Carbon Brush Market Share Analysis Outlook from 2025 to 2035

The global carbon brush market is expected to grow at a CAGR of 4.5% and reach USD 4,918.1 million by 2035. This growth is primarily due to the rising demand for efficient electrical conductivity solutions in industrial machinery, power generation, and automotive applications.

| Attribute |

Details |

| Projected Value by 2035 |

USD 4,918.1 million |

| CAGR during the period 2025 to 2035 |

4.5% |

Carbon brushes play a vital role in electrical motors, generators, and grounding devices, ensuring the efficient transfer of current with minimum energy loss. The growth in electric vehicles (EVs), increasing automation in industries, and developments in power generation technologies are driving market expansion. High-load and precision applications are also finding high-performance carbon materials such as silver graphite and electro graphite to be increasingly adopted.

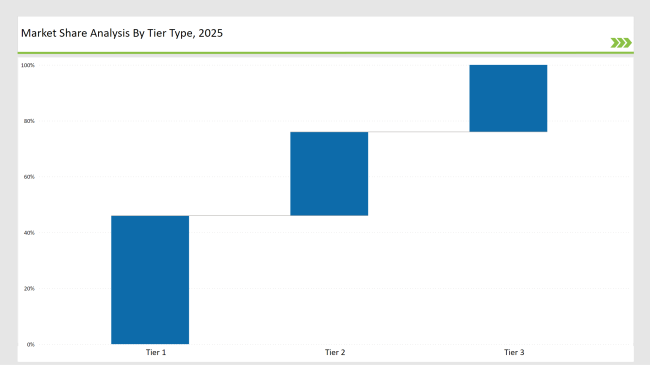

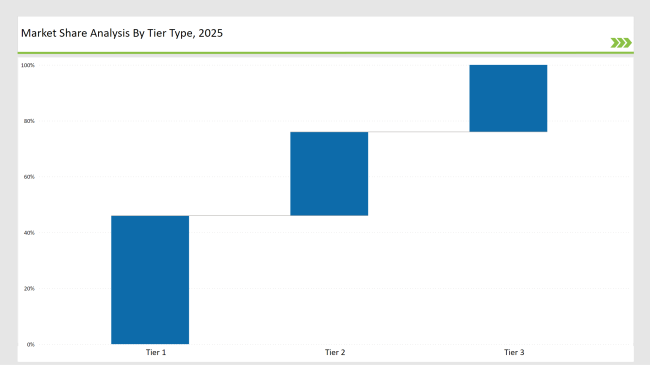

The market is still moderately concentrated, with Tier 1 players Mersen, Schunk Group, and Morgan Advanced Materials holding a total of 46% of the market share. Carbon graphite brushes are prominent in this market by having a market share of 33%, while the application has motor usage account for 40% demand, which is due to the reasons of wide use of brush motors in industrial and automotive sectors.

Explore FMI!

Book a free demo

Industry Landscape

| Category |

Industry Share (%) |

| Top 3 Players (Mersen, Schunk Group, Morgan Advanced Materials) |

32% |

| Next 2 of 5 Players(Helwig Carbon Products, Toyo Tanso Co. Ltd.) |

38% |

| Rest of the Top 10 |

30% |

The market is fairly consolidated, with leading companies focusing on high-performance carbon materials, extended brush life, and improved wear resistance.

Segmental Analysis

By Product Type

- Carbon Graphite (33% Market Share): Carbon graphite brushes dominate because of its well-balanced conductivity, durability, and wear resistance. These brushes are mainly applied in motors, generators, and transmission systems. Mersen and Schunk Group have significant strengths in carbon graphite solutions for industrial and automotive industries.

- Metal Graphite: Metal graphite is used in most high-current applications, such as welding generators and electric trains. These brushes are excellent in electrical conductivity as well as low resistance. Morgan Advanced Materials provides high-performance metal graphite brushes for heavy-duty electrical systems.

- Electro Graphite: Electro graphite brushes are used in high-speed applications, such as power tools, aerospace, and medical equipment. They have self-lubricating properties and high thermal stability. Helwig Carbon Products focuses on electro graphite brushes for precision machinery.

- Silver Graphite: Silver graphite brushes offer exceptional conductivity and low voltage drop, making them the best for aerospace, defense, and high-frequency applications. Toyo Tanso Co. Ltd. is focused on silver graphite brushes for precision control applications.

- Resin-Bonded Graphite: Graphite bonded with resin is applied mostly in low-load applications. There, less friction and wear under control are desired. Graphite bonded with resin is common in home appliances and low-power industrial equipment.

- General Graphite: Graphite general is used at low-intensity applications in domestic appliances and small motors.

By Application

- Motor (40% Market Share): Motors dominate the market since carbon brushes are a necessity in DC and AC motors used in automotive, industrial, and commercial applications. With the rise in electric vehicles and industrial automation, demand is also increasing. Mersen and Schunk Group are the leading providers of high-performance motor brushes for global automotive companies.

- Generator & Alternator: Generators and alternators require carbon brushes for effective power transmission and voltage regulation. The demand is high in power plants, renewable energy systems, and backup generators. Morgan Advanced Materials and Helwig Carbon Products offer long-lasting generator brushes.

- Current & Signal Transmission: These brushes ensure precise electrical signal transmission in aviation, railways, and robotics. Toyo Tanso Co. Ltd. specializes in low-resistance silver graphite brushes for critical signal transmission.

- Grounding Devices: Carbon brushes in grounding applications prevent electrical buildup and static charge damage. Used in industrial machinery, aerospace, and wind turbines, these brushes enhance system reliability and safety. Schunk Group supplies high-performance grounding brushes for high-voltage applications.

Who Shaped the Year?

Several key players contributed to market advancements in 2024

- Mersen: Developed high-density carbon brushes with extended wear life for high-speed industrial motors.

- Schunk Group:Launched low-resistance silver graphite brushes for precision signal transmission in defense and aerospace applications.

- Morgan:Advanced Materials expanded its high-durability generator brush portfolio for renewable energy and hybrid power systems.

- Helwig: Carbon Products introduced self-lubricating electro graphite brushes to enhance performance in high-temperature environments.

- Toyo Tanso Co. Ltd.:Focused on custom-engineered metal graphite brushes for railway electrification and automation.

Key Highlights from the Forecast

- Carbon Graphite Brushes Lead the Market: These brushes account for 33% of total demand, as they offer a balance of wear resistance, durability, and conductivity.

- Motors Drive the Highest Demand: The motor segment holds 40% of market demand, with industries shifting toward efficient carbon brush solutions for industrial and automotive applications.

- Advanced Materials Gain Popularity: The adoption of silver graphite and electro graphite is increasing in precision industries like aerospace and defense.

- Automotive Electrification Increases Demand: The transition to electric vehicles (EVs) and hybrid power systems is fueling demand for low-resistance, high-efficiency carbon brushes.

Tier-Wise Industry Classification

| Tier |

Examples |

| Tier 1 |

Mersen, Schunk Group, Morgan Advanced Materials |

| Tier 2 |

Helwig Carbon Products, Toyo Tanso Co. Ltd. |

| Tier 3 |

Regional and niche players |

Market KPIs

- Wear Resistance & Durability: The industry needs to have extended carbon brushes to save maintenance and operating cost.

- High Conductivity & Low Resistance: There is a rising demand for low-resistance brushes in the automotive and aerospace sector.

- Sustainability & Environmental Compliance: Carbon brushes are designed by manufacturers as an eco-friendly product, which can be recycled, thus minimizing waste and emissions.

- Customization & High-Precision Engineering: Companies are targeting engineered carbon brushes designed for application-specific industrial use.

Key Company Initiatives

| Company |

Initiative |

| Mersen |

Launched high-density carbon brushes for extended lifespan in industrial motors. |

| Schunk Group |

Launched low-resistance silver graphite brushes for precision applications. |

| Morgan Advanced Materials |

Expanded high-durability generator brush range for renewable energy systems. |

| Helwig Carbon Products |

Developed self-lubricating electro graphite brushes for high-speed applications. |

| Toyo Tanso Co. Ltd. |

Focused on custom-engineered metal graphite brushes for railway and automation systems. |

Recommendations for Suppliers

- Expand Advanced Material Offerings: High performance electro and silver graphite brushes would find acceptance.

- Cater to Growing EV Demand: Low-wear carbon brushes in electric vehicles and hybrid systems will find more traction.

- Improve Sustainability Practices:Develop recyclable and carbon brush solutions friendly to the environment to meet regulation requirements.

- Enhance Smart Brush Monitoring Systems: AI-integrated wear detection systems will optimize performance and maintenance cycles.

Future Roadmap

The carbon brush market will also grow significantly by 2035, driven by material innovation, advanced AI-based wear monitoring, and highly burgeoning demand for high-efficiency electrical solutions. Industries such as electric vehicles, renewable energy, and industrial automation will continue to expand, increasing the demand for durable, high-performance carbon brushes.

These technologies, such as metal graphite and resin-bonded composites, will improve carbon brush performance, efficiency, and durability to be applied in more severe operation. AI-powered wear monitoring systems will revolutionize the way carbon brushes are used, providing real-time insights into brush conditions and optimizing maintenance schedules to extend product life and reduce downtime.

In sectors like EVs, renewable energy (such as wind and solar power), and industrial automation, the growing emphasis on energy efficiency will further fuel the demand for advanced carbon brushes that meet the stringent requirements of these high-tech applications. As these trends unfold, the carbon brush market will witness significant innovation and expansion.

Frequently Asked Questions

Which Companies hold significant share in the Carbon Brush Market?

Mersen, Schunk Group, Morgan Advanced Materials command about 35% share in the overall market.

Which is the leading product segment in Carbon Brush Market?

Carbon Graphite have a market share of 33% of the overall market.

How much share does regional and domestic companies hold in the market?

Regional and domestic companies hold nearly 35% of the overall market.

How is the market concentration assessed in the Carbon Brush Market?

Market is fairly consolidated, representing top 10 players commanding significant share in the market.

By application which type offers significant growth potential to market players?

Motor holds the biggest share of 40% which will offer significant growth potential to market.