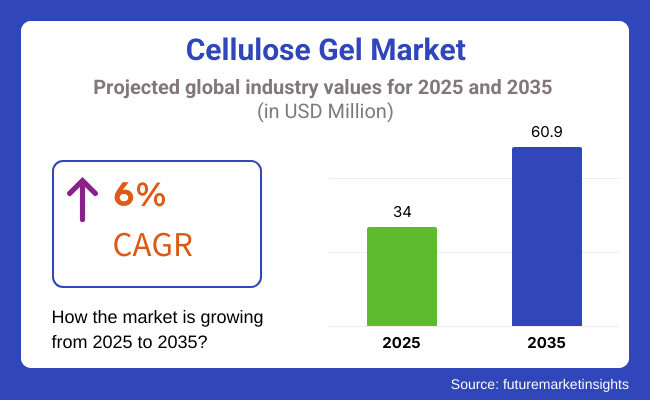

The market is projected to reach USD 34 Million in 2025 and is expected to grow to USD 60.9 Million by 2035, registering a CAGR of 6% over the forecast period. Increasing consumer preference for natural and functional food ingredients, rising demand for dietary supplements, and expanding applications in drug formulation are fueling market expansion. Additionally, innovations in cellulose extraction, biodegradable alternatives, and nano-cellulose applications are shaping the industry's future.

Between 2025 and 2035, it appears that the Cellulose Gel Market will continue to grow as plant-based and clean-label dietary trends drive consumer demand across various industries.

As food manufacturers continue to emphasize natural, non-GMO and allergen-free additives for their ingredients, cellulose gel, also known as microcrystalline cellulose (MCC), is gaining recognition as a thickening agent that adds no flavor, and also an emulsifying and anti-caking agent.

The burgeoning demand for low-calorie and fat reduced products in the food and beverage industry drives market expansion further. Cellulose gel can add texture and do a fine job keeping moisture without adding extra calories. In addition, it acts as a stabilizer in dairy alternatives, processed meats, and bakery products-which fits quite nicely with the current trend towards functional and sustainable food ingredients.

Along with the development of pharmaceutical auxiliary materials, cellenese gel is used more and more in the preparation of medicines. In tablet processing as a kind of disintegrating and binding agent, MCC helps the production to treat, packet, stabilize release rates of drug and can be taken in by body effectively. Cellulose gel demand is versus the changing backdrop for an up-and-coming pharmaceutical industry that is expected to be based in emerging markets.

As an eco-friendly alternative to other materials, this has found a particular niche among skin care and cosmetic manufacturers. With the new tendency of consumers toward greener products that are both sustainable and in touch with nature, use has also been increasing lately in skin care, as well as hair products and color cosmetics.

Explore FMI!

Book a free demo

The cellulose gel market will increase in North America, mainly due to increasing consumer demand for food additives that are natural, the adoption of MCC in pharmaceuticals and the fact that regulations are disposed toward plant cell excipients.

The USA Canada occupies the most important position than others. There is a strong demand for cellulose-based stabilizers in dairy products, baked goods and nutraceuticals.

The approval of MCC by the FDA as a food additive or excipients has led to its extensive use in oral drug formulations. Additionally, as plant-based or functional food markets increase in size, innovation continues to be made on cellulose-based texture enhancers.

In Europe represents a big percentage of Cellulose Gel Market. Germany, France, the UK, Italy and so on major countries for sustainable food storage products, clean label food formulation as well as new drugs developed with pharmaceutical breakthrough technology these will all stimulate review of markets in which artificial chemicals occur unnaturally through human intervention.

Hence, on the European Food Safety Authority (EFSA) and other natural cellulose-based alternatives have become the preferred choice of EU food additive.This is also one reason that market prospects in this field are increasingly good.

In Europe, for example An increasing trend in pharmaceutical industry fields is to use MCC as a binder of tablets or capsules. In addition to that, desire for biodegradable cosmetics such as cellulose-based emulsifiers in skincare and make-ups is further expanding market possibilities.

With burgeoning processed food consumption, increasing capital investment in pharmaceutical manufacturing, and growing eco-awareness of plant-derived ingredients, the Asia-Pacific region is expected to provide the most impetus for CAGR.

A leading provider of MCCs and pharmaceutical excipients as well as dietary supplement formulations, China has become an industry giant.

Japan also performs well in this arena too; it has lately come to exceed China in producing MCC varieties of pharmaceutical excipients. As Japan and China can no longer simply shift production abroad, South Korea and India have not been far behind their neighbours when it comes to developing new MCC products for the dietary supplement industry.

China’s expanding food processing sector and the government initiative to promote the use of natural food additives are helping increase demand for cellulose gel in functional beverages, dairy, and frozen foods. India’s booming nutraceuticals and ayurveda-based supplements sector also means that MCC is being used more extensively in herbal or plant-based tablets.

Additionally, Japan and South Korea are leading the world in biodegradable personal care product innovations. They are incorporating cellulose gels into a variety of formulations - lotions, creams, and facial masks.

Challenges

High Production Costs and Regulatory Complexities

The biggest obstacle in the Cellulose Gel Market is often high costs of production- especially when it comes to pharmaceutical grade and high purity Cellulose gel. To increase production costs even further, the complicated extraction process and numerous regulations surrounding excipients and food additives must not be overlooked.

In addition, different countries have different regulations: the EU has specific restrictions on some cellulose-based food additives; and strict FDA requirements for pharmaceutical applications provide obstacles to global market expansion.

With the advent of man-made alternatives as well as competition from other plant-based stabilizers such as pectin, agar, and xanthan gum, this even further impacts the market diffusion.

Opportunities

Growth in Plant-Based and Sustainable Packaging Applications

Despite facing various hurdles, meaningful opportunities still exist within the ever-evolving Cellulose Gel industry. Surging interest in plant-based and vegan alternatives, such those replacing dairy, containing no gluten or reduced in fat, has contributed to widened usage of cellulose gel as a texture amplifier and stabilizer.

The emergence of sustainable packaging remedies harnessing nano-cellulose and films derived from microcrystalline cellulose introduces promising prospects within the food and pharmaceutical packaging domains.

In addition, cutting-edge advances in controlled-medication dispersal and bioadhesive formulations leveraging microcrystalline cellulose are enhancing functionality further within the pharmaceutical section.

Surging interest in organic skincare and clean beauty has also fueled incorporation of cellulose gel as a natural thickener across lotions, shampoos and cosmetic emulsions. Looking ahead, the development of artificial intelligence-driven food formulation and intelligent ingredient tracing is anticipated to bring greater transparency and accelerated innovation across product development.

From 2020 to 2024, the cellulose gel industry underwent substantial growth driven by rising needs for organic stabilizers, clean-label nourishment ingredients, and lasting individual care formulations.

Cellulose gel, otherwise called microcrystalline cellulose (MCC), obtained recognition in meals & drinks, pharmaceuticals, and cosmetics owing to its thickening, emulsifying, and moisture-retaining houses. This led to a change towards plant-based, non-GMO, and biodegradable choices accelerating industry enlargement, especially in vegan meals merchandise, gluten-free formulations, and programs lowering fats content material.

In addition, new areas of utilization have been explored over this time interval, along with novel purposes in dietary dietary supplements and tissue engineering merchandise. Analysis additionally accelerated on maximizing manufacturing effectivity and improving product high quality requirements to fulfill evolving client and regulatory demands worldwide.

Between 2025 and 2035, the cellulose gel market will undergo tremendous changes promoted by innovations in technology. Artificial intelligence will reshape the production of these gels through customized formulation optimized for specific products. Nanoscale cellulose structures created using bioengineering will deliver enhanced texture and water control.

Beverages and foods containing judiciously applied cellulose gels tailored for each recipe by AI will gain stability while delighting consumers' senses. Concurrently, blockchain will provide end-to-end traceability of gel-based ingredients from field to factory to final products on shelves as this non-sentient technology tracks transformation and transactions.

Altogether, these advances will transform the cellulose gel industry through unprecedented customization empowered by machine smarts and immutable ledgering of transformations along global supply chains.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 |

|---|---|

| Regulatory Landscape | Compliance with FDA, EFSA, and WHO regulations on food-grade cellulose gel and pharmaceutical excipients. |

| Technological Advancements | Growth in microcrystalline cellulose (MCC), hydrocolloid blends, and emulsifying cellulose formulations. |

| Industry Applications | Used in food & beverages, pharmaceuticals, personal care, and paper & pulp industries. |

| Adoption of Smart Equipment | Traditional chemical extraction and refining processes for cellulose gel production. |

| Sustainability & Cost Efficiency | Adoption of plant-based and biodegradable cellulose sources to meet sustainability goals. |

| Data Analytics & Predictive Modeling | Basic ingredient tracking and supply chain analytics for cellulose gel applications. |

| Production & Supply Chain Dynamics | Challenges in raw material price fluctuations, sourcing limitations, and consumer acceptance. |

| Market Growth Drivers | Growth fueled by demand for clean-label ingredients, plant-based food expansion, and pharmaceutical excipient advancements. |

| Market Shift | 2025 to 2035 |

|---|---|

| Regulatory Landscape | Blockchain-based traceability for cellulose sourcing, AI-driven regulatory compliance, and global clean-label certifications. |

| Technological Advancements | AI-powered formulation optimization, nanocellulose-enhanced gels, and bioengineered cellulose gel derivatives. |

| Industry Applications | Expanded into smart food coatings, AI-personalized skincare, and nanocellulose-based biomedical innovations. |

| Adoption of Smart Equipment | AI-integrated bioprocessing, smart fermentation-based cellulose synthesis, and decentralized biofactories. |

| Sustainability & Cost Efficiency | Zero-waste cellulose production, upcycled agro-waste cellulose, and carbon-negative cellulose biomanufacturing. |

| Data Analytics & Predictive Modeling | AI-driven demand forecasting, blockchain-backed sourcing transparency, and real-time cellulose functionality modeling. |

| Production & Supply Chain Dynamics | Decentralized cellulose bioprocessing hubs, AI-powered cellulose quality control, and blockchain-secured ingredient verification. |

| Market Growth Drivers | Future expansion driven by AI-powered cellulose optimization, smart biopolymer coatings, and next-gen nanocellulose-based innovations. |

The diverse Cellulose Gel industry in the United States has grown steadily due to the increasing demand for clean-label food additives in recent times. The Cellulose Gel market has expanded rapidly with novel pharmaceutical formulations gaining approval and personal care products employing its varied uses more broadly.

The Food and Drug Administration considers cellulose gel, also called microcrystalline cellulose, to be generally recognized as safe for consumption, supporting its prevalence in low-fat meals, supplements and pharmaceuticals designed to maintain health and wellness. A complex network of market factors has intertwined to fuel the rising significance of cellulose gel as food technology and medicine advance their reliance on its multitude of feasible functions.

The growth of plant-founded and gluten-free merchandise continues fueling interest for cellulose gel as a stabilizer and thickening agent. Moreover, the spreading pharmaceutical and nutraceutical sectors are increasing the employment of cellulose gel in pill binding, capsule formulations, as well as controlled drug release applications. The selection extends to garden care products and certain construction materials too. While regulations ensure its safe use, researchers probe new horizons for this remarkable substance.

| Country | CAGR (2025 to 2035) |

|---|---|

| USA | 6.3% |

The Cellulose Gel Market in the United Kingdom has flourished considerably owing to ever-growing customer preference for all-natural food additives, escalating requirement in the pharmaceutical sector, and authoritative focus on clean-label formulations. The UK Food Standards Agency backs using cellulose gel in comestibles, beauty products, and medicines, ensuring adherence to benchmarks of safety and quality. Vegan and gluten-free victuals have gained widespread popularity in current times, propelling demand for cellulose gel as a fat alternative and texture enhancer.

In addition, proliferation of the cosmetics and personal care industry has driven employing cellulose gel in lotions, balms, and skincare items. The gel's solvent and stabilizing properties make it appropriate for a diversity of uses. Moreover, health-conscious British citizens are fueling expansion of the wellness market, presenting opportunities for cellulose gel in novel applications.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK | 5.8% |

The Cellulose Gel marketplace throughout the European Union is observing sturdy progress owing to stringent meals safety rules, rising demand for plant-derived elements, and increasing applications in pharmaceuticals and cosmetics. The European Meals Security Authority (EFSA) has accredited cellulose gel as a meals additive, encouraging its utilization in low-calorie and high-fiber foodstuff. Stringent rules and acceptance by EFSA have aided cellulose gel's rising reputation.

Germany, Italy, and France guide the sector, with meals and pharmaceutical corporations blending cellulose gel into formulations to improve stability, texture, and bioavailability. Producers search to leverage cellulose gel's talent to fortify merchandise organoleptically and functionally. Simultaneously, calls for for sustainable and biodegradable substances additional spur improvement in versatile cellulose-based thickeners and stabilizers. Renewed concentrate on plant-based elements fuels cellulose gel incorporation into an array of European merchandise.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union (EU) | 6.0% |

The Japanese cellulose gel market is prospering significantly due to the robust demand for functional foods, rising pharmaceutical applications, and consumers showing a marked preference for natural cosmetic formulations. The Ministry of Health, Labour, and Welfare has promulgated rigorous quality benchmarks for cellulose gel in sustenance, medicines, and individual care items.

Japanese manufacturers are incorporating cellulose gel in customary and cutting-edge foodstuffs, including dairy substitutes, gluten-free products, and low-fat desserts - aiming to meet the diverse requirements of health-conscious customers. In addition, the mushrooming of premium skincare and anti-aging merchandise is energizing demand for cellulose gel in emulsions and hydrating creams. Traditional Japanese companies view cellulose gel as a promising ingredient that can enhance textures while boosting the nutritional and moisturizing properties of various commodities.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 6.2% |

The South Korean cellulose gel industry has proliferated vigorously with various factors stimulating expansion. Widely, processing foodstuffs have broadened considerably while investment in drug additives has amplified markedly. Additionally, uses in cosmetic recipes are evolving. Oversight is provided by the Ministry of Food and Drug Security which oversees application in edible and medicinal formulations. The MFDS upholds rigorous safety metrics for employment of the gel. The burgeoning of industries such as nourishment production have driven significant market growth. Likewise, outlay in pharmaceutical ingredients has notably fueled development.

Cosmetology too has contributed to evolving applications. Regulation maintains lofty standards are adhered to for inclusion in consumables and prescriptions. The increasing requirements for high-performance skincare and personal care merchandise is energizing the utilization of cellulose gel as a texture modifier and moisture-binding agent.

Additionally, climbing health-aware patron inclinations are steering the request for natural, fiber-wealthy food ingredients. The escalating demand has generated lucrative prospects for cellulose gel providers to expand production and boost research and progress initiatives to satisfy the evolving needs of end-use industries. The administration regulatory framework has additionally provided a predictable commercial enterprise environment for marketplace members.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 6.4% |

The Cellulose Gel Market continues to expand at a swift pace owing to the rising needs for organic stabilizers, thickeners, and texture enhancers across numerous sectors like foods, pharmaceuticals, and individual care items. Of the diverse choices of cellulose gel sources, wood cellulose and cottonseeds cellulose overwhelmingly lead the industry, presenting remarkable functionality, sustainability, and a wide assortment of employable uses.

Wood cellulose is derived from the most plentiful biomass on Earth and forms the basis for an invaluable thickening agent. It is sustainably sourced from fast-growing trees and greenery through environmentally-conscious processes. Cellulose gel extracted from wood is prized for its premium thickening and stabilizing abilities at an affordable cost.

This renewable resource finds widespread application across many consumer sectors. Food companies rely on its unparalleled texture enhancement and suspension characteristics in products spanning breads to sauces and dairy alternatives. The pharmaceutical industry also leverages its cohesive and moisture-retentive properties in medicines and suppositories.

Cosmetic giants utilize its viscofying talents in creams, lotions and potions for the skin.

While concerns over sustainability, expense and future policy changes present challenges, innovation is addressing these issues. Novel extraction methodology emphasizes eco-friendliness from forest to finished formula. Cutting-edge cellulose formulations emphasize biodegradability after use.

Certifications for organic and sustainable forestry practices are facilitating sustained need for this versatile plant derivative.

Cottonseeds cellulose shows promise as a premium alternative for food, pharmaceuticals, and cosmetics relying on purity, safety, and superb suspension abilities. Renowned for outstanding cleanliness and toxicity-free nature, it is a top selection in ingredient listings emphasizing earth-friendly origins.

Within culinary creations and potables, cottonseed cellulose gel serves as a no-calorie substitute for fat while improving consistency. Separately, medication producers leverage its managed release qualities, ensuring better stability and absorption of drugs.

While cottonseed cellulose costs exceed wood-derived choices, its non-GMO traits, chemical-free processing, and eco-friendliness motivate broader acceptance in high-end, natural lines. Anticipated innovations in gentle extraction techniques and biotechnologies may make it more financially competitive.

The demand for cellulose gel is primarily driven by food & beverages and pharmaceutical applications, as both industries seek natural, multifunctional, and stabilizing agents for product formulations.

The food and beverage sector depends heavily on cellulose gel, leveraging its effectualness to thicken, emulsify, and stabilize prepared victuals, milk substitutes, sauces, and reduced fat products. Demand for the herbal stabilizer has expanded as additional formulas changeover to clean labels and plant-based ingredients, with cellulose gel changing fat and enhancing texture in an extraordinary way.

Moreover, potable manufacturers include cellulose gel into nutritious liquids, fruit potables, and protein shakes so as to sustain suspension stability and impede ingredients from separating.

Health-cognizant clients drive the use of cellulose gel over synthetic choices like xanthan gum and carrageenan. Meanwhile, researchers probe latest uses for the thickener in nutraceuticals and alternative clinical applications to boost wellness. The natural stabilizer demonstrates promising possibilities for the future.

However, regulatory hurdles, inconsistent gel properties and formulation incompatibilities continue to present challenges. Advancements in micronized cellulose processing, functional blending strategies and sustainable production methods are expected to further broaden applications of cellulose gel within food and drink.

The pharmaceutical arena relies heavily on cellulose gel, implementing it as a binder, disintegrant, and timed-release operator in pill formulations, capsules, and topical remedies. Its immense water-binding ability, harmless nature, and means to advance bioavailability establish it a pivotal substance in strong and liquid drug formulations.

Pharmaceutical corporations are progressively embracing cellulose gel derived both from lumber and cottonseeds to reinforce drug dependability, better coating productiveness, and optimize dissolution rates in medications. Additionally, its application in dental care items, such as therapeutic gels and mouthwashes, is spreading as all-natural and useful fixings achieve inclination.

In spite of its advantages, expense inconsistencies, administrative submission issues, and competition from different extra components pose tests. In any case, advances in nano-cellulose prescription transporters, biocompatible extra parts, and AI-aided structure outline are relied upon to increment the utilization of cellulose gel in pharmaceutical advancements.

The market for cellulose gel continues to flourish considering the ever-expanding requirements for stabilizers, thickeners, and texture augmenters across diverse industries. Notably, the expansive foodstuffs and potables area widely employs cellulose gels to notably better the sensory experience and preserve constancy.

Similarly, the involved pharmaceutics realm integrates cellulose gels within mechanisms and formulations for controlled medicine dispensation and solubility supervision. In addition, individual care item catalogs probe cellulose gel uses linked to impression, viscosity issues and emulsification troubles.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| FMC Corporation (DuPont) | 18-22% |

| JRS Pharma GmbH & Co. KG | 12-16% |

| Asahi Kasei Corporation | 10-14% |

| Roquette Frères | 8-12% |

| DFE Pharma | 6-10% |

| Other Companies (combined) | 30-40% |

| Company Name | Key Offerings/Activities |

|---|---|

| FMC Corporation (DuPont) | Produces Avicel® microcrystalline cellulose for food, pharmaceuticals, and industrial applications. |

| JRS Pharma GmbH & Co. KG | Specializes in pharmaceutical-grade MCC and cellulose-based excipients for solid dosage formulations. |

| Asahi Kasei Corporation | Manufactures high-performance cellulose gels for food texturization and drug formulation. |

| Roquette Frères | Provides plant-based cellulose gel solutions for stabilizers, coatings, and controlled release formulations. |

| DFE Pharma | Focuses on high-purity cellulose gels for improved tablet binding, disintegration, and viscosity control. |

Key Company Insights

FMC Corporation (DuPont) (18-22%)

FMC Corporation dominates the cellulose gel market, providing high-quality Avicel® MCC for applications in food stabilizers, pharmaceuticals, and industrial formulations.

JRS Pharma GmbH & Co. KG (12-16%)

JRS Pharma specializes in MCC-based excipients, ensuring superior binding and disintegration properties for solid dosage forms.

Asahi Kasei Corporation (10-14%)

Asahi Kasei develops pharmaceutical-grade cellulose gels, catering to advanced drug delivery and food texturization applications.

Roquette Frères (8-12%)

Roquette focuses on sustainable cellulose gels, offering biodegradable and plant-based stabilizers for food, personal care, and pharma industries.

DFE Pharma (6-10%)

DFE Pharma provides high-purity MCC formulations, supporting efficient binding, disintegration, and tablet compaction in pharmaceutical applications.

Other Key Players (30-40% Combined)

Several ingredient manufacturers, specialty chemical firms, and excipient suppliers contribute to advancements in cellulose gel purity, sustainability, and application versatility. These include:

The overall market size for the Cellulose Gel Market was USD 34 Million in 2025.

The Cellulose Gel Market is expected to reach USD 60.9 Million in 2035.

Increasing demand for stabilizers in food and beverages, rising use in pharmaceuticals and cosmetics, and growing preference for plant-based and clean-label ingredients will drive market growth.

The USA, China, Germany, India, and Japan are key contributors.

Food-grade cellulose gel is expected to dominate due to its widespread use as a thickening and stabilizing agent in processed foods.

Japan Avocado Oil Market Analysis - Size, Share & Trends 2025 to 2035

Korea Avocado Oil Market Analysis - Size, Share & Trends 2025 to 2035

Korea Texturized Vegetable Protein Market Analysis – Size, Share & Trends 2025 to 2035

Japan Texturized Vegetable Protein Market Analysis - Size, Share & Trends 2025 to 2035

Western Europe Texturized Vegetable Protein Market Analysis - Size, Share & Trends 2025 to 2035

Western Europe Pea Protein Market Analysis - Size, Share & Trends 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.