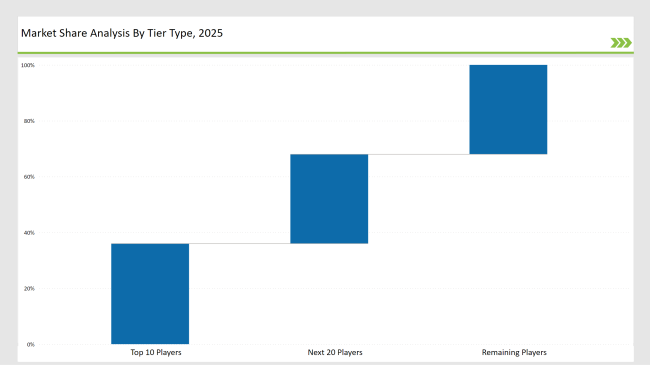

The demand for lightweight, strong, and environment-friendly packaging is increasing in the cubitainer market, thereby expanding its growth. This market is categorized into three levels of production capacity and market share. Leading companies such as Smurfit Kappa, Sealed Air, and DS Smith control 36% of the market, leveraging advanced manufacturing technologies, strong global distribution networks, and continuous innovation.

Tier 2 players, including Liqui-Box, Scholle IPN, and Rapak, hold 32% of the market. These companies offer value-added, lower-cost solutions of cubitainers customized for specific applications across different markets that meet the requirements of mid-sized enterprises. The Tier 3 players account for 32%, which includes regional and specialty manufacturers focused on applications in industries, such as pharmaceuticals, food, and industrial chemicals.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

Global Market Share by Key Players

| Category | Market Share (%) |

|---|---|

| Top 3 (Smurfit Kappa, Sealed Air, DS Smith) | 20% |

| Rest of Top 5 (Liqui-Box, Scholle IPN) | 12% |

| Next 5 of Top 10 (Rapak, CDF Corporation, ChangZhou, Zacros, Optopack) | 4% |

The cubitainer market serves various industries, including:

To meet industry demands, companies focus on:

Companies are looking into advanced material technologies and environmentally friendly alternatives as a means to meet the strict environmental regulations while also keeping the consumer in line with their wants.

Manufacturers are investing into automation, quality control driven through AI, sustainable materials, to stay ahead in the game. Strategic partnerships are producing more innovations in cubitainer solutions such as efficiency, durability, among others.

Year-on-Year Leaders

Check Free Sample Report & Save 40%!

Select your niche segments and personalize your insights for smart savings. Cut costs now!

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Smurfit Kappa, Sealed Air, DS Smith |

| Tier 2 | Liqui-Box, Scholle IPN, Rapak |

| Tier 3 | CDF Corporation, ChangZhou, Zacros, Optopack |

| Manufacturer | Latest Developments |

|---|---|

| Smurfit Kappa | In March 2024, expanded recyclable cubitainer solutions for multiple applications. |

| Sealed Air | In August 2023, launched lightweight, durable cubitainers for industrial packaging. |

| DS Smith | In May 2024, introduced high-strength, eco-friendly cubitainers. |

| Liqui-Box | In Nov 2023, developed ultra-flexible cubitainers for the beverage industry. |

| Scholle IPN | In Feb 2024, invested in AI-driven production systems for improved sustainability. |

| Rapak | In Jan 2024, expanded production to meet increasing global demand for liquid packaging. |

| CDF Corporation | In Apr 2024, introduced innovative, high-barrier cubitainers for chemical storage. |

| Optopack | In June 2024, developed compostable cubitainer laminates for food and beverage sectors. |

Automation, material innovations, and sustainability efforts will continue to shape the cubitainer industry. Companies are pursuing blockchain integration for better traceability, closed-loop recycling, and smart packaging solutions for efficiency and less environmental damage. Additionally, advancements in bio-based resins are making cubitainers more environmentally friendly. The increased use of AI-driven quality control systems is improving production accuracy and reducing material waste.

Leading players include Smurfit Kappa, Sealed Air, DS Smith, Liqui-Box, and Scholle IPN.

The top 3 players collectively account for approximately 20% of the global market.

The market concentration is considered medium, with top players holding 36%.

Key drivers include sustainability, automation, material innovation, and regulatory compliance.

Asia-Pacific and Latin America are expected to lead in growth, while Europe and North America focus on regulatory compliance and sustainable solutions.

Explore Function-driven Packaging Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.