The deblistering machines market is expanding rapidly as industries prioritize efficiency, accuracy, and sustainability in recovering and repackaging medications. Manufacturers are developing new machines that make tablet and capsule recovery easier and minimize waste. The market is expected to reach over USD 297.7 million by 2035, growing at a compound annual growth rate (CAGR) of 5%.

With increasing pharmaceutical production across the globe, the demand for accuracy and compliance in the processing of expired or damaged blister packs is pushing the use of deblistering machines. Companies are coming up with solutions that meet these requirements but also focus on operator safety and environmental impact.

| Attribute | Details |

|---|---|

| Projected Value by 2035 | USD 297.7 million |

| CAGR (2025 to 2035) | 5% |

Explore FMI!

Book a free demo

Summary

The SWOT analysis highlights the strategies and strengths of leading players in the deblistering machines market. Companies like Sepha Ltd., Omnicell, and RBP Bauer are leveraging innovation, automation, and customization to maintain their market positions. However, challenges such as high costs, regional competition, and fluctuating raw material prices create opportunities for sustainable designs and emerging market expansions.

Sepha Ltd.

Sepha Ltd. is at the forefront in providing high-end deblistering machines that emphasize accuracy and safety. Its key strength is in being innovative, distributing products worldwide, but high prices could dissuade some cost-conscious buyers. The potential of the business to grow lies in entering the untapped emerging markets and catering to the increased desire for automation; but regional manufacturers also compete.

Omnicell Inc.

Omnicell is strong on durable, automation-compatible deblistering machines that help in streamlining pharmaceutical workflows. Reliability and user-friendly designs have been the hallmark of the company. However, limited penetration in fast-growing regions like Asia-Pacific can be a limiting factor for its growth. There are opportunities for developing eco-friendly solutions, and regulatory changes pose a challenge.

RBP Bauer

RBP Bauer is known for producing efficient and customizable deblistering machines. Its strong customer support and innovative solutions make it a trusted name in the industry. However, high production costs for advanced models can limit its market share. Opportunities lie in introducing sustainable designs, while fluctuating raw material prices and evolving compliance standards are potential threats.

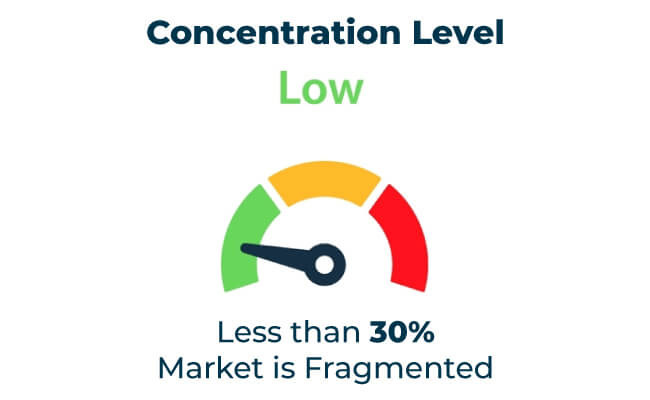

| Category | Market Share (%) |

|---|---|

| Top 3 Players (Sepha, Omnicell, RBP Bauer) | 16% |

| Rest of Top 5 Players (ACG Worldwide, Uhlmann) | 06% |

| Next 5 of Top 10 Players | 07% |

Type of Player & Industry Share

| Type of Player | Market Share (%) |

|---|---|

| Top 10 Players | 29% |

| Next 20 Players | 45% |

| Remaining Players | 26% |

North America implements strict compliance standards for pharmaceutical packaging, ensuring that all products meet rigorous safety and quality requirements. Europe stands out for its sustainability-focused regulations and innovative practices that prioritize eco-friendly solutions in pharmaceutical packaging. Meanwhile, Asia-Pacific is experiencing rapid growth, driven by an increase in pharmaceutical production and expanding export activities, making it a key region for market expansion.

Emerging markets in Asia-Pacific, Africa, and Latin America present significant growth potential. Expanding pharmaceutical manufacturing in these regions drives demand for efficient deblistering solutions. Exporters that align with local regulations and sustainability goals can gain a competitive edge.

The regional analysis of the deblistering machines market uncovers diverse growth trends shaped by the distinct priorities of automation, stringent regulatory compliance, and sustainability initiatives across different geographic regions. Each area exhibits unique drivers of demand, highlighting opportunities for manufacturers to tailor their solutions to regional needs.

| Region | North America |

|---|---|

| Market Share (%) | 40% |

| Key Drivers | Focuses on automation and regulatory compliance. |

| Region | Europe |

|---|---|

| Market Share (%) | 35% |

| Key Drivers | Leads with sustainable and advanced deblistering solutions. |

| Region | Asia-Pacific |

|---|---|

| Market Share (%) | 20% |

| Key Drivers | Experiences rapid growth due to pharmaceutical production expansion. |

| Region | Other Regions |

|---|---|

| Market Share (%) | 5% |

| Key Drivers | Demand grows for cost-effective, efficient machines in emerging markets |

The deblistering machines market will continue to grow through advancements in automation, smart technologies, and sustainability. Companies focusing on eco-friendly practices, efficient designs, and global market expansion will strengthen their market positions. Collaboration with pharmaceutical companies and regulatory bodies will further enhance adoption.

Summary

This section provides a detailed breakdown of the key players in the deblistering machines market by tier, highlighting their strengths and market positions. Tier 1 companies like Sepha, Omnicell, and RBP Bauer lead the market with advanced, customizable solutions and strong global presence. Tier 2 and Tier 3 players focus on niche applications and regional dominance, offering opportunities for growth through innovation and sustainability.

| Tier | Key Companies |

|---|---|

| Tier 1 | Sepha, Omnicell, RBP Bauer |

| Tier 2 | ACG Worldwide, Uhlmann |

| Tier 3 | Pharmapack, Jornen Machinery |

The deblistering machines market is set for sustained growth as pharmaceutical production, compliance needs, and sustainability initiatives drive demand. Companies prioritizing eco-friendly designs, advanced technologies, and global market expansion will lead the industry. Collaboration with stakeholders in pharmaceutical packaging will unlock further opportunities.

Key Definitions

Abbreviations

Methodology

This report integrates primary research, secondary data, and expert insights. Findings are validated through interviews with industry professionals and end-users to ensure accuracy and reliability.

The deblistering machines market includes the development and use of devices designed to recover medications from blister packs efficiently and sustainably. These machines prioritize precision, safety, and environmental responsibility.

Deblistering machines are used to recover medications from blister packs efficiently while minimizing waste

Manufacturers use recyclable components, adopt energy-efficient technologies, and design machines to reduce material waste.

North America and Europe lead due to advanced manufacturing capabilities and strict compliance standards, while Asia-Pacific is rapidly growing.

Challenges include high production costs, regulatory complexities, and gaps in recycling infrastructure.

Automation-ready systems, IoT-enabled machines, and eco-friendly designs are driving innovation in the deblistering machines market.

BOPP Film Market Analysis by Thickness, Packaging Format, and End-use Industry Through 2025 to 2035

Korea Tape Dispenser Market Analysis by Material, Product Type, Technology, End Use, and Region through 2025 to 2035

Japan Heavy-duty Corrugated Packaging Market Analysis based on Product Type, Board type, Capacity, End use and City through 2025 to 2035

Corrugated Board Market Analysis by Material and Application Through 2035

Waterproof Packaging Market Trends - Demand & Industry Forecast 2025 to 2035

Thermochromic Labels Market Insights - Innovations & Growth 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.