The bulk bag divider industry is experiencing strong growth due to increasing demand across industries such as agriculture, chemicals, construction, and food processing. Businesses require durable, customizable, and efficient solutions to improve material handling, storage, and transportation processes.

As companies focus on operational efficiency and sustainability, innovations in biodegradable materials, automated manufacturing, and reinforced dividers are driving industry transformation.

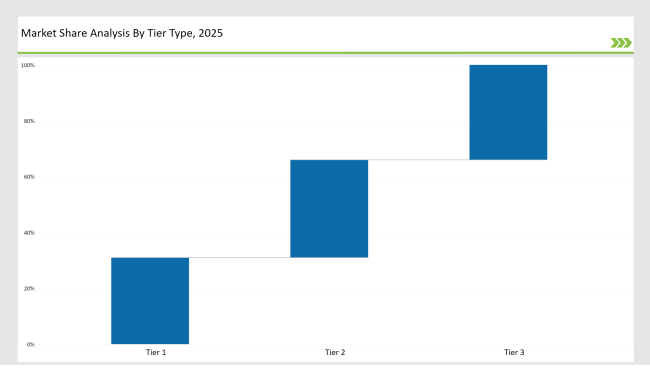

Tier-1: companies such as Greif, Berry Global, and LC Packaging lead with 31% market share due to their extensive product offerings, sustainability initiatives, and high-performance dividers.

Tier-2: companies including Conitex Sonoco, BAG Corp, and Bulk-Pack hold 35% of the market, offering cost-effective and adaptable solutions for mid-sized enterprises.

With a 34% market share, Tier-3: consists of regional and niche manufacturers specializing in eco-friendly and customized bulk bag divider solutions. These companies focus on localized production, lightweight yet durable materials, and enhanced logistics efficiency.

Exclusive Offer: 30% Off on Regional Reports

Get a free sample report and customize your regions for a 30% discount on your regional report!

Global Market Share by Key Players (2025)

| Category | Market Share % |

|---|---|

| Top 3 (Greif, Berry Global, LC Packaging) | 15% |

| Rest of Top 5 (Conitex Sonoco, BAG Corp) | 9% |

| Next 5 of Top 10 (Bulk-Pack, Intertape Polymer Group, AmeriGlobe, Rishi FIBC, JumboSack) | 7% |

The bulk bag divider market serves industries requiring high-durability, cost-effective, and sustainable solutions. The growing focus on material handling efficiency and environmental compliance is fueling adoption.

Manufacturers are optimizing strength, sustainability, and efficiency in bulk bag divider solutions.

The bulk bag divider industry is evolving through automation, sustainability, and material advancements. Companies are integrating AI-driven manufacturing, robotic-assisted production, and smart materials to enhance durability and reduce waste. Innovations in sustainable materials and biodegradable dividers are gaining traction, aligning with global sustainability goals.

Year-on-Year Leaders

Check Free Sample Report & Save 40%!

Select your niche segments and personalize your insights for smart savings. Cut costs now!

Bulk bag divider technology suppliers should emphasize innovation in material science, automation, and sustainability to stay competitive.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Greif, Berry Global, LC Packaging |

| Tier 2 | Conitex Sonoco, BAG Corp |

| Tier 3 | Bulk-Pack, Intertape Polymer Group, AmeriGlobe, Rishi FIBC, JumboSack |

| Manufacturer | Latest Developments |

|---|---|

| Greif | Launched biodegradable bulk bag dividers in March 2024. |

| Berry Global | Developed moisture-resistant dividers for agriculture in April 2024. |

| LC Packaging | Introduced lightweight, stackable dividers in June 2024. |

| Conitex Sonoco | Strengthened industrial-grade solutions for chemical packaging in July 2024. |

| BAG Corp | Innovated AI-driven production lines in August 2024. |

| Bulk-Pack | Released high-performance dividers for mining and construction in May 2024. |

| Intertape Polymer Group | Focused on eco-friendly manufacturing techniques in September 2024. |

| AmeriGlobe | Advanced in moisture-resistant solutions for bulk grain storage in October 2024. |

The competitive landscape in the bulk bag divider market is evolving as key players focus on automation, sustainability, and enhanced engineering for better material handling.

The industry will continue adopting AI-driven quality control, eco-friendly materials, and automated production systems. Smart dividers with tracking features will enhance supply chain visibility and compliance. The demand for durable, sustainable, and cost-efficient bulk bag dividers will rise as industries prioritize waste reduction and optimized logistics.

Leading players include Greif, Berry Global, LC Packaging, Conitex Sonoco, BAG Corp, and Bulk-Pack.

The industry is evolving with advancements in automation, sustainability, and customizable divider solutions.

The market exhibits medium concentration, with top players holding a significant market position.

Explore Packaging Formats Insights

View Reports

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.