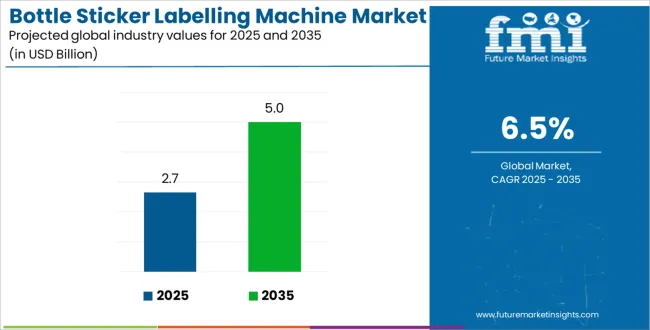

The Bottle Sticker Labelling Machine Market is estimated to be valued at USD 2.7 billion in 2025 and is projected to reach USD 5.0 billion by 2035, registering a compound annual growth rate (CAGR) of 6.5% over the forecast period.

The bottle sticker labelling machine market is witnessing steady expansion, supported by increasing demand for automation in packaging lines and heightened focus on product traceability and branding across industries such as food, beverage, pharmaceuticals, and personal care. The surge in small and mid scale manufacturing units has led to a higher requirement for compact, cost effective labelling solutions that offer operational efficiency without extensive infrastructure investment.

Global tightening of labelling regulations and consumer preference for visually appealing and informative packaging have compelled businesses to integrate reliable labelling systems that ensure precision and consistency. In response, machine manufacturers are prioritising modular designs, enhanced speed-to output ratios, and compatibility with diverse bottle shapes and label types.

The market is expected to grow further as the role of labelling transitions from mere identification to branding, compliance, and anti-counterfeiting all vital elements in competitive market environments.

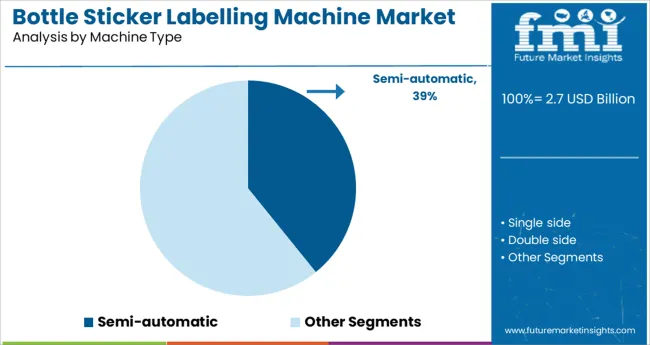

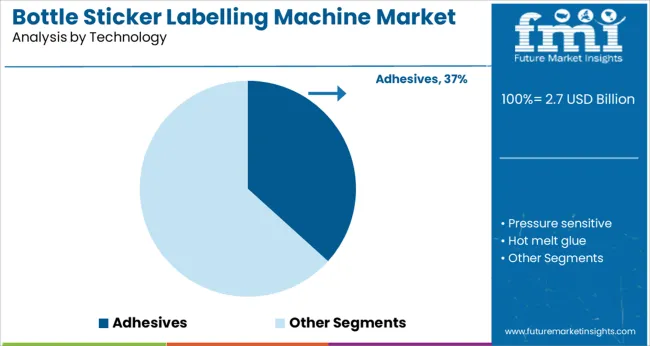

The market is segmented by Machine Type, Technology, and End-use Industry and region. By Machine Type, the market is divided into Semi-automatic, Single side, Double side, Automatic, Single side, and Double side. In terms of Technology, the market is classified into Adhesives, Pressure sensitive, Hot melt glue, Wet glue, Non-adhesives, Shrink labelling/ Sleeving, Roll-fed, and Others. Based on End-use Industry, the market is segmented into Food, Beverage, Personal & Home Care, Chemical, and Others.

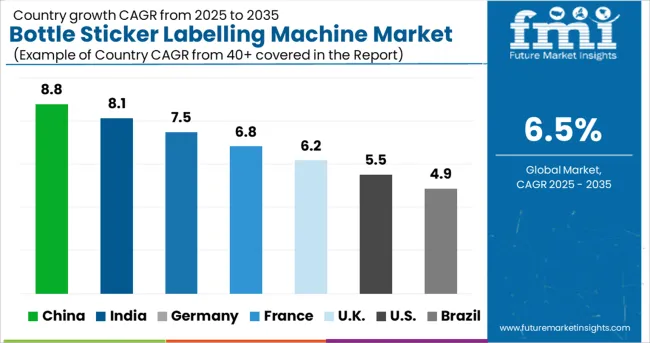

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

It has been observed that the semi-automatic machine type accounts for 39.20% of the total market revenue, positioning it as the leading segment within machine type. This leadership is attributed to its cost-efficiency, flexibility, and suitability for low- to medium volume production environments.

Semi-automatic machines are preferred by manufacturers seeking to enhance labelling precision while retaining manual control over the packaging process. The adoption has been strengthened by ease of operation, lower maintenance costs, and adaptability across multiple bottle sizes and shapes.

Additionally, small-scale producers and craft beverage brands have leveraged these machines to comply with labelling standards without incurring heavy capital expenditure. As businesses in emerging markets expand gradually, the demand for semi-automatic labelling solutions has increased, making this segment a pragmatic entry point for automation while preserving operator involvement.

It is noted that adhesive based labelling technology holds a 36.70% revenue share in the overall market, making it the dominant technology segment. This prevalence is driven by its versatility, ease of integration, and cost-effectiveness in both automatic and semi-automatic labelling systems.

Adhesive technology supports various label types including paper, film, and synthetic substrates, making it suitable for diverse packaging applications. Its widespread use has been reinforced by high speed application capabilities, minimal setup requirements, and strong bonding reliability across curved or irregular bottle surfaces.

Furthermore, innovations in pressure sensitive adhesives have improved performance under different environmental conditions such as moisture, refrigeration, and transport stress. This adaptability and proven track record in ensuring consistent label placement have positioned adhesive labelling as the technology of choice across both legacy and modern production lines.

The major firms operating in the global bottle sticker labelling machine market are segmented into three tiers based on their operating locations.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macroeconomic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global bottle sticker labelling machine market is estimated to be valued at USD 2.7 billion in 2025.

It is projected to reach USD 5.0 billion by 2035.

The market is expected to grow at a 6.5% CAGR between 2025 and 2035.

The key product types are semi-automatic, single side, double side, automatic, single side and double side.

adhesives segment is expected to dominate with a 36.7% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Bottle Sealing Wax Market Size and Share Forecast Outlook 2025 to 2035

Bottle Shippers Market Size and Share Forecast Outlook 2025 to 2035

Bottled Water Packaging Market Size and Share Forecast Outlook 2025 to 2035

Bottle Dividers Market Size and Share Forecast Outlook 2025 to 2035

Bottle Jack Market Size and Share Forecast Outlook 2025 to 2035

Bottles Market Analysis - Growth & Forecast 2025 to 2035

Market Share Distribution Among Bottle Dividers Suppliers

Bottle Carrier Market Trends – Growth & Forecast 2024-2034

Bottle Cap Market Analysis & Industry Forecast 2024-2034

Bottled Water Processing Equipment Market Trends – Growth & Industry Forecast 2025-2035

Bottle Pourers Market

Bottle Filling Machines Market Size and Share Forecast Outlook 2025 to 2035

Bottle Capping Machine Market Analysis by Automation, Operating Speed, Machine Type, End-use Industry, and Region Forecast Through 2035

RTD Bottled Cocktail Market - Size, Share, and Forecast Outlook 2025 to 2035

PET Bottles Market Demand and Insights 2025 to 2035

PCR Bottles Market Growth - Demand, Innovations & Outlook 2024 to 2034

Asia & MEA PET Bottle Market Trends & Industry Forecast 2024-2034

Foam Bottle Technology Market Size and Share Forecast Outlook 2025 to 2035

Beer Bottles Market Size and Share Forecast Outlook 2025 to 2035

Wine Bottle Sterilizer Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA