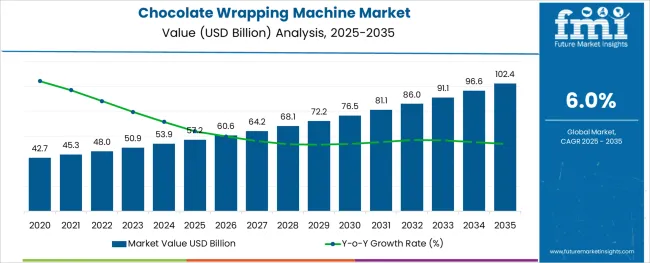

The Chocolate Wrapping Machine Market is estimated to be valued at USD 57.2 billion in 2025 and is projected to reach USD 102.4 billion by 2035, registering a compound annual growth rate (CAGR) of 6.0% over the forecast period.

The chocolate wrapping machine market is witnessing steady momentum, driven by the increasing scale of chocolate production, rapid packaging line automation, and the need for consistent, contamination-free wrapping. As global chocolate consumption rises, manufacturers are investing in high-speed wrapping systems that enable precise, tamper-evident, and attractive packaging.

The shift toward flexible packaging formats and foil-based barrier materials is further accelerating machine innovation, with improved sealing, cutting, and throughput capabilities. Regulatory emphasis on food safety and labeling, along with demand for visually distinct branding, is prompting companies to adopt machines that support advanced printing and material compatibility.

The market is also being influenced by energy-efficient motors and modular machines capable of accommodating various pack sizes and product forms. Looking ahead, increased digital integration, such as smart diagnostics and production analytics, is expected to shape the evolution of chocolate wrapping systems for both large-scale and niche confectionery operations.

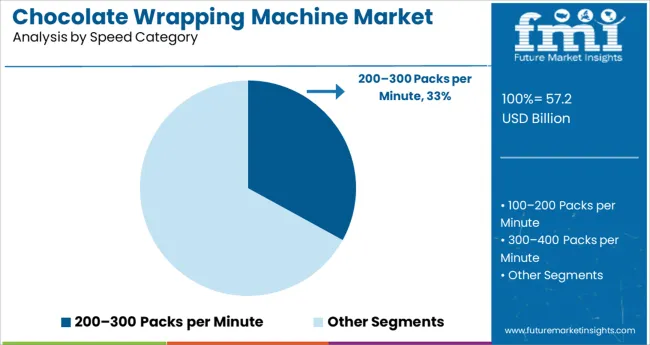

The market is segmented by Speed Category and Application and region. By Speed Category, the market is divided into 200-300 Packs per Minute, 100–200 Packs per Minute, 300-400 Packs per Minute, and More than 400 Packs per Minute.

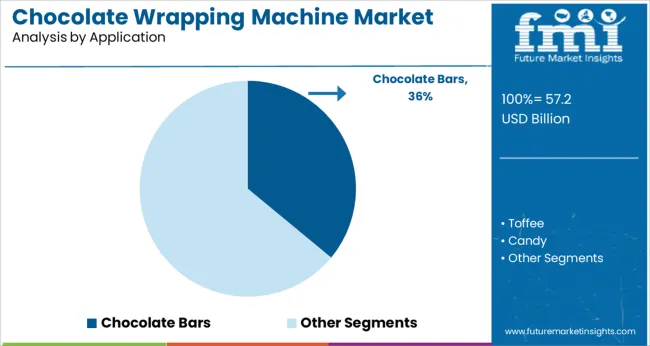

In terms of Application, the market is classified into Chocolate Bars, Toffee, Candy, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The 200-300 packs per minute speed category is anticipated to hold a 33.0% share of the chocolate wrapping machine market in 2025. This segment's leadership is driven by its optimal balance between speed and mechanical reliability, making it suitable for mid- to large-scale chocolate manufacturing operations. Machines in this speed range offer higher efficiency while maintaining packaging precision and minimal product waste, which is essential for premium chocolate items and brand-sensitive production lines.

Manufacturers have increasingly adopted this speed range for its capability to reduce downtime and support integration with automated feeding and quality control systems. The moderate capital and maintenance costs associated with this speed class also enhance its appeal among regional producers and contract packagers aiming to scale operations without compromising on packaging standards.

Its compatibility with foil, paper, and laminate wraps further reinforces its adaptability across a range of chocolate product formats.

The chocolate bars segment is projected to contribute 36.0% of the total market share in 2025, making it the dominant application in the chocolate wrapping machine market. This segment’s prominence is attributed to the consistent global demand for bar-shaped chocolates, which require uniform and protective wrapping to maintain texture, shape, and shelf life.

Chocolate bar wrapping machines are designed to deliver precise sealing, high throughput, and adaptability to multiple bar sizes, supporting both large-scale confectionery manufacturers and private label producers. The integration of heat sealing, flow wrapping, and gusseting technologies in bar-focused machines ensures secure packaging and enhanced visual presentation.

Demand for individual bar packaging in multipacks, retail units, and impulse purchase displays has further contributed to the segment’s expansion. As producers innovate with filled, layered, or textured bars, wrapping machines capable of gentle handling and accurate wrap alignment are seeing heightened deployment in production facilities globally.

Globally, the chocolate production has increased many folds since last decade in most of the countries, prominently in Europe. The changing consumer preferences towards the specialty chocolates has fuelled the demand for chocolate and confectionery industry. The increase in the consumption of the chocolates and confectionery food items has resulted in the escalated demand for the chocolate flow wrapping machines market.

The chocolate producers are spending high amounts of money to automate the overall process of the chocolate production to increase their profitability margins. The chocolate flow wrapping machines automate the packaging process of the chocolate and confectionery items. The machines offer a variety of pack design features according to the specific demand of the chocolate manufacturers.

It offers convenience to flow wrap any type of packaging material such as paper or cardboard, aluminum, plastics, and others. The machines provide ideal packaging solution for the flow wrap packaging of the chocolate and confectionery items along with the consistent packaging for every item.

Also, the chocolate flow wrapping machines are incorporated with different equipment to produce a variety of packaging sizes. The machine eliminates the challenges faced during the production and packaging process of the chocolates and confectionery items.

Globally, the rise in demand for the chocolates and confectionery products has fuelled the demand for the chocolate wrapping machines market. The wrap-type packaging is widely used packaging technique for the packaging of the chocolates across the globe.

The changing consumer preferences and rise in disposable income have resulted in the rise in consumption of the chocolates and growth of the chocolate producing companies which in turn spend high on the automation process to increase profitability margins.

The alternative packaging solution may hamper the growth of the chocolate wrapping machines market in the near future. Also, the change in technology may result in the decline in the growth of the market.

The recent trends observed in the chocolate wrapping machines market is the customization of the machines according to the packaging needs of the chocolate manufacturers. The chocolate manufacturers are aiming cheap machinery with high production outputs.

Geographically, the global Chocolate Wrapping Machine market is segmented across following regions- North America, Asia-Pacific Excluding Japan, Japan, Eastern Europe, Western Europe, Latin America, Middle East and Africa. Europe dominates the chocolate flow wrapping machines market due to the high penetration of the chocolate producers in the region.

The packaging trend in this region is also shifting from the manual processes to the modern technologies. The North America is expected to be the second largest market in the chocolate wrapping machines market due to the high consumption of chocolate and high number of chocolate producers in the region.

Manufacturers in North America also export chocolates and confectionery to the other parts of the world including Asia-Pacific, MEA, and Japan which ultimately drives the market of chocolate wrapping machine. The manufacturing process of the chocolates in this region is facilitated by the highly automated chocolate wrapping machinery.

The trend for plant automation in the Asia Pacific and MEA region is emerging and is expected to grow several folds in the next few years. The Japan and Latin America region also offer untapped growth potential for the chocolate wrapping machines market in near future.

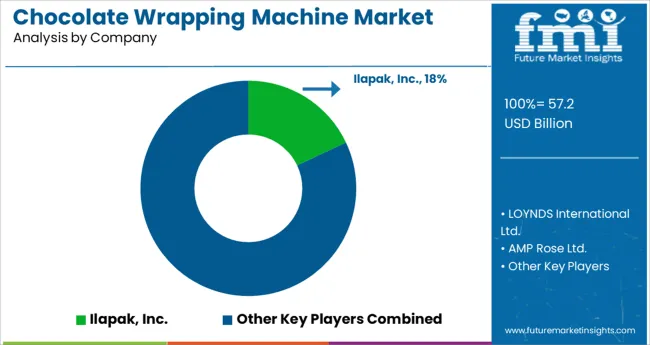

Some of the key players in the global chocolate wrapping machine market are Ilapak, Inc., LOYNDS International Ltd., AMP Rose Ltd., LOESHCHPACK PIPENBROCK Group, MAKREV Packaging, Taizhou Funengda Industry Co., Ltd., TENCHI SANGYO & TENCHI KIKAI Co., Ltd.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global chocolate wrapping machine market is estimated to be valued at USD 57.2 billion in 2025.

It is projected to reach USD 102.4 billion by 2035.

The market is expected to grow at a 6.0% CAGR between 2025 and 2035.

The key product types are 200–300 packs per minute, 100–200 packs per minute, 300–400 packs per minute and more than 400 packs per minute.

chocolate bars segment is expected to dominate with a 36.0% industry share in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Chocolate Powdered Drinks Market Forecast and Outlook 2025 to 2035

Chocolate Bar Packaging Market Size and Share Forecast Outlook 2025 to 2035

Chocolate Market Size and Share Forecast Outlook 2025 to 2035

Chocolate Flavoring Compounds Market Size and Share Forecast Outlook 2025 to 2035

Chocolate Couverture Market Size, Growth, and Forecast for 2025 to 2035

Chocolate Processing Equipment Market Size, Growth, and Forecast 2025 to 2035

Chocolate Flavors Market Analysis by Product Type, and Application Through 2035

Chocolate Confectionery Market Analysis by Product, Type, Distribution Channel, and Region Through 2035

Chocolate Inclusions and Decorations Market Analysis by Type, End Use, and Region Through 2035

Industry Share Analysis for Chocolate Bar Packaging Companies

Chocolate Syrup Market

Chocolate Wrapping Films Market from 2025 to 2035

Non-Chocolate Candy Market

Vegan Chocolate Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Premium Chocolate Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Compound Chocolate Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Sugarless Chocolate Market

Industrial Chocolate Market Analysis by Product, Application, Type, and Region through 2035

Analysis and Growth Projections for Low-calorie Chocolate Business

Sugar-Free White Chocolate Market Trends - Demand & Growth 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA