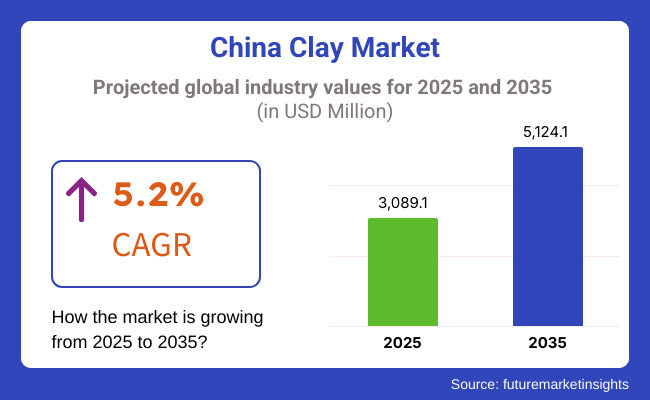

The global China clay market is projected to experience steady growth between 2025 and 2035, driven by rising demand from the ceramics, paper, rubber, and construction industries. The market is expected to reach USD 3,089.1 million in 2025 and expand to USD 5,124.1 million by 2035, reflecting a compound annual growth rate (CAGR) of 5.2% during the forecast period.

Kaolin, often referred to as China clay, is a soft white mineral which finds application in various industrial fields including ceramics, coatings, paints, and personal care products. The paper industry is looking for high-quality kaolin which is being used to increase print quality, the ceramics sector is gaining momentum, as well as, the use in high-performance polymers and adhesives are among the major driving forces of the growth of the market.

Moreover, the evolution of technology in processing, an increase in funding for responsible mining, and the use of China clay in niche segments like medicines and cosmetics are the major factors that will steer the market in the future. China clay demand is spurred by infrastructure project expansions, growth in the packaging materials sector, and the production of high-performance composites.

The rising consumption of kaolin-based ceramics, increasing adoption in pharmaceutical formulations, and demand for high-quality paper coatings are driving market expansion. Additionally, the growth of eco-friendly paints, sustainable packaging materials, and advanced polymer composites is expected to create new opportunities for China clay applications.

Explore FMI!

Book a free demo

North America continues to be the most prominent market for kaolin, as the paper, ceramics, and rubber industries drive the high demand. The USA and Canada are experiencing the largest share of the growth of kaolin-based coatings in the packaging sector, a boom of construction projects for ceramic tiles, and wider use of kaolin in cosmetics and medicines.

The change from non-recyclable to recyclable packaging materials is bringing along the use of kaolin-coated papers and biodegradable fillers. Besides, the technological revolution in mining techniques, alongside with the binding of environmental regulations, is edging manufacturers toward the production of low-impact, high-purity kaolin products.

The European China clay market is trending upward with strong demand by the ceramics, paints, and construction industries. Leading countries like Germany, France, and Italy produce the most ceramic tiles and supply high-performance coatings driving the usage of high-quality kaolin which enhances both hardness and beauty.

The European Union's agenda for sustainability and the increasing funding in green buildings are the avenues for kaolin-based eco-friendly coatings and insulation materials. What's more, the rise in the number of personal care products & cosmetics with natural mineral ingredients is facilitating the state of the market in the European region.

The Asia-Pacific region is at the forefront of China clay-making products, surging on the fast industrial revolution, surpassing ceramic production, and the rise of paper and rubber industries. Nations like China, India, Japan, and South Korea also are demanding more high-purity kaolin for industrial applications in the fields of paints, adhesives, and composites.

The dominance of ceramic manufacturing and infrastructure in China is pushing kaolin consumption considerably upward. The use of kaolin in the construction industry, paper production, and polymer additives is the other success story of India. On the other hand, Japan and South Korea are excelling in high-end usage in advanced coatings and specialty chemicals, respectively.

The Middle East & Africa (MEA) region is getting popular as a destination for kaolin, especially construction, ceramics, and petrochemical applications. Saudi Arabia, the UAE, and South Africa, among others, are extending their infrastructure projects, which will ultimately heighten the demand for high-quality ceramic tiles, coatings, and insulation materials.

In addition, the expansion of the petrochemical industry has been achieved due to the increased acceptance of kaolin-based catalysts which also contributes to the market growth. The demand for green building materials and adopting advanced polymer applications paves the way further for the development of the market in the MEA territories.

Challenges

Environmental Concerns and Regulatory Compliance in Mining

The environmental concerns of kaolin mining and processing are one of the main challenges facing the China clay industry. The process of extracting kaolin degrades the land, causes water pollution, and consumes large amounts of energy during processing, thus raising the issues of sustainability and regulatory adherence.

Governments and regulatory authorities like the Environmental Protection Agency (EPA) in North America and REACH in Europe have enacted stringent mining regulations, helping achieve the transition to green and circular economy. For example, these require zero-waste extraction and landfill measures, as well as land restoration initiatives after mining is completed. Environmental standards compliance leads to a rise in production costs, which, in turn, makes it harder for small and medium-sized businesses to survive the competition with large ones.

For this reason, firms are turning to new processing technologies, water recycling systems, and adoption of eco-friendly mining methodologies to minimize their carbon and ecological footprint, delivering quality products to their customers.

Impact of External Supply Chain Disruptions on the Kaolin Industry: Challenges and Strategic Responses

The kaolin industry is very vulnerable to the externally sourced raw material supply chains and any disruptive factors from the externally sourced raw material supply chains like fluctuations in mining costs, transportation expenses, and geopolitical factors can have a serious impact on the industry market condition. The increasing costs of energy, labour, and shipping are also playing a significant role in affecting profit margins for China clay producers.

On top of this, the supply chain disruptions that occurred during the pandemic because of lockdowns, trade restrictions, and geopolitical conflicts resulted in delays in the procurement of raw materials and the export of finished goods. To decrease these challenges, companies are emphasizing the focusing on setting up regionalized supply chains, entering into strategic partnerships, and implementing different sourcing strategies to guarantee the constant availability of products and control over expenses.

Opportunities

Advancements in High-Purity and Specialty Kaolin Products

The specialty applications of high-purity kaolin are generating new market opportunities. Premium quality calcined kaolin, metakaolin, and nano-kaolin mixtures are being increasingly used in high-performance ceramics, advanced composites, and catalytic applications.

Producers have started to target the improvements, especially in mechanical strength, thermal resistance, and optical properties of kaolin, so that they can respond to the demanding needs in aerospace, automotive, and energy storage systems. Moreover, the introduction of high-reactivity metakaolin in cement and concrete mixtures is predicted to substantially increase the share of sustainable construction materials.

Growing Demand in Cosmetics, Pharmaceuticals, and Personal Care

The tendency of using kaolin in personal care, pharmaceuticals, and cosmetic applications is opening doors for growth to many brands. China clay is the preferred material for skincare products, face masks, and mineral-based cosmetics due to its features being absorbent, detoxifying, and non-toxic.

The fastest-growing sector of natural and organic cosmetic formulations, combined with consumers being increasingly informed about skin-friendly and eco-friendly materials, supports the demand for high-quality kaolin-based products. Also, the pharmaceutical industry has been applying kaolin to prepare controlled drug delivery systems and excipient formulations, which contributes to its scope even more.

From 2020 to 2024, the operation of the China clay market was stable, with the rise in demand in the ceramic, paper production, paints & coatings, and rubber industries being the driving force. Kaolin (China clay), which has high brightness, smaller particle size, and superb dispensability, is the chief and major raw material in the ceramics and porcelain sector, the paper coating, and also the specialty applications in pharmaceuticals and cosmetics.

The urbanization, and the construction sector's expanding, along with the growing demand for high-quality ceramic tiles and sanitary ware are the aspects which the market owes its development to. On the other hand, the major problems facing the market are the environmental issues that are associated with mining activities, the regulatory measures, and the supply chain disturbances that have had a negative impact on market stability.

The period between 2025 and 2035 will be a period of major changes in the China clay market with such innovations as AI quality control, eco-friendly extraction processes, and the growing demand for high-purity kaolin in advanced applications. The development of lightweight nanocomposite materials, AI-augmented material sorting, and bio-based coatings will be the drivers for future market changes. Furthermore, the emergence of smart ceramic applications, the increase in high-opacity fillers demand in paints, and the advancements of ultrafine kaolin for electronics and high-end paper will be the factors that will reshape the industry.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 |

|---|---|

| Ceramic & Porcelain Demand | Expansion in tile manufacturing, sanitary ware, and high-quality ceramic production drove kaolin demand. |

| Paper & Packaging Industry Growth | Kaolin was widely used in paper coatings for improved brightness, opacity, and smoothness. |

| Advancements in Paints & Coatings | Kaolin-based coatings improved texture, whiteness, and anti-corrosion properties in paints. |

| Rubber & Plastics Industry Expansion | Use of kaolin as a filler in rubber and plastic composites increased due to rising industrialization. |

| Sustainability & Eco-Friendly Mining | Stricter mining regulations and sustainability concerns led to investments in greener extraction technologies. |

| High-Purity Kaolin for Advanced Applications | Increasing demand in pharmaceuticals, cosmetics, and high-end ceramic applications. |

| Market Growth Drivers | Growth fuelled by rising urbanization, ceramic industry expansion, and demand for high-quality industrial fillers. |

| Market Shift | 2025 to 2035 |

|---|---|

| Ceramic & Porcelain Demand | AI-assisted ceramic production, nanostructured China clay for wear-resistant surfaces, and graphene-kaolin composites redefine performance. |

| Paper & Packaging Industry Growth | Rise of bio-based and sustainable packaging reduces kaolin demand, but ultra-fine kaolin in specialty paper markets expands. |

| Advancements in Paints & Coatings | Nano-kaolin-based hydrophobic coatings, AI-optimized pigment blending, and lightweight high-opacity kaolin applications in industrial coatings. |

| Rubber & Plastics Industry Expansion | Development of AI-driven polymer-kaolin composites for lightweight, fire-resistant, and recyclable materials. |

| Sustainability & Eco-Friendly Mining | Carbon-neutral kaolin production, AI-assisted precision mining, and block chain-enabled supply chain tracking improve efficiency. |

| High-Purity Kaolin for Advanced Applications | Expansion of ultra-pure kaolin in battery materials, semiconductor polishing, and biodegradable medical coatings. |

| Market Growth Drivers | Market expansion driven by smart materials, AI-integrated supply chain optimization, and sustainable high-purity kaolin solutions. |

Impact of External Supply Chain Disruptions on the Kaolin Industry: Challenges and Strategic Responses USA china clay sector is undergoing constant progress due to the high requirement from sectors like ceramics and paper as well as paints and coatings. The demand for high-quality kaolin in ceramic tiles and sanitary ware is bolstered by the progress of the construction industry, especially in residential and commercial flooring applications.

The American paper industry which is moving towards digitalization needs kaolin in coated paper mills for the production of magazines and packaging materials besides specialty papers. Moreover, the manufacturing of such car and aircraft is introducing more kaolin containing coatings and polymer fillers in the processes, which are durable and have a good finish.

The growth of met kaolin in green concrete applications is also increasing with the sustainability programs and LEED-certified building projects. Kaolin’s emerging role in the treatment of medicines and its use in cosmetics are also responsible for the market development. Expansion of the Construction Sector & Ceramic Tile Demand: Increased use of kaolin in sanitary ware and flooring materials.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 5.3% |

The China Clay market in the United Kingdom is currently developing at an average rate that is being sustained by the correspondingly increasing sales of ceramic exports, and the increased application of kaolin in pharmaceuticals and the up surging need for environmental-friendly paints. UK has the distinction of being the second largest producer in Europe for kaolin particularly in areas such as Cornwall. This factantiates the significance of their role as a key supplier of kaolin in both ceramics and paper industries in Europe.

As the UK is striving to be more sustainable and to reduce its carbon footprint, low-VOC, kaolin-based paints are becoming increasingly popular in construction and home renovation projects. In addition, the trend towards more environmental-friendly packaging is pushing the utilization of kaolin in the case of biodegradable paper products.

The demand for kaolin is also spurred by the rise in the cosmetics and pharmaceutical sectors, as kaolin is widely used in personal care formulations, oral medicines, and skincare products. Strong Kaolin Production Base in Cornwall Supporting Domestic & Export Markets: Increased supply for ceramics and paper industries.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 5.0% |

The European Union China clay market is proliferating because of the continuous growth in the consumption of the ceramics, paper, and plastic industries. Environmental laws promoting the use of sustainable materials are also driving the transition towards a greener economy. The top consumers of kaolin-based ceramic materials are Germany, France, and Italy; they use them to make various construction, home décor, and luxury tableware items.

The EU's program to cut down plastic waste has led to the increased consumption of kaolin as a filler material in biodegradable plastics and packages. The renewable energy projects, which include the wind turbine production, are also the cause of the request for kaolin-based composites and coatings.

Though still in digitization, the European paper industry needs high-quality kaolin for coated papers, packaging boards, and specialty printing applications. In addition, metakaolin developments have resulted in more durable concrete and improved thermal insulation in green buildings.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 5.2% |

Japan's China clay sector is experiencing a moderate, growing trend under the influence of the rising demand for advanced ceramics, electronics, and cosmetics applications. The country’s ceramics industry, which is the most developed globally, produces diverse industrial and artistic ceramics and uses kaolin exclusively.

Electrical and semiconductor sectors are also referenced in paper towards the further development of this market as kaolin is used in ceramic substrates and thermal insulation coatings that circuit boards and high-temperature electronics operate. Besides, the use of kaolin in facial masks, powders, and cosmetics has surged as a consequence of the acquisition of high-end cosmetic products which is why the increase is noted.

The increase in the ratio of the elderly and the inventions in medical technologies have propelled the demand of kaolin in the markets dealing with the pharmaceutical and dental sector, especially oral drug formulations and dental ceramics. High Demand for Advanced Ceramics in Electronics & Industrial Applications: Increased use of kaolin in high-temperature ceramic materials.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 5.0% |

As has been observed on the market for China clay in South Korea, electric devices, personal care products, and eco-friendly buildings that are not made using concrete have been the major drivers behind the growth of the market. Strong semiconductor industry is the demand driver of kaolin in the ceramic substrates and microelectronics sectors.

The booming beauty and skincare market of South Korea has also been the push factor of kaolin in face masks, cleansers, and makeup formulations. The green construction materials trend is generally raising the metakaolin needs in applications such as high-strength concrete.

Owing to the growing consumer interest in green packaging, the use of kaolin in such paper and plastic alternatives is also on the rise. Besides, the application of high-quality coatings not only in the automotive but also in the industrial sector has been the cause of the boost in the kaolin-based paint and coating market.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 5.1% |

Water-washed China clay is the main product in the market as it has the highest purity, tiny particle sizes, and is the brightest making it a suitable material for ceramics, paints, coatings, and fiberglass. The process is done through hydro-separation, where iron and other mineral contaminants are removed, allowing for the production of high-quality kaolin for industrial applications.

Ceramics and sanitary ware are the top sectors in China that use water-washed China clay in abundance. It is because of its advantages such as strong whiteness, plasticity, and firing properties, that the material is a key component in making tiles, porcelain, and high-end ceramic products.

Moreover, the paper and coatings sectors stand for water-washed clay because this unique material improves the surface gloss and printability of coated paper and paint formulations by providing smoothness, and opacity enhancement, and dispersion properties. Water-washed kaolin, which is used in high-performance industrial fillers, has the advantage of being the most significant segment in the clay industry.

Calcined China clay is registering significant sales growth, especially in the supplies of paints and coatings, plastics, and rubber where brightness, opacity and thermal stability are major requirements. The process involves heating at elevated temperatures which makes kaolin whiter, more resistant to the electrical current, and more efficient in scattering light, which is why it is a good substitute for titanium dioxide (TiO₂) in industrial coatings.

The paints and coatings sector is the largest market for calcined kaolin, as it enhances rheology, scrub resistance, and pigment extension, thus making the coatings more durable and cost-effective. Moreover, plastic and rubber makers are utilizing calcined kaolin as a strengthening additive, which will consequently increase UV protection, lifespan and dimensional stability of flexible products. The search for eco-friendly and lightweight material solutions in turn drives the growth of calcined China clay as a crucial additive.

The ceramics and sanitary ware segment is the largest end-user of China clay, thanks to the rapid growth of construction activity, urbanization, and increased demand for superior ceramic products. China clay is essential for the production of tiles, sanitary ware, porcelain, and tableware, because it offers better plasticity, workability, and whiteness, which are critical for the manufacture of high-quality ceramics.

With the quick infrastructure build-up in developing countries, manufacturers are now focusing on the installation of modern techniques that will ensure the purity, brightness, and mechanical strength of kaolin are improved, thus, they can make attractive and durable products in ceramic applications. Furthermore, the sanitary ware area is witnessing remarkable growth, particularly with more water-efficient and designer bathroom fixtures becoming popular, an absolute requirement for the kaolin in ceramic formulations hence high-grade kaolin.

The fiberglass sector is currently experiencing increased usage of China clay by the manufacturers who are in search of high-end mineral fillers for thermal stability, durability, and reinforcement. Among these enhancements, China clay is a functional additive and is used in fiberglass production for its superior binding properties and thus, it has a very low value of shrinkage. Composite materials, insulation panels, and reinforced plastics are products that often contain this ingredient.

Fiberglass is primarily sought after in the automotive and construction industries because manufacturers are looking for lightweight and durable materials for vehicle parts, building facades, and energy-efficient houses. Along with the development of the wind energy sector, fiberglass is now made with stronger China clay in wind turbine blades, extending the service life and enhancing the mechanical properties. As renewable energy and advanced composite materials become more popular among the public, the need for high-quality China clay in the production of fiberglass will also rise.

The global China clay (kaolin) market currently shows a growth trend due to the rising demand from the paper, ceramics, rubber, paint, and coatings industries. China clay is recognized for its high whiteness, fine particles, and excellent plasticity that it is a vital component in the making of ceramics, paper coating, and industrial fillers.

The sector is affected by technological developments in kaolin processing along with the increasing use of high-purity kaolin in particular applications and environmental pressure leading to sustainable mining operations. Major firms predominantly deal with the high-performance calcined kaolin, metakaolin, and the specific kaolin formulations, serving the industries such as construction, pharmaceuticals, and plastics.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Imerys S.A. | 10-12% |

| BASF SE | 9-11% |

| KaMin LLC / CADAM S.A. | 8-10% |

| Thiele Kaolin Company | 6-8% |

| Ashapura Group | 5-7% |

| Other Companies (combined) | 51-61% |

| Company Name | Key Offerings/Activities |

|---|---|

| Imerys S.A. | A global leader in kaolin-based solutions, offering high-brightness, calcined, and hydrous kaolin for ceramics, paper, and coatings. |

| BASF SE | Develops high-performance kaolin for coatings, rubber, plastics, and pharmaceuticals, integrating advanced processing technologies. |

| KaMin LLC / CADAM S.A. | Specializes in ultra-fine, calcined, and high-purity kaolin for industrial applications, ensuring improved dispersion and performance. |

| Thiele Kaolin Company | Provides customized kaolin formulations, focusing on ceramic, paper, and high-performance polymer applications. |

| Ashapura Group | Offers low-cost, high-quality China clay mining solutions, supplying industries such as ceramics, paints, and construction materials. |

Imerys S.A.

Imerys is a frontier in the field of kaolin-based minerals, providing China clay solutions with high performance for ceramics, paper, and coatings. The products of the company which are calcined kaolin give the paint, plastics, and rubber industry good opacity, brightness, and durability. Deutsche Imerys is a leading player in the market of sustainable kaolin mining and advanced processing technologies, and it also ensures the eco-friendly and high-purity China clay production.

BASF SE

BASF focuses on the manufacture of kaolin and its integration into coatings, adhesives, and pharmaceuticals through advanced processing techniques. The company has a range of Engelhard kaolin that provides high brightness, rheology control, and chemical resistance; therefore, it is ideal for industrial use. Green processing of kaolin is the new focus of BASF, which aims at sustainable resource extraction and minimal waste generation.

KaMin LLC / CADAM S.A.

KaMin LLC along with its subsidiary CADAM S.A. is a primary supplier of kaolin specialty products which include both calcined and hydrous kaolin with even better dispersion. The company offers the Hyperlite and Ultrex series with increased opacity, low abrasion, and thermal resistance which are appropriate for the paper, paints, and polymer industries. KaMin has been focusing on the investment in tailored kaolin solutions that will increase the performance in high-end industrial applications.

Thiele Kaolin Company

Thiele Kaolin Company specializes in the supply of customized formulated kaolin products that meet high brightness and are low abrasion for the aforementioned industries. Kaowhite and K-Tec series of the company feature excellent quality of dispersion, control of particle size, and enhanced opacity which make them suitable for industrial coatings and engineering materials. Thiele is increasing its technical service support and providing applications-specific kaolin grades to give adapted solutions to more sectors.

Ashapura Group

Ashapura Group is a high-volume producer of competitively priced solutions of China clay, which delivers low-cost, high-purity kaolin for ceramics, paints, and building materials. The company is concentrating on environmentally friendly mining and large-scale production efficiency, thus consistent supply for high-volume industries is ensured. Ashapura is nurturing its research funding for new beneficiation technologies with the goal of kaolin improved refining and enhanced end-use.

The global China clay market is projected to reach USD 3,089.1 million by the end of 2025.

The market is anticipated to grow at a CAGR of 5.2% over the forecast period.

By 2035, the China clay market is expected to reach USD 5,124.1 million.

The ceramics and sanitary wares segment is expected to dominate due to the extensive use of China clay in porcelain, tiles, and sanitary ware production, driven by increasing demand in the construction and interior design sectors.

Key players in the China clay market include Imerys S.A., KaMin LLC, Ashapura Group, EICL Limited, and Quarzwerke GmbH.

Hydrous, Calcined, Delaminated, Surface-Modified

Paper & Packaging, Ceramics & Refractories, Paints & Coatings, Rubber & Plastics, Cosmetics & Personal Care, Pharmaceuticals, Agriculture & Fertilizers

White, Pink, Yellow/Red

North America, Latin America, Western Europe, Eastern Europe, South Asia & Pacific, East Asia, Middle East & Africa

Diamond Wire Market Size & Outlook 2025 to 2035

Thioesters Market Growth & Trends 2025 to 2035

The Self-Healing Materials Market is segmented by product, technology, and application from 2025 to 2035.

Polyurethane Foam Market Size & Trends 2025 to 2035

Polyurethane Adhesives Market Trends 2025 to 2035

Heat Resistant Glass Market Size & Trends 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.