The disposable plastic pallet industry is acquiring pace due to increasing demand from the logistics, food & beverage, and pharmaceutical sectors for lighter, cost-efficient, and hygiene pallet solutions. Companies are adopting recyclable material, automation, and durable design to increase the sustainability and efficiency of operations. Optimization of production with reduced cost and improved consistency of the final product can be achieved through automation and more complex manufacturing techniques.

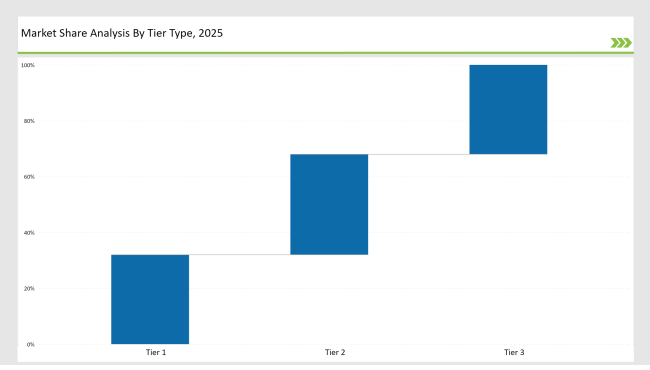

Tier 1 companies, including Schoeller Allibert, ORBIS Corporation, and Loscam, also have the market share of 32% with high end manufacturing process and wide networks with the introduction of new technology.

Tier 2 companies- CABKA Group, Rehrig Pacific, and Craemer- hold a 36% share. Its business solutions support mid-level customers who are budgeted yet rugged disposable plastic pallets. It further meets the compliance and sustainability standards for the company.

Tier 3 are regional and niche producers of reusable, lightweight, and customized plastic pallets. These make up 32% of the market and target the local supply chains with flexible methods of production.Vendor Performance

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

| Category | Market Share (%) |

|---|---|

| Top 3 (Schoeller Allibert, ORBIS Corporation, Loscam) | 19% |

| Rest of Top 5 (CABKA Group, Rehrig Pacific) | 8% |

| Next 5 of Top 10 (Craemer, Buckhorn, Greystone Logistics, Monoflo International, Allied Plastics) | 5% |

Disposable plastic pallets serve industries that demand cost-effective, hygienic, and durable material handling solutions. Growth in logistics, food distribution, and pharmaceuticals increases demand for lightweight and reusable pallets.

Manufacturers are innovating to enhance durability, reduce costs, and improve sustainability in plastic pallet production.

Manufacturers are investing in automation, using eco-friendly materials, and introducing smart tracking systems to remain ahead in the race. Companies develop recyclability, increase durability, and reduce environmental footprint. Sophisticated techniques such as injection molding and thermoforming make these processes efficient and cost-effective.

Year-on-Year Leaders

Technology suppliers should focus on developing smart tracking features, automation-friendly designs, and eco-friendly material solutions to align with market trends. Collaborations with raw material suppliers can accelerate innovation and improve cost-effectiveness.

Check Free Sample Report & Save 40%!

Select your niche segments and personalize your insights for smart savings. Cut costs now!

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Schoeller Allibert, ORBIS Corporation, Loscam |

| Tier 2 | CABKA Group, Rehrig Pacific |

| Tier 3 | Craemer, Buckhorn, Greystone Logistics, Monoflo International, Allied Plastics |

Leading manufacturers are enhancing sustainability, improving material strength, and integrating automation for efficient logistics handling.

| Manufacturer | Latest Developments |

|---|---|

| Schoeller Allibert | Developed lightweight, high-durability plastic pallets in March 2024. |

| ORBIS Corporation | Expanded its range of reusable plastic pallets in August 2023. |

| Loscam | Launched space-saving, nestable pallet designs in May 2024. |

| CABKA Group | Focused on sustainability with fully recycled plastic pallet solutions. |

| Rehrig Pacific | Introduced antimicrobial plastic pallets for hygiene-sensitive industries. |

| Craemer | Strengthened its portfolio with heavy-duty industrial pallets. |

| Buckhorn | Developed customized pallet solutions for automotive and retail supply chains. |

| Greystone Logistics | Advanced high-load capacity pallets for e-commerce distribution centers. |

The competitive landscape in the disposable plastic pallet market is evolving as key players prioritize sustainability, automation, and enhanced durability to maintain a strong market position.

Companies will implement new intelligent tracking technologies on plastic pallets in order to increase visibility and efficiency in supply chains. Sustainability will lie in even further use of more recycled and biodegradable materials. Manufacturing will get automated to cut costs and produce faster.

Latest polymer formulations will increase pallet durability and weight capacity. Businesses will adopt RFID-enabled pallets to easily manage inventory. Hygienic pallets will come into demand in food and pharmaceutical industries. E-commerce and logistics will continue to be the drivers for the demand for lightweight, durable plastic pallets.

Leading players include Schoeller Allibert, ORBIS Corporation, Loscam, CABKA Group, and Rehrig Pacific.

The top 3 players collectively control 19% of the global market.

The market shows medium concentration, with top players holding 32%.

Key drivers include sustainability, automation, and supply chain optimization.

Explore Packaging Formats Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.