid breakage during transport. Furthermore, manufacturers design stackable cartons with reinforced edges for better storage and handling. Businesses are also increasing visual aesthetics through high-resolution digital printing for custom branding and product information.

To optimize egg carton performance, manufacturers are employing moisture-resistant coatings, reinforcement at the edges, and smart tracking solutions. Antimicrobial coatings are also being applied to maximize hygiene and safety in food packaging. On the product side, tamper-evident closures are being developed to provide additional security while also preventing contamination. Finally, companies are applying AI techniques to detect defects and ensure uniform quality through a high-speed production line.

Sustainability and automation are reshaping the egg carton industry. Companies are developing AI-driven defect detection, high-speed molding lines, and tamper-evident seals to enhance packaging security. Businesses are investing in water-based printing to improve recyclability while maintaining vibrant branding. Manufacturers are expanding their range of moisture-resistant fiber cartons to prevent carton deterioration in humid environments. Additionally, firms are integrating QR codes and RFID tracking to provide real-time supply chain monitoring.

Technology suppliers should focus on automation, smart packaging, and sustainable materials to support the evolving egg carton market. Partnering with poultry farms, grocery retailers, and e-commerce brands will drive adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Hartmann, Huhtamaki, Cascades |

| Tier 2 | Tekni-Plex, Pactiv Evergreen, DFM Packaging |

| Tier 3 | CDL Omnipac, Europack, Al Ghadeer Group, Primapack |

Egg carton technology now takes form with AI-driven molding, moisture proof coatings, and the most sustainable materials by leading manufacturers in the industry. High-strength carton structures are being developed to improve stacking efficiency and minimize breakage. In addition, companies also add more ventilation features to improve egg freshness and increase airflow. Further, plant-based coatings have been developed by manufacturers for replacing synthetic barriers, thus benefiting recyclability further.

| Manufacturer | Latest Developments |

|---|---|

| Hartmann | Launched fully recyclable molded fiber cartons in March 2024. |

| Huhtamaki | Developed moisture-resistant fiber packaging in April 2024. |

| Cascades | Expanded compostable egg carton solutions in May 2024. |

| Tekni-Plex | Released clear PET and RPET plastic egg cartons in June 2024. |

| Pactiv Evergreen | Strengthened tamper-proof and impact-resistant designs in July 2024. |

| DFM Packaging | Introduced digitally printed branding solutions in August 2024. |

| CDL Omnipac | Pioneered RFID-enabled smart tracking cartons in September 2024. |

Evolution of the egg carton market has been witnessed with companies investing into sustainable materials, AI-based production, and smart packaging solutions. They are designing lightweight and strong carton designs to reduce material use while giving the required protection. In addition, companies are adopting high-speed molding methods to enhance efficiency and reduce production costs. In addition, manufacturers are employing UV-resistant coatings to offer protection to the cartons in extreme storage conditions.

The industry will continue integrating AI-driven molding technology, sustainable coatings, and digital tracking features. Manufacturers will refine moisture-resistant cartons to prevent deterioration. Businesses will adopt smart labeling to enhance traceability and consumer engagement. Companies will invest in high-speed automation to improve production efficiency. Firms will expand their use of biodegradable and compostable materials to meet eco-conscious consumer demand. Additionally, enhanced carton reinforcement techniques will improve egg protection during transit and storage.

Leading players include Hartmann, Huhtamaki, Cascades, Tekni-Plex, Pactiv Evergreen, DFM Packaging, and CDL Omnipac.

The top 3 players collectively control 18% of the global market.

The market shows medium concentration, with top players holding 38%.

Key drivers include sustainability, smart packaging, digital printing, and automation.

Explore Packaging Formats Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.