The closing and sealing of tins and cardboard boxes are both tasks that all kinds of industries well before the introduction of the internet. Case sealers and closures are essential pieces of equipment in packaging operations, as they ensure that boxes and cartons are properly sealed for transportation, storage,and display.

From simple manual and semi-automatic machines to fully automated systems,these devices are utilized across a vast range of industries including food and beverage, consumer goods, pharmaceuticals, and logistics.

Supply chains are getting more complex and businesses want faster and more reliable packaged at the same time,for this, the demand for superlatively versatile, efficient and customizable sealing equipment is growing. Moreover, innovation in tape and adhesive technologies and the increasing focus on sustainability driving the demand for eco-friendly sealing solutions is boosting the market.

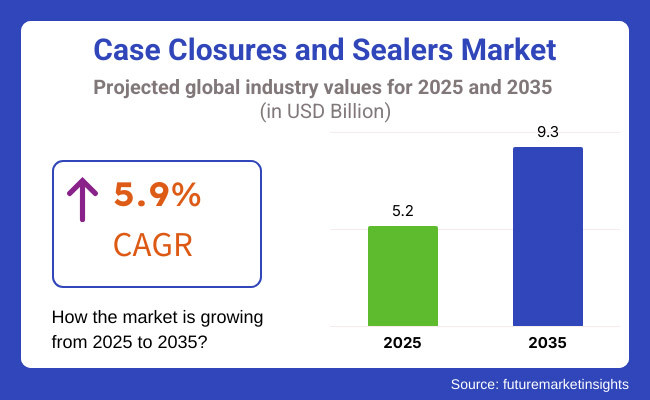

The case closures and sealers market are projected to witness steady growth through 2035, as new innovations with an emphasis on efficiency, durability, and sustainability reshape this market segment. The case closures and sealers market is approximately USD 5.2 Billion in 2025. The market is expected to be worth USD 9.3 Billion by 2035, with a CAGR of 5.9%. The growth is driven by the increasing automation of packaging lines, the growing e-commerce and retail sectors, and improved sealing materials and technologies.

Explore FMI!

Book a free demo

North America is yet another significant market for case closures and sealers and is sustained by an established packaging industry, as well as e-commerce activities in the region.

Continuous investment in robust automated packaging equipment in the United States and Canada can be attributed to high efficiency, cost-saving, and a reliable solution to supply chain operations. Moreover, sustainable materials and waste minimization focus in this region has bolstered the application of innovative sealing technologies and green adhesives.

Europe, who are also known for strict packaging rules, strong sustainability focus and progressive manufacturing. Germany, France, and Italy are leading the market in deploying advanced sealing technologies in packaging operations. Within the food and beverage and pharma and consumer goods sectors, case closures and sealers are also an integral part of providing people with a safe, efficient means of access to packaged products. The increasing demand for environmentally friendly sealing solutions bolsters market growth in Europe.

Factors such as increasing industrialization, the establishment of manufacturing facilities, and a flourishing e-commerce industry have made Asia-Pacific the world's fastest-growing case closures and sealers market. Regions such as China, India, & Japan are seeing high demand for advanced packaging equipment as industries aim to run more efficiently while minimizing the cost of labor.

The growing sizes of the region’s middle-class population and increasing demand for packaged products by consumers are also playing a role in the rising demand for efficient, reliable sealing solutions. The market is estimated to grow significantly, as companies in the Asia-Pacific region are investing in automation and modern packaging technologies.

Challenges

High Equipment Costs, Variability in Packaging Materials, and Maintenance Complexity

While automated sealers, robotic integration, and AI-driven packaging lines have enabled facilities to effectively manage capital investments, many packaging solutions are still untargeted in terms of capital costs. Because of budget restrictions, it is very difficult for small and medium enterprises to adopt high-speed sealing solutions.

Variability in packaging materials is another challenge faced as different case sizes, weights, and materials (corrugated, rigid, or flexible) necessitate tailored sealing solutions that ultimately cause inconsistent results and higher downtime. The increasingly complex sealing equipment maintenance and calibration requirements also impact operating efficiency and drive the need for specialized training and periodic servicing, increasing costs.

Opportunities

Growth in E-commerce Packaging, Smart Automation, and Sustainable Sealing Solutions

These factors pose challenges for the case closures and sealers market, but growth opportunities remain strong through growing demand for e-commerce packaging, automated case sealing solutions, and sustainable adhesive technologies. Rising online shopping and widening global supply chain have led to demand for high-speed, effective and tamper-proof case sealing solutions.

The use of AI-based robotic case sealers and sensor-based automated systems that can be used to enhance accuracy, speed and security in packaging. Market innovation is also being driven by a move towards sustainable sealing technologies, including biodegradable tapes, water-activated adhesives and recyclable case materials.

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Compliance with packaging safety, tamper-evidence, and adhesive chemical regulations. |

| Consumer Trends | Increased demand for durable, tamper-proof, and lightweight packaging solutions. |

| Industry Adoption | Use of semi-automated and manually adjustable case sealers in traditional industries. |

| Supply Chain and Sourcing | Dependence on plastic-based sealing tapes and synthetic adhesives. |

| Market Competition | Dominated by packaging machinery manufacturers and adhesive suppliers. |

| Market Growth Drivers | Growth fueled by rising e-commerce, food and beverage packaging, and global logistics expansion. |

| Sustainability and Environmental Impact | Moderate adoption of eco-friendly adhesives and low-waste packaging designs. |

| Integration of Smart Technologies | Early-stage use of programmable logic controllers (PLCs) and semi-automated case sealing systems. |

| Advancements in Case Sealing Equipment | Development of high-speed adjustable sealers and tamper-evident tape dispensers. |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Stricter sustainability laws, eco-friendly adhesive mandates, and waste reduction policies. |

| Consumer Trends | Growth in customized, recyclable, and AI-powered sealing innovations. |

| Industry Adoption | Expansion into fully automated robotic sealing systems with real-time monitoring and predictive analytics. |

| Supply Chain and Sourcing | Shift toward biodegradable adhesives, water-activated tapes, and recyclable sealing solutions. |

| Market Competition | Entry of AI-driven packaging firms, eco-friendly adhesive startups, and digital packaging innovators. |

| Market Growth Drivers | Accelerated by smart packaging automation, sustainable packaging innovations, and real-time case tracking. |

| Sustainability and Environmental Impact | Large-scale adoption of zero-plastic sealing solutions, carbon-neutral adhesives, and energy-efficient sealers. |

| Integration of Smart Technologies | Expansion into AI-driven quality control, machine learning-based predictive maintenance, and IoT-enabled packaging lines. |

| Advancements in Case Sealing Equipment | Evolution toward self-learning, AI-powered sealing machines with real-time defect detection and adjustment capabilities. |

The USA case closures and sealers market is witnessing gradual growth, due to surge in demand for automated packaging solutions in food & beverage, e-commerce and pharmaceuticals industries. Advancements in parallel case sealing technology are being driven by the move toward efficiency, cost savings and sustainability in packaging operations. Further, manufacturers are incorporating smart automation and AI-based sealing system to boost productivity.

| Country | CAGR (2025 to 2035) |

|---|---|

| USA | 6.0% |

The United Kingdom case closures and sealers market records outstanding growth, primarily due to businesses across logistics, food processing, and consumer goods sectors in the UK searching for reliable and effective packaging solutions. The demand for high-speed case sealing systems was driven by the growing trend of online shopping and e-commerce fulfillment centers.

Furthermore, compliance with sustainability regulations will further contribute to the use of eco-friendly adhesive and sealing materials for sustainable packaging initiatives driven by regulations have been gaining momentum.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK | 5.8% |

The case closures and sealers market in Europe is registering substantially increasing growth with scalable investments in automated vertical packaging solutions. Avoidance of plastic in all forms of sustainable packaging and reduction in waste due to regulations further facilitate manufacturers to move towards energy-efficient and recyclable sealing solutions. Market demand is further being driven by rapidly expanding food & beverage and pharmaceutical industries.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union (EU) | 5.9% |

The major driving factors for the market in Japan are the country’s domination in precision manufacturing and automated packaging solutions. Increasing need for speed, compact, and smart packaging equipment in electronic, pharmaceutical, and food & beverage industries augments the growth of the market. Moreover, technological advancements in case sealing robotic solutions are improving packaging line efficiency.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 5.8% |

The South Korea case closures and sealers market is anticipated to ascend with the growing demand from the logistics, food & beverage and electronics industries. Intelligent sealing solutions are gaining traction as the automation of warehousing and factories increases. Moreover, a growing trend of sustainability initiatives promoting the use of eco-friendly adhesive and packaging material is also spurring the global demand for these products.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 6.0% |

As the industries are looking for automated, durable, and high-performance sealing solutions in order to optimize the packaging process, reduce the usage of manual labor, and enhance the product safety, the Case Closures and Sealers Market is experiencing substantial growth. From food & beverage to pharmaceuticals to e-commerce logistics, companies in various industries have already started investing in high-end sealing equipment to automate the sealing process so that it can be performed at a consistent, efficient rate while complying with stringent regulations.

The growing movement towards smart packaging, sustainability, Industry 4.0 innovations is also giving rise to the demand in automated case closure & sealing solutions. It covers the following segments by Equipment Type (Manual, Semi-Automatic, Fully-Automatic), Application (Food & Beverages Packaging, Electrical & Electronics Packaging, Agricultural Packaging, Healthcare & Pharmaceuticals Packaging, Others)

In terms of type, the largest share of case closures and sealers market is occupied by fully-automatic case closures and sealers as manufacturers favor high-speed, precision-based, and cost-effective packaging operations. These machines operate autonomously, providing consistent sealing, fewer errors, and enhanced output in production lines and distribution households.

Fully-automatic case sealers are used extensively in packaging operations for food & beverage, pharmaceuticals, and e-commerce logistics, where high volumes of production are encountered, and consistency and reliability is paramount.

Compared to their predecessor types, modern fully-automatic sealers are equipped with automated monitoring systems that employ advanced artificial intelligence hence better performance, robotic integration, and sensor-based alignment that prevents waste. Moreover, leak sealing technologies that are energy-efficient, eco-friendly, and biodegradable are growing in popularity to meet global sustainability targets.

Semi-automatic case closures and sealers are also important to the market, especially for SMEs, specialty packaging units, and businesses requiring flexible production. Because of this, these machines strike a perfect partnership between automation, and hand control, to provide customized packaging and reduction of labor. Semi-automatic sealers are ideal for businesses that manufacture smaller quantities of product or regularly need to change their packaging, as they are both low-cost and versatile.

Hand case closures and other basic machines are slowly being phased out in favor of more automated solutions, but still cater to small-scale, local, and more economically-minded manufacturers. These machines find their most useful application in the packaging of handcrafted or specialized products, where precision is required for sealing but automation isn't economically viable.

The case closures and sealers market by application segment was led by the food and beverage category, attributed to increasing demand for packaged food, ready-to-eat meals, and convenience products, driving the growth of this segment. Considering the global nature of food supply chains and a rise in hygiene and safety demand, manufacturers are commonly integrating high-performance sealing machines to provide tamper-proof, contamination-free, and extended shelf-life packaging.

Beverage packaging automated sealing solutions are getting more complex, as manufacturers increasingly focus on minimizing plastic usage, ideal recyclable packaging, and tight seals that eliminate leaks and spills.

Additional consumers were derived from the growing e-commerce grocery business and the rise in direct-to-consumer food delivery services, both driving the need for efficient and protective case closures for transport.

The healthcare and pharmaceutical sector is another major contributor to the growth of the market. With the growing production of prescription drugs, vaccines, and medical devices, there is a surging need for secure, sterile, and regulation-compliant packaging options. The importance of sealing machines is significant in providing safe sacrificial tamper-proof and contamination resistant packaging for medical equipment, diagnostic kits and life-saving drugs.

The electrical & electronics packaging application segment is also thriving, wherein manufacturers prefer using protective and anti-static damage-resistant packaging solutions for their delicate components. Strong global demand for consumer electronics, semiconductors, industrial hardware and growth in electronic copiers, transformers, and automotive industries will also lead to an increased need for quality case closures and sealers for packaging products.

Similarly, supply and demand for more water- and weatherproof packaging is increasing for things like bulk grain-bag sealing, seed packaging and pesticides as precision farming and agribusiness exports ramp up.

The case closers & sealers market is broadly classified into various segments, including product type, application, and region. To improve packaging durability, cost efficiency, and sustainability, companies are concentrating on AI-enabled sealing technology, high-speed automation, and eco-friendly adhesive solutions.

Comprising industrial packaging equipment manufacturers, sealing technology providers, and automation solution firms, this market drives innovations such as case sealing advancements, AI-enabled quality control, and sustainable adhesive innovations.

Market Share Analysis by Key Players & Packaging Equipment Manufacturers

| Company Name | Estimated Market Share (%) |

|---|---|

| 3M Company | 18-22% |

| Illinois Tool Works Inc. (ITW) | 12-16% |

| Bosch Packaging Technology (Syntegon Technology) | 10-14% |

| Wexxar Bel (ProMach) | 8-12% |

| Lantech Inc. | 5-9% |

| Other Packaging Machinery Manufacturers (combined) | 30-40% |

| Company Name | Key Offerings/Activities |

|---|---|

| 3M Company | Develops AI-powered case sealing solutions, high-performance adhesive tapes, and automated packaging systems. |

| Illinois Tool Works Inc. (ITW) | Specializes in automatic and semi-automatic case sealing machines, AI-assisted precision taping, and sustainable adhesive solutions. |

| Bosch Packaging Technology (Syntegon Technology) | Provides high-speed automated case sealing solutions, AI-driven packaging line optimization, and food-grade sealing technologies. |

| Wexxar Bel (ProMach) | Focuses on customizable case sealing systems, AI-integrated quality control, and high-speed industrial packaging automation. |

| Lantech Inc. | Offers semi-automatic and fully automated case sealing solutions, AI-powered box sealing precision, and stretch wrapping systems. |

Key Market Insights

3M Company (18-22%)

Leading the case closures and sealers market, 3M provides AI-driven sealing technologies, high-durability adhesives, and automated packaging efficiency solutions in the manufacturing space.

Illinois Tool Works Inc. (12-16%)

ITW focuses on precision case sealing and adhesive application using AI and sustainable packaging solutions.

Bosch Packaging Technology (Syntegon) (10-14%)

Bosch offers top-of-the-line case sealing machines for high-speed, industrial-grade applications, including machine units optimized for automation in the world of artificial intelligence and very high food-grade adhesive applications.

Wexxar Bel (ProMach) (8-12%)

Focused on specialized packaging automation, Wexxar Bel integrates with its AI-powered sealing precision and smart case closure optimization.

Lantech Inc. (5-9%)

Providing automatic and semi-automatic sealing solutions, Lantech enables a speedy package and play well with AI-powered performance monitoring.

Other Key Players (30-40% Combined)

Several industrial packaging machinery firms, automation solution providers, and adhesive technology companies contribute to next-generation sealing innovations, AI-powered packaging optimization, and sustainable adhesive solutions.These include:

The overall market size for case closures and sealers market was USD 5.2 Billion in 2025.

Case closures and sealers market is expected to reach USD 9.3 Billion in 2035.

The demand for case closures and sealers is expected to rise due to increasing automation in packaging, growing e-commerce and retail sectors, and rising demand for efficient and secure sealing solutions in logistics and supply chains.

The top 5 countries which drives the development of case closures and sealers market are USA, UK, Europe Union, Japan and South Korea.

Fully-Automatic Machines and Food & Beverage Packaging to command significant share over the assessment period.

Pan Liner Market Analysis by Polyethylene (PE), Nylon, Polypropylene, Polyester, Polytetrafluoroethylene (PTFE) and Biodegradable Plastics Through 2035

Packaging Films Market Analysis by Product Type, Material Type and End Use Through 2035

Magnetic Closure Boxes Market Trends - Growth & Demand 2025 to 2035

Neoprene Coffee Sleeves Market Growth - Demand & Forecast 2025 to 2035

Mailer Boxes Market Growth – Demand & Forecast 2025 to 2035

Metal Aerosol Packaging Market Growth - Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.