With a surge in industries focusing on lighter, longer lasting, and energy saving materials, the aluminum foam market is constantly developing. Aluminum foam is a very priced material with high strength to weight ratios and is extensively used within automotive, aerospace, construction, and energy industries, and by 2035 will attain a projected value of over USD 74.3 million, with an estimated compound annual growth rate of 4.5%.

Companies are in need of new manufacturing processes, recyclable materials, as well as improved performance attributes to address the different needs of varying industries. With the emphasis placed on sustainability and efficiency, aluminum foam is in a unique position as a transformative material for use in several industries.

| Attribute | Details |

|---|---|

| Projected Value by 2035 | USD 74.3 million |

| CAGR during the period 2025 to 2035 | 4.5% |

Explore FMI!

Book a free demo

Summary

The SWOT analysis shows the competitive strengths and strategies of leading companies in the aluminum foam market. Industry leaders like Cymat Technologies, ERG Aerospace, and Alusion are growing through innovation, global distribution, and ecofriendly practices. However, high production costs and limited market awareness create opportunities for technological advancements and diversification.

Cymat Technologies

Cymat excels in the production of advanced aluminum foam for automotive and defense applications. Its innovative approach and global presence strengthen its market position. However, high production costs remain a challenge. Expanding into emerging markets offers significant growth potential.

ERG Aerospace

ERG Aerospace is a leader in manufacturing highperformance aluminum foam for aerospace and energy. It has a strong supply chain and emphasizes customization, which allows it to maintain leadership in the market. The limitation of product diversification may reduce growth, but investment in sustainable materials may unlock new opportunities.

Alusion

Alusion specializes in aesthetically beautiful and highly durable aluminum foam. It has found strength in architectural and industrial solutions. The big challenges lie with the high costs of operations; on the other hand, high demand for lightweight material has big potential.

| Category | Market Share (%) |

|---|---|

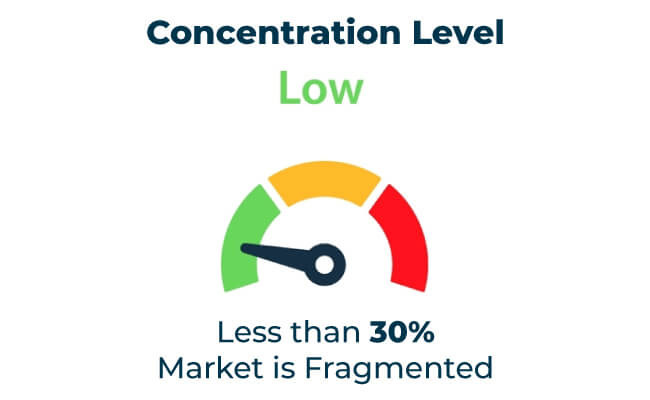

| Top 3 Players | 13% |

| Rest of Top 5 Players | 7% |

| Next 5 of Top 10 Players | 5% |

Type of Player & Industry Share

| Type of Player | Market Share (%) |

|---|---|

| Top 10 Players | 25% |

| Next 20 Players | 44% |

| Remaining Players | 26% |

Year over Year Winners

New opportunities are opening up in Africa, Southeast Asia and Latin America. The demand for energy efficient aluminum foam will rise with infrastructure development and industrialization. Exporters who can provide innovative and cost-effective solutions lead the competition.

InHouse vs. Outsourced Manufacturing

Diversely, the aluminum foam market reflects regional trends as it is induced by industrial growth, sustainability goals, and consumer preferences. Regional demands can only be maximally tapped by a company if their offerings are matched to the said demands.

| Region | North America |

|---|---|

| Market Share (%) | 35% |

| Key Drivers | Demand for lightweight materials in automotive. |

| Region | Europe |

|---|---|

| Market Share (%) | 30% |

| Key Drivers | Leadership in recycling and sustainable design. |

| Region | Asia-Pacific |

|---|---|

| Market Share (%) | 25% |

| Key Drivers | Rapid industrialization and construction growth. |

| Region | Other Regions |

|---|---|

| Market Share (%) | 10% |

| Key Drivers | Infrastructure development in emerging markets. |

The aluminum foam market will grow based on new production technologies, green environment projects, and global markets. The future market leaders will be those firms that are innovative and align with environmental goals.

| Tier | Key Companies |

|---|---|

| Tier 1 | Cymat Technologies, ERG Aerospace, Alusion |

| Tier 2 | Evonik Industries, Hydro Extrusion |

| Tier 3 | Foamtech, Beijing Zhongshi |

The market for aluminum foam is headed for spectacular growth, with demands for lightweight, re Conclusioncyclable, and totally durable solutions. Companies are going to capture the future market with their focus on advanced technologies as well as in international markets penetration. The additional scope for collaboration lies in the area of partnership with automobile, aerospace, and construction sectors.

Key Definition

Methodology

This report compiles data through primary research, secondary collection of data, and advice from experts. It also verifies with interviews of a few industry people and endusers to ascertain correctness and authenticity.

Market Definition

The aluminum foam market is the production and use of lightweight, cellular materials designed for energy absorption, insulation, and durability. It is a market of innovation, sustainability, and versatility.

Driving Factor: Rising usage of lightweight yet strong and highly energyefficient products.

The market size to be surpassed above USD 74.3 million in size with at a CAGR of 4.5%.

Market Leaders Cymat Technologies, ERG Aerospace, and Alusion.

There are two big challenges. They are high production costs and very low market awareness.

Emerging opportunities related to green products and advanced manufacturing technologies offer great scope in the market.

Korea Tape Dispenser Market Analysis by Material, Product Type, Technology, End Use, and Region through 2025 to 2035

Medical Transport Box Market Trend Analysis Based on Material, Capacity, End-User and Regions 2025 to 2035

Japan Heavy-duty Corrugated Packaging Market Analysis based on Product Type, Board type, Capacity, End use and City through 2025 to 2035

Corrugated Board Market Analysis by Material and Application Through 2035

Waterproof Packaging Market Trends - Demand & Industry Forecast 2025 to 2035

Thermochromic Labels Market Insights - Innovations & Growth 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.