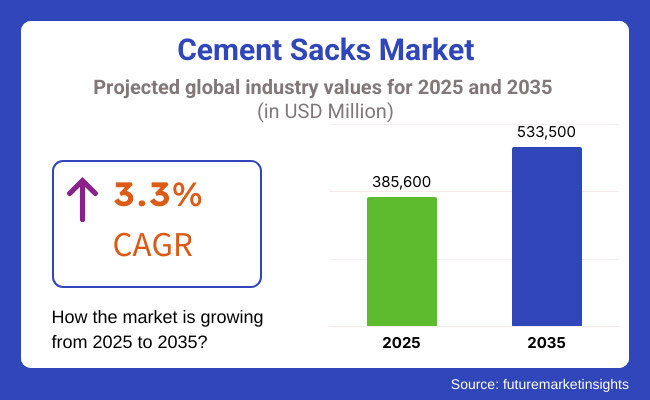

The market is projected to reach USD 3,85,600 Million in 2025 and is expected to grow to USD 5,33,500 Million by 2035, registering a CAGR of 3.3% over the forecast period. Increasing investments in infrastructure development, smart city projects, and sustainable construction materials are boosting demand for high-strength, lightweight, and environmentally friendly cement sacks. Additionally, advancements in multi-layered and anti-leak packaging technologies are shaping the industry's future.

Between 2025 and 2035, cement sacks is forecast to grow steadily strong. Thanks to the increase in the global construction industry Rapid urbanization and infrastructure development in conjunction with greater government expenditure on residential, commercial and industrial projects have markedly driven cement demand hence the need for strong new sacks of cements.

These sacks are necessary for the bulk transport and storage of cement, offering properties such as damp resistance, high strength, long life span. Moreover, strict regulations governing packaged cement and the need to reduce waste during transit might cause manufacturers to develop more innovative sack designs that not only surpass other products in terms of both strength and function.

In response to the increasing concern for ecological protection and as regulations push more companies into sustainable material policies, the market is also beginning to turn in favor of environment-friendly cement packaging solutions.

With people increasingly disposed towards biodegradable, adaptable joints, or even light enough for sacks, manufacturers are driven to produce alternatives potentially propping the burden of energy and cost on kraft paper, polypropylene fabric and novel composite materials.

Technological strides made in materials for sacks, such as the barrier-high-strength paper-sack seen right here, still further turn things around by up-to-date methods. Apart from those, companies are also exploring digital printing and smart packaging to improve brand reputation, traceability of products, and the efficiency of supply chains.

As sustainability and innovation take center stage, the cement sacks market is now expected to change and develop at the same time with an eye toward both performance and environmental responsibility.

Explore FMI!

Book a free demo

North America holds a notable position in the Cement Sacks Market due to the escalating necessity for robust and water-resistant cement packaging alternatives, swelling approval of eco-friendly bags, and infrastructure modernization projects. The United States and Canada guide the region owing to administrative strategies encouraging sustainable construction and innovations in degradable bag manufacturing.

Furthermore, the increasing utilization of paper-based and woven polypropylene cement bags coupled with heightened investments in clever packaging technologies are driving groundbreaking changes. Additionally, the growing focus on decreasing plastic waste and broadening metropolitan infrastructure initiatives are additionally contributing to market growth.

The rising demand has led manufacturers to concentrate on developing advanced solutions to satisfy customer needs for high strength and printability along with environmental friendliness.

Europe continues to hold a substantial share of the Cement Sacks Market due to the environmentally-conscious stances taken by many of its largest constituent countries. Germany, the United Kingdom, France, and Italy have emerged as leaders with regards to sustainable cement packaging through their implementation of strict emission regulations and innovations in lightweight sack construction.

Both the European Union's Packaging Waste Directive and its Circular Economy Action Plan have promoted complete recyclability and compostability of cement sack materials.

Within the region, the construction industry is progressively adopting paper and hybrid bags in place of plastic varieties.

These novel solutions provide robustness on par with traditional options while minimizing polymer application. Simultaneously, technical refinements pertaining to coating substances, anti-leak lamination, and dust-free packaging have served to stimulate additional market growth.

Through regulatory drivers and cutting-edge material science, Europe maintains its prominence in this industrial sphere.

The cement sacks market across the expansive Asia-Pacific region is undeniably primed for vigorous growth, propelled forward by the rapid urbanization enveloping vast swaths of territory, colossal infrastructure projects receiving state sponsorship, and a construction frenzy transforming the very landscape. In countries such as China, India, Japan, and South Korea cement packaging demands are escalating dramatically to meet the requirements of both commercial and residential building booms.

Meanwhile, cement producers will redouble their efforts to adequately package their products and dispatch them to the far-flung places where they are so sorely needed in order to energize economic development and improve living standards for countless individuals.

Many smaller developing nations in the region also anticipate sizeable cement packaging requirements while undertaking ambitious development schemes to strengthen their economies and living standards in the coming years.

While some nations experience galloping development of cities and public works, others find themselves with surging requirements for cement bundles from household renovation and new homes. Meanwhile, the demand is just as vigorous but differs somewhat across the diverse countries of the area.

Challenges

Environmental Concerns and High Production Costs

One of the largest difficulties dealing with the cement bag sector relates to ecological issues involving bags constructed of plastic, specifically woven polypropylene pockets that exacerbate disposable refuse lacking the power to degrade. In addition, governing bodies attempting to lessen plastic bundling are compelling manufacturers towards pricier alternatives that can decompose or be repeatedly used.

An additional difficulty lies in the lofty manufacturing expense of multi-layered and dampness-resistant bags, which influences pricing tactics and net income boundaries for cement manufacturers and wrapping suppliers. Disturbances to the supply chain and fluctuating expenses for raw materials also present restrictions to large-scale making and circulation.

Occasional shortages in basic materials can strangle production, while intermittent spikes in commodity pricing may compress profit margins to the breaking point. A more stable supply base and improved logistical coordination could help alleviate these periodic fluctuations that introduce problematic unpredictability into operations.

Opportunities

Smart Packaging, Automation, and Biodegradable Alternatives

Despite numerous roadblocks, the Concrete Sacks Market presents significant development possibilities. The ascent of keen bundling innovations, including RFID-empowered following, robotized filling frameworks, and AI-driven material streamlining, is improving inventory network proficiency and item genuineness.

The diminishing adoption of biodegradable and degradable concrete sacks, made of starch-based polymers, plant fiber blends, and propelled paper-based layers, is making new market chances for supportability centered bundling producers. Additionally, computerized concrete sack creation, AI-improved quality control, and computerized printing advances are enhancing cost proficiency and customization in concrete sack assembling.

The development of module development, prefabricated structural arrangements, and high-execution cement blends is additionally driving interest for altered concrete sack plans with improved sealing and anti-dust properties. Developing business sectors in Latin America, Africa, and the Middle East are additionally offering extension open doors because of quick modernization and foundation improvement ventures.

The interest for customized textures with progressed sealing and dust avoidance highlights is especially high.

Between 2020 and 2024, the cement sacks market experienced steady growth, driven by rising construction activities, infrastructure development, and urbanization in emerging economies. Cement sacks, essential for secure transportation and storage of cement, saw increased demand due to expansion in residential, commercial, and industrial construction projects.

The market also benefited from innovations in multi-wall paper sacks, woven polypropylene (PP) bags, and moisture-resistant packaging solutions to enhance durability and prevent cement wastage.

Between 2025 and 2035, the cement sacks market will undergo transformative advancements, driven by AI-powered material optimization, smart tracking solutions, and fully biodegradable packaging alternatives. The introduction of nanocoated, moisture-proof paper cement sacks and bio-based woven polymer alternatives will improve strength, sustainability, and resistance to extreme weather conditions. AI-driven real-time quality control in sack production will reduce material waste and optimize cost efficiency.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 |

|---|---|

| Regulatory Landscape | Stricter policies on plastic waste, recycling mandates, and lightweight packaging efficiency. |

| Technological Advancements | Growth in moisture-resistant multi-layer paper sacks, PP-woven sacks, and bulk cement bagging solutions. |

| Industry Applications | Used in residential, commercial, and industrial construction projects. |

| Adoption of Smart Equipment | Traditional cement sack filling and sealing systems. |

| Sustainability & Cost Efficiency | Transition toward recyclable sacks, reduced material usage, and lightweight cement packaging. |

| Data Analytics & Predictive Modeling | Use of basic packaging lifecycle assessments and cement sack performance tracking. |

| Production & Supply Chain Dynamics | Challenges in raw material price volatility, waste management, and logistics inefficiencies. |

| Market Growth Drivers | Growth fueled by global infrastructure expansion, urbanization, and demand for durable packaging. |

| Market Shift | 2025 to 2035 |

|---|---|

| Regulatory Landscape | Blockchain-based sack traceability, AI-driven compliance tracking, and carbon-neutral packaging certifications. |

| Technological Advancements | AI-optimized material strength, bio-based cement sacks, and self-degradable packaging innovations. |

| Industry Applications | Expanded into smart construction logistics, AI-powered inventory management, and automated cement packaging solutions. |

| Adoption of Smart Equipment | IoT-connected cement sack tracking, real-time packaging quality monitoring, and AI-powered demand forecasting. |

| Sustainability & Cost Efficiency | Zero-waste cement packaging, biodegradable smart sacks, and AI-driven production efficiency. |

| Data Analytics & Predictive Modeling | AI-driven demand forecasting, blockchain-backed supply chain optimization, and real-time cement packaging analytics. |

| Production & Supply Chain Dynamics | Decentralized sack manufacturing hubs, AI-enhanced quality control, and predictive material usage modeling. |

| Market Growth Drivers | Future expansion driven by AI-powered packaging innovation, sustainable material advancements, and smart construction logistics. |

The Cement Sacks Market in the United States is experiencing steady growth, driven by increasing infrastructure projects, rising demand for sustainable packaging solutions, and advancements in sack material technology. The USA Environmental Protection Agency (EPA) is promoting the use of biodegradable and recyclable cement sacks to reduce environmental impact.

The growth of residential and commercial construction, highway development, and renovation projects is fueling demand for high-strength, moisture-resistant, and easy-to-handle cement sacks. Additionally, innovations in multi-layer paper sacks and woven polypropylene (PP) sacks are enhancing durability and storage efficiency.

| Country | CAGR (2025 to 2035) |

|---|---|

| USA | 3.5% |

The Cement Sacks Market in the United Kingdom is expanding due to rising construction activities, increasing emphasis on sustainable building materials, and government regulations promoting recyclable packaging solutions. The UK Environment Agency is encouraging manufacturers to develop paper-based and compostable cement sacks to reduce plastic waste.

The growth of urban redevelopment projects and commercial real estate expansion is driving demand for durable, water-resistant cement sacks that ensure better handling and protection against weather conditions. Additionally, the adoption of bulk and lightweight packaging formats is further boosting market innovation.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK | 3.1% |

In the European Union's Cement Sacks Market, continued growth is now being made possible by the European Union's strict regulations on packaging waste, consumers' awareness of environmental protection problems in large part due to changes towards more fuel-efficient vehicles as well as home heating methods. The industry's material producers are increasingly using eco-friendly raw materials.

Plus, infrastructure construction within more and more countries serves to stimulate consumption opportunities for that new product. The European Green Deal and Circular Economy Action Plan call upon cement manufacturers to switch over sack materials from non- recyclable or non- energy-efficient materials. Germany, France and Italy have the largest market, with manufacturers focusing on high-performance sack designs including anti-slide surfaces and UV-resistant materials.

They also possess dustproof sealing technology. Added to this, the trend toward lightly manufactured cement means that consumers now need to find environmentally friendly ways where sustainable solutions are required.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union (EU) | 3.3% |

Amidst urbanization that has population on the increase and ever more buildings under construction, the Cement Sacks Market in Japan's expansion is clear. In response to a question from reporters at Tokyo Press Club, Mr. Toru Inoue, head of White Cement Association, said that with Japan still recovering from the March 11 earthquake and tsunami disaster there is an increased need for anti-seismic cement transportation devices.

The use of high-durability, recyclable cement sacks currently being recommended to construction industry workers is a result of the Japanese Ministry of the Environment's policy priority on environment-friendly products.

Japanese enterprises are developing multi-layer paper and polymer-based cement sacks with protection against moisture as well as anti-tear functions. This not only enhances labor efficiency by making things easier to move around, it also reduces cement wastage. Meanwhile, the growth of prefabricated construction and modular buildings is driving demand for tailor-made sack packaging solutions.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 3.4% |

In South Korea, the Cement Sacks Market is in good shape as the general macro situation continues to drive businesses. The South Korean ministry of Environment is advocating for biodegradable and energy-efficient cement sacks in order to meet the country's own sustainable development targets.

As urban development contributes to the creation of more and more commercial infrastructure, there has naturally been a great demand for high-strength woven polypropylene (PP) sacks which offer good resistance against tearing and an extended shelf life. Moreover the spread of automated cement filling and handling systems is enhancing the demand for specifically developed sack formats.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 3.6% |

Increasing construction activity has seen the Cement Sacks Market expand progressively. The demand for high-strength, moisture-resistant, eco-friendly packaging materials is rising together with cement production. Among different material types, polypropylene (PP) and unbleached paper currently dominate this market, enjoying good durability and eco-friendliness

Polypropylene (PP) bags are the most widely used in the cement industry: they are extremely strong, tearproof and can withstand rough handling during transport and storage. These bags are light but strong, and not at all penetrated by moisture. They keep cement free from humidity which would otherwise shorten its life span.

Woven PP sacks are finding an ever-increasing role in the concrete industry: they not only have a high load-bearing capacity and are exceptionally durable, they're also relatively easy to re-use for the same purpose. Moreover, advanced barrier coatings give laminate PP bags good weather resistance and reduced risk of leakage.

There are some difficulties. Although these plastic bags are now widely available there are environmental concerns about the manufacture and disposal of them. Yet new developments like recyclable PP materials or environmentally friendly blends of plastic have helped to level the playing field. Sack designs have grown more refined too, using less polymer in order to offer a cleaner break for nature.

Unbleached paper bags are increasingly the packaging carrier of choice for cement especially in regions with strict environmental regulations and bans on plastics. Such bags are renewable, biodegradable and have low carbon footprint. They are also an attractive option for cement manufacturers looking to green their packaging.

Multi-layered unbleached paper sacks with high-strength coatings are in increasing demand because they offer better resistance to tearing and moisture than traditional paper sacks. Adoption of progressive water-repellent paper surface treatments and the development of solid fibre technology are raising the durability and storage performance of paper-based cement sacks.

Paper sacks are more susceptible to tearing and moisture absorption as compared to the plastic alternative. Manufacturers are looking to address this by developing hybrid paper/plastic sack solutions as well as applying bio-based coats to improve water resistance while preserving an environmentally friendly material.

The demand for cement sacks is primarily driven by valve sacks and open mouth sacks, as both types offer easy filling, secure sealing, and improved handling efficiency.

Valve sacks are the packets most widely adopted for cement, as they allow for rapid and mechanized filling with minimal dust emission or spillage. The packets come equipped with self-sealing valves, thus cement doesn't require additional sealing at all any more.

As the trend toward high-speed filling machines in cement plants continues, valve sacks are in demand for a still other reason. They help to improve efficiency in production while reducing waste in packaging materials. Polypropylene and multi-layer paper valve sacks are also becoming more popular because of their increased strength and resistance to rupture during handling or transport.

In spite of their high efficiency, challenges such as limited reusability or cost discrepancies remain people's worries, In view of the above bag designs are then being improved; with breathable materials and anti-skid coatings. And now as always ought to be the case reinforcement of valves is most important, so it needs reinforcement mechanisms. The result is improved performance, greater durability while being appreciable cost-effective.

Open mouth sacks for hand based packaging of cement is particularly favored in construction projects with small budgets and in emerging markets in which an automatic filling system is still a rarity. These sacks are easy to fill, tie and pile up, so they are quite suitable for local distribution and retail sale of cement.

The demand for paper open mouth sacks is increasing in green markets such as requiring ecology and reduction of plastic varieties, biodegradable recyclable packing materials become preferred products.

In addition, custom printed open mouth sacks are on the rise, with cement brands keen to get across their unique selling points and the product visibility that differentiation implies. For bulk cement production, however, open mouth sacks are less effective and require sealing by hand, a problem exacerbated when used in production lines. Breakthroughs in self-sealing paper sacks, plastic-paper composites and tamper-evident closures would improve the usability and life expectancy of open mouth sacks further.

The Cement Sacks Market's expansion is driven by the growing demand for environmentally friendly packaging solutions that are both durable and reasonable priced in construction and building materials field, Increasing infrastructure projects, growing cement production and research on lightweight but high-strength sack fabrics also promote market growth.

Bag makers are developing multi-layer paper sacks or polypropylene (PP) woven sacks, and producing biodegradable cement packaging which enhances durability, moisture resistance, recyclability. The market includes major packaging manufacturers, industrial bag suppliers, environmental packaging innovators. Together, these three different areas of expertise have contributed to innovations like clean bags, tamper-evident bags and high-barrier cement sacks.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Mondi Group | 18-22% |

| Billerud AB | 12-16% |

| UPM-Kymmene Corporation | 10-14% |

| Klabin S.A. | 8-12% |

| LC Packaging International | 6-10% |

| Other Companies (combined) | 30-40% |

| Company Name | Key Offerings/Activities |

|---|---|

| Mondi Group | Produces high-strength, multi-ply paper and PP-based cement sacks with moisture barriers. |

| Billerud AB | Specializes in sustainable, recyclable cement sacks made from reinforced kraft paper. |

| UPM-Kymmene Corporation | Manufactures biodegradable and fiber-based cement packaging solutions. |

| Klabin S.A. | Develops high-capacity, tear-resistant cement bags with dust-free filling technology. |

| LC Packaging International | Focuses on customized PP woven cement sacks with enhanced UV protection. |

Mondi Group (18-22%)

Mondi is a global leader in cement sack packaging, offering durable, lightweight, and moisture-resistant sacks for cement and building materials.

Billerud AB (12-16%)

Billerud specializes in reinforced kraft paper cement sacks, ensuring high tear resistance and sustainable packaging solutions.

UPM-Kymmene Corporation (10-14%)

UPM focuses on biodegradable cement sacks, integrating fiber-based materials for eco-friendly cement packaging.

Klabin S.A. (8-12%)

Klabin develops tear-resistant, high-barrier cement sacks, optimizing dust-free filling and extended shelf life.

LC Packaging International (6-10%)

LC Packaging provides UV-protected, woven PP cement sacks, catering to high-strength and long-term storage requirements.

Other Key Players (30-40% Combined)

Several packaging manufacturers, industrial bag suppliers, and sustainability-focused companies contribute to advancements in cement sack durability, recyclability, and moisture protection. These include:

The overall market size for the Cement Sacks Market was USD 3,85,600 Million in 2025.

The Cement Sacks Market is expected to reach USD 5,33,500 Million in 2035.

Increasing construction activities, rising demand for durable and eco-friendly packaging, and advancements in moisture-resistant sack materials will drive market growth.

China, India, the USA, Germany, and Brazil are key contributors.

Multi-wall paper sacks are expected to dominate due to their strength, biodegradability, and superior protection against moisture.

BOPP Film Market Analysis by Thickness, Packaging Format, and End-use Industry Through 2025 to 2035

Korea Tape Dispenser Market Analysis by Material, Product Type, Technology, End Use, and Region through 2025 to 2035

Japan Heavy-duty Corrugated Packaging Market Analysis based on Product Type, Board type, Capacity, End use and City through 2025 to 2035

Corrugated Board Market Analysis by Material and Application Through 2035

Waterproof Packaging Market Trends - Demand & Industry Forecast 2025 to 2035

Thermochromic Labels Market Insights - Innovations & Growth 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.