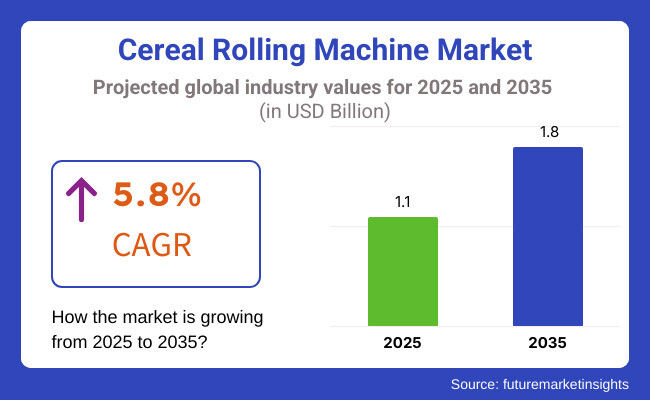

The global cereal rolling machine market is estimated to account for USD 1.1 billion in 2025. It is anticipated to grow at a CAGR of 5.8% during the assessment period and reach a value of USD 1.8 billion by 2035.

Industry Outlook

From 2025 to 2035, the cereal rolling machine market is expected to grow substantially, fueled by the growing worldwide demand for ready-to-eat breakfast cereals. This expansion is primarily attributed to consumers' hectic lifestyles and a growing need for easy meals. Food processing equipment advances are anticipated to enhance production efficiency and quality, further propelling market expansion.

Additionally, additional development of retail infrastructures, particularly in emerging economies, is also poised to facilitate greater market penetration. However, these kinds of manufacturers would be likely to face problems like price fluctuations of raw materials and meeting rigorous food safety regulations. Otherwise, the outlook for the industry is relatively positive, and there are a lot of prospects for innovation and expansion of the market.

Explore FMI!

Book a free demo

| 2020 to 2024 | 2025 to 2035 |

|---|---|

| Increased consumption of ready-to-eat (RTE) cereals due to changing lifestyles | Further demand growth due to health-conscious consumers, automation, and technological innovation |

| Preference for convenience foods amid urbanization & busy work schedules | Shift towards healthier, organic, and fortified cereals to meet wellness trends |

| The initial phase of automation and innovation in cereal processing | Advanced AI-driven automation, energy-efficient machines, and smart processing systems |

| Supply chain disruptions due to COVID-19, high raw material costs | Rising regulatory requirements, sustainability concerns, and fluctuating raw material prices |

| Strong market in North America and Europe, emerging demand in Asia-Pacific | Rapid expansion in Asia-Pacific and Latin America due to growing middle-class populations |

| Dominated by major players like Nestlé, Kellogg’s, and PepsiCo | Increased competition with new entrants, product diversification, and regional expansions |

Increased Demand for Whole-Grain Cereals and High-Fiber Ingredients

As per FMI analysis, consumers are getting increasingly health- and wellness-conscious, leading to the demand for whole-grain cereals, high-fiber ingredients, and natural sweeteners. Cereal rolling machine producers are addressing this challenge by designing advanced equipment that is capable of efficiently processing organic, fortified, and gluten-free grains. With increasingly ingredient-conscious consumers, businesses are focusing on clean-label processing that does not include artificial additives but preserves nutrients.

The growing demand for convenience and ready-to-eat (RTE) food is fueling market growth

Urban lifestyles and urbanization are leading consumers to seek out cereals that entail less prep time. Cereal rolling machine manufacturers are adopting automation and artificial intelligence-based technology to enhance production speed and consistency. These developments enable food companies to address the increasing demand for on-the-go breakfast options, especially in urban cities.

Sustainability issues are driving the purchase decisions with consumers looking for brands that practice green and energy-efficient production processes. Cereal companies are spending money on equipment that minimizes energy use, saves waste, and uses recyclable packaging material. The need for carbon-free production is also forcing machine companies to go out of the box when it comes to green technology according to world agendas of sustainability.

Personalization is coming into focus as a top trend with consumers searching for customized nutrition based on nutritional needs and personal taste. A trend toward machine flexibility is prevailing in the market, allowing processors to create an entire line of cereal items that go from high-protein to low-sugar. Equipment relying on machine learning supports the small-batch process, offering specialty niches for unique tastes, textures, and nutritional values.

Direct-to-consumer (DTC) and online channels are transforming the cereal industry. As more consumers purchase cereals online, brands require efficient and scalable manufacturing processes to match demand. High-tech cereal rolling machines are assisting businesses in streamlining operations, ensuring quality control, and providing quick delivery. Subscription-based cereal services are also driving investment in high-capacity and multi-functional rolling machines.

These megatrends confirm that the market for cereal rolling machines will continue to evolve on the basis of health-driven consumers, advancements in technology, and sustainable measures. The players adopting these changes will get an advantage over competitors in the highly burgeoning business.

Based on product type, the market is divided into hot cereal, ready-to-eat cereal, flaked cereals, puffed cereals, shredded cereals, and others. Cereal rolling machines find extensive applications in the manufacturing of Hot Cereal, Ready-to-Eat (RTE) Cereal, Flaked Cereals, Puffed Cereals, and Shredded Cereals as they help increase efficiency, consistency, and product quality. Increasing demand for RTE cereals, as customers increasingly opt for easy breakfast alternatives, is leading manufacturers to make significant investments in high-speed rolling machines that have the capability to grind grains to different textures.

Flaked cereals like cornflakes need exact rolling to create the thin, uniform sheets necessary for maximum crispness and texture. Puffed cereals, on the other hand, that are subjected to high-pressure rolling prior to their puffing rely on specific machines to maintain the integrity of structure and lightness.

Based on end-use, the market is divided into roots, grain, mixtures for dairy substitutes, the milling industry, agricultural, and balanced feed mix. Cereal rolling machines are widely applied in root, grain, dairy substitute mixture processing, milling industry, agriculture, and compound feed mixes because they can process raw materials into high-quality, uniform products.

In the milling sector, cereal rolling machines are very important in flattening and grinding grains such as wheat, corn, and barley to yield flour, semolina, and meal for human and industrial use. The farming industry depends on cereal rolling machines to mill animal feed, producing the best particle sizes that maximize digestibility and nutrient uptake in livestock.

The growing need for dairy alternatives has also boosted the application of rolling machines in processing oat, almond, and rice-based blends, which are used as main ingredients for plant-based milk substitutes. The machines facilitate the grinding of grains and roots into fine, consistent flakes, allowing for improved extraction of natural starches and proteins. In the manufacture of balanced feed mixes, cereal rolling machines assist in homogenizing feed ingredients, and maximizing nutritional content for livestock and poultry.

Based on automation, the market is divided into automatic, manual, and semi-automatic. Automatic, Manual, and Semi-Automatic cereal rolling machines find extensive applications in different industries owing to their suitability for different scales of production, efficiency requirements, and budgets.

Automatic cereal rolling machines are immensely sought after for large-scale industrial production, wherein high-speed processing, precise control, and least human intervention are essential. Such machines provide quality consistency, uniformity, and efficiency, thus being best suited for mass-scale production of ready-to-eat cereals, flaked cereals, and puffed cereals.

The USA is experiencing increasing demand for cereal rolling machines because of the increased popularity of ready-to-eat and hot cereals. Consumers are looking for convenience and nutrition, and hence manufacturers are investing in sophisticated rolling machines that increase the efficiency and consistency of the product. The growth of supermarkets and hypermarkets, as well as growing innovations in cereal formulations, also drives market growth.

With the transition to processed and healthy breakfast cereals gaining pace in India, demand for cereal rolling machines is being driven. Urbanization, changing lifestyles, and rising disposable incomes are influencing consumption. The industry is also gaining from the rising health awareness levels, which are inducing manufacturers to switch over to effective rolling technology in making high-fiber, multigrain, and fortified breakfast cereals.

Germany is experiencing a shift from traditional breakfast options to healthier alternatives, leading to increased demand for cereal rolling machines. Consumers are opting for low-carb, high-protein, and organic cereals, pushing manufacturers to innovate their production processes. Small-scale firms are also launching nutrient-rich cereals, further boosting the need for modern, high-precision rolling equipment.

In China, the changing diet, fueled by government programs that encourage cereal grain consumption, is driving market expansion. The call for greater production quality and more varied cereal varieties is resulting in greater investment in high-tech rolling machines for cereals. Manufacturers are adding new products to their lines, including whole grains and fortified cereals, to address health-conscious consumers.

Japan is experiencing gradual expansion in the market for cereal with Western nutritional trends continuing to impact consumer demands. The emphasis on health and wellbeing has stimulated growing demand for healthier breakfast alternatives, prompting companies to upgrade production methods. The development of new cereals through changing formulation and upgrading process automation through new rolling machines are driving growth in advanced rolling machine adoption.

In Brazil, the growing middle class and urbanization are fueling the popularity of ready-to-eat cereals. The consumer is looking for healthy and convenient products, and hence manufacturers are upgrading their capacity. The market for cereal rolling machines is increasing as manufacturers aim to improve efficiency, serve the domestic market, and target the export market in the Latin American region.

The market for cereal rolling machines is still moderately concentrated, with a combination of renowned global giants and up-and-coming regional producers vying for market share. Major players reign supreme through technology upgrades, mechanization, and mass production capacities that assure high efficiency and uniformity in the process of cereal processing to meet growing global demand.

Regional players expand their role proactively with an emphasis on inexpensive solutions and individualized rolling machinery to suit distinct cereals. With the advantage of being able to provide flexibility at a cost, they manage to compete against multinational companies, especially in up-and-coming economies where the need for localized as well as smaller-scale cereal making is growing.

Strategic mergers and acquisitions lead to market concentration as industry giants invest in R&D to optimize machine efficiency, minimize energy expenditure, and attain sustainability targets. Firms relentlessly modernize equipment with AI-enabled automation and precision rolling technology to meet the surging demand for varied cereal items.

As health-aware and sustainability-oriented consumers become more prominent, producers incorporate green and energy-saving designs into their equipment. They create adjustable and modular rolling systems to facilitate the manufacture of organic, gluten-free, and nutrient-dense cereals, further consolidating their market leadership in the face of shifting industry trends.

Major Developments

The market for cereal rolling machines is competitive, with international players emphasizing technological innovation to improve production efficiency. Top players invest in automation, artificial intelligence-based control systems, and energy-efficient designs to address changing industry needs. Their capacity to provide high-speed, precision rolling solutions provides them with a strong competitive edge.

Regional players compete on affordability and tailor-made solutions for medium and small-scale cereal manufacturers. They serve specialty cereal types like organic, gluten-free, and fortified cereals. Their capacity to adjust locally and provide support services after selling enhances their acceptability in increasingly expanding cereal demand in emerging countries.

Market leaders increase their footprint through strategic alliances, acquisitions, and investments in research and development. They partner with food companies to create rolling machines that can handle new cereal recipes, such as plant-based and protein-fortified varieties. Their focus on innovation allows them to continue leading in a changing food processing environment.

Sustainability is instrumental in determining the competitive landscape, as companies invest in energy-saving, environmentally friendly, and waste-minimizing rolling technologies. Manufacturers with lower-carbon-emitting rolling machines and biodegradable packaging solutions are favored by ecologically aware brands willing to cooperate with sustainability objectives, thereby gaining a competitive advantage in the global market.

The market is anticipated to reach USD 1.1 billion in 2025.

The market is predicted to reach a size of USD 1.8 billion by 2035.

Prominent players include Maseto Technologies, FH SCHULE Mühlenbau, Nestle, Kellogg Co., and others.

With respect to product type, the market is classified into hot cereal, ready-to-eat cereal, flaked cereals, puffed cereals, shredded cereals, and others.

In terms of end-use, the market is segmented into roots, grain, mixtures for dairy substitutes, the milling industry, agricultural, and balanced feed mix.

In terms of automation, the market is divided into automatic, manual, and semi-automatic.

In terms of region, the market is segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Coffee Roaster Machine Market Analysis by Product Type, Capacity, Control, Heat Source and Application Through 2035

Indoor Smokehouses & Pig Roasters Market – Smoked Meat Processing 2025 to 2035

Brewing Boiler Market Analysis by Material Type, Application, Automation, and Region 2025 to 2035

Flake Ice Machines Market - Industry Growth & Market Demand 2025 to 2035

Exhaust Hood Filters & Cleaning Kits Market – Market Innovations & Industry Growth 2025 to 2035

Catering Food Warmers Market Analysis by Product Type, End Use, Sales Channel, and Region Forecast Through 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.