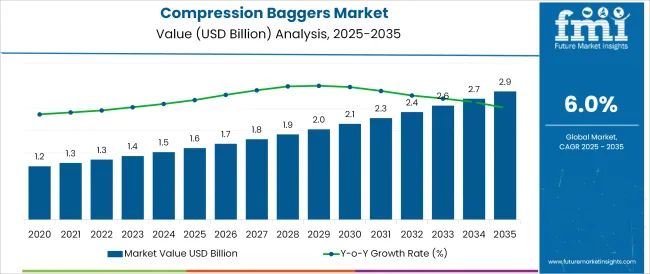

The Compression Baggers Market is estimated to be valued at USD 1.6 billion in 2025 and is projected to reach USD 2.9 billion by 2035, registering a compound annual growth rate (CAGR) of 6.0% over the forecast period.

The compression baggers market is experiencing consistent growth as industries prioritize efficiency, waste reduction, and improved packaging integrity. Demand has been shaped by operational needs for compact, secure packaging solutions that lower storage and transportation costs while ensuring product protection.

Adoption is being fueled by the rise of automation in manufacturing and packaging environments, which has increased throughput and reduced human error.

Future opportunities are anticipated to emerge from technological advancements enabling greater customization, integration with digital monitoring systems, and compliance with increasingly stringent hygiene and safety regulations. These factors collectively are paving the way for broader acceptance of compression bagging technologies across a diverse set of industries, with notable traction in sectors demanding high volume, reliable, and space saving packaging solutions.

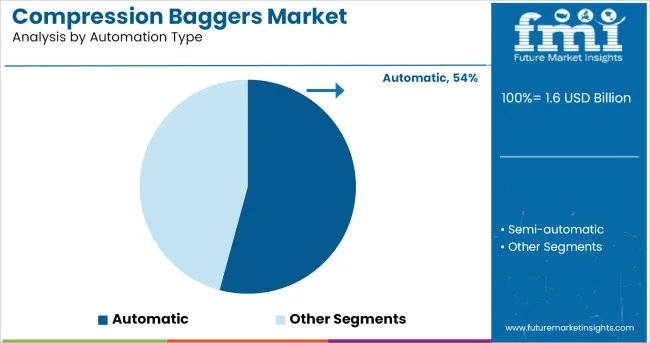

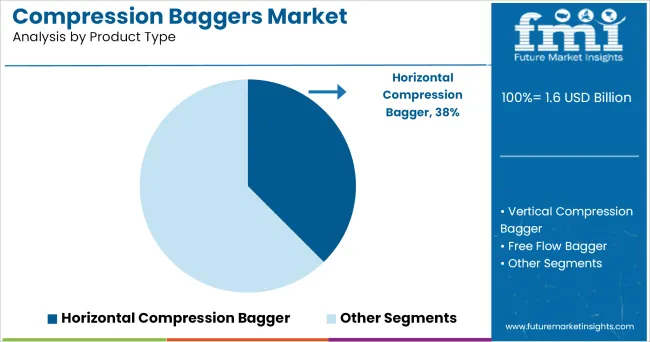

The market is segmented by Automation Type, Product Type, and End Use and region. By Automation Type, the market is divided into Automatic and Semi-automatic. In terms of Product Type, the market is classified into Horizontal Compression Bagger, Vertical Compression Bagger, Free Flow Bagger, and Light Compression Bagger.

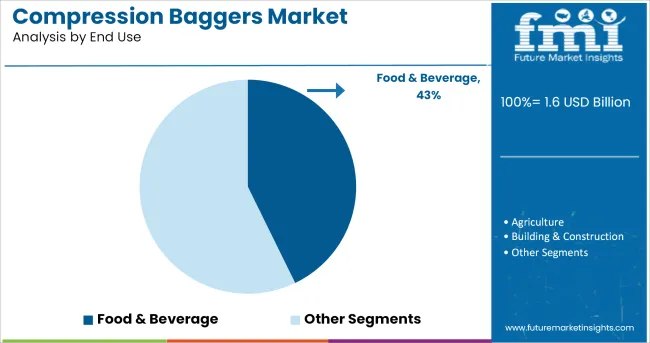

Based on End Use, the market is segmented into Food & Beverage, Agriculture, Building & Construction, Pharmaceutical, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by automation type, the automatic segment is expected to hold 54.2% of the total market revenue in 2025, positioning itself as the leading automation category. This dominance has been supported by the drive for greater operational efficiency, reduced labor dependency, and consistency in output quality.

Automatic compression baggers have enabled manufacturers to achieve higher production rates, improved precision, and minimized downtime, thereby enhancing overall profitability. Their ability to integrate seamlessly with upstream and downstream processes has reinforced their appeal among industries seeking to optimize packaging lines.

Additionally, the rising cost of labor and the growing emphasis on workplace safety have accelerated investments in fully automated systems, ensuring their continued leadership in the market.

Within the product type category, horizontal compression baggers are projected to capture 37.6% of the market revenue in 2025, making them the leading product segment. This position has been driven by their superior suitability for high volume, continuous operations, particularly in applications requiring uniform compression and precise bagging.

Horizontal configurations have been favored for their ability to handle a wide range of product sizes and densities while maintaining structural integrity and efficient space utilization.

The segment’s growth has also been supported by its adaptability to various materials and its capability to integrate advanced sealing, cutting, and stacking mechanisms. These characteristics have made horizontal compression baggers an indispensable choice in environments where productivity, reliability, and flexibility are critical.

Segmenting by end use reveals that the food and beverage industry is expected to account for 42.8% of the market revenue in 2025, securing its position as the leading end use sector. This prominence has been shaped by stringent hygiene standards, the need for durable packaging to preserve product quality, and the high volume nature of food production.

Compression baggers have been increasingly deployed to optimize packaging of products such as bulk ingredients, prepared foods, and beverages, ensuring minimal air content and maximized storage efficiency.

The sector’s focus on reducing packaging waste and improving supply chain logistics has further enhanced demand for compression solutions. Moreover, the competitive nature of the food and beverage industry has driven continuous investments in efficient, automated, and reliable packaging equipment, solidifying this segment’s leadership in the market.

Bagging equipment such as compression baggers is used for various materials such as plastic, paper. The compression baggers are used to fill in heavy materials of above 5kg as packaging machinery have a better quality control system that implements new packaging solutions and eliminates major errors that could happen while manual packaging.

Manufacturers are inclined towards compression packaging as it allows the items to be organized and group items together safely. Packaging equipment offers stable, hassle-free packaging performance and is user friendly. The machine is made up of two different modules; the bag sealer and the bag placer.

Compression baggers involve the idea of automatic packaging that possess inbuilt weight set-up options that eliminate any human interactions or continuous supervision during the packaging process.

In the technological era, manufacturers are expecting machinery that performs multitasking capabilities in their offerings to enable the labelling and sealing process.

Packaging machines are in demand in the market as it helps the company meet their demand by increasing the production rate per day which also ensures quality and neat packaging.

Compression baggers can be of different types such as vertical compression bagger, horizontal compression bagger, free flow bagger, and light compression bagger depending upon the application.

To begin with, horizontal baggers is ideal for cellulose, wood shavings, hemp hurd which has made them more popular among packaging manufacturers. Furthermore, vertical baggers are capable enough to pack compressible products in smaller bags which are useful in retail industries, food & beverages, construction, and personal care industries.

This rising growth in various industries for the compression baggers market ensures an increase in demand for the production of convenient consumer packaging.

Moreover, compression baggers specialize in manufacturing packaging products that are small in size such as cartons, sacks, sachets, and flow wraps which are more commonly preferred by the end-users.

Consumers nowadays are demanding smaller pack size for multiple reasons for instance they are more affordable, convenient and easy to carry around. This changing lifestyle preference of consumers is anticipating a steady growth in the compression baggers market.

Compression baggers are creating a huge difference in the packaging industry by being more efficient and reducing the operational cost of the company. Although there are some aspects like customization that can be perfected by manual packaging as automatic machines are set to follow a consistent pattern.

Packaging equipment requires constant and proper maintenance from time to time to retain a smooth flow in the production process. Moreover, the usage of machines in packaging companies is reducing the employment rate affecting the economy of the country to some extent.

Key global players of the Compression Baggers Market are

Key players in the Asia Pacific region of the Compression Baggers Market are

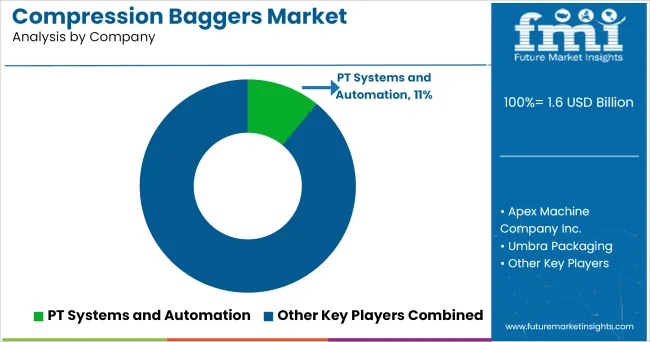

The global compression baggers market is estimated to be valued at USD 1.6 billion in 2025.

The market size for the compression baggers market is projected to reach USD 2.9 billion by 2035.

The compression baggers market is expected to grow at a 6.0% CAGR between 2025 and 2035.

The key product types in compression baggers market are automatic and semi-automatic.

In terms of product type, horizontal compression bagger segment to command 37.6% share in the compression baggers market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Insights for Compression Baggers Providers

Compression Testers Market Size and Share Forecast Outlook 2025 to 2035

Compression Product Market Size and Share Forecast Outlook 2025 to 2035

Compression Garments Market Size and Share Forecast Outlook 2025 to 2035

Compression Testing Machines Market Size and Share Forecast Outlook 2025 to 2035

Compression Garments and Stockings Market Analysis - Size, Share, and Forecast 2025 to 2035

Compression Gas Spring Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Compression Veterinary Bandages Market Trends – Growth & Forecast 2025 to 2035

Industry Share Analysis for Compression Packing Providers

Compression Therapy Market Insights – Growth & Forecast 2024-2034

Compression Bags Market

Decompression Toys Market Growth - Trends & Forecast 2025 to 2035

Box Compression Tester Market Size and Share Forecast Outlook 2025 to 2035

Radial Compression Devices Market Growth - Trends & Forecast 2025 to 2035

Distal Compression Plates Market

Artery Compression Devices Market

Colon Decompression Kits Market

Abdominal Compression Garments Market Size and Share Forecast Outlook 2025 to 2035

India Static Compression Therapy Market Report – Trends & Forecast 2016-2026

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA